Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

Optical conversion kit 67

13. Install the four nuts on the hydraulic cylinder tie rods. Double check the o-rings on each

end of the hydraulic cylinder tube to make sure they are in place. Tighten the nuts

evenly to bring the hydraulic cylinder tube and flanges together. Torque to

specifications listed inTable 4-3.

Tip: To ensure proper alignment of the hydraulic cylinder, use a level to verify the alignment with

the flow tube.

14. Connect the nitrogen supply hose from the spring plenum and the hydraulic hoses to

the hydraulic cylinder.

15. Install the operating handle on the nitrogen shut-off valve. Open the shut-off valve and

check for and eliminate any leaks.

16. Once the prover is fully assembled, check the hydraulic reservoir for proper level. Turn

on the power and start the hydraulic system motor. Check for and eliminate any

hydraulic system leaks. Once all air is eliminated from the hydraulic system, turn off the

motor and re-check the reservoir for proper level.

4.5 Optical conversion kit

Compact provers purchased prior to June 1989 are designed with a ‘shotgun’ style optical

assembly. These older provers may be retrofitted to accommodate the new ‘plug style’ optical

assembly. Installation instructions are provided with the kit. Switch replacement on the new

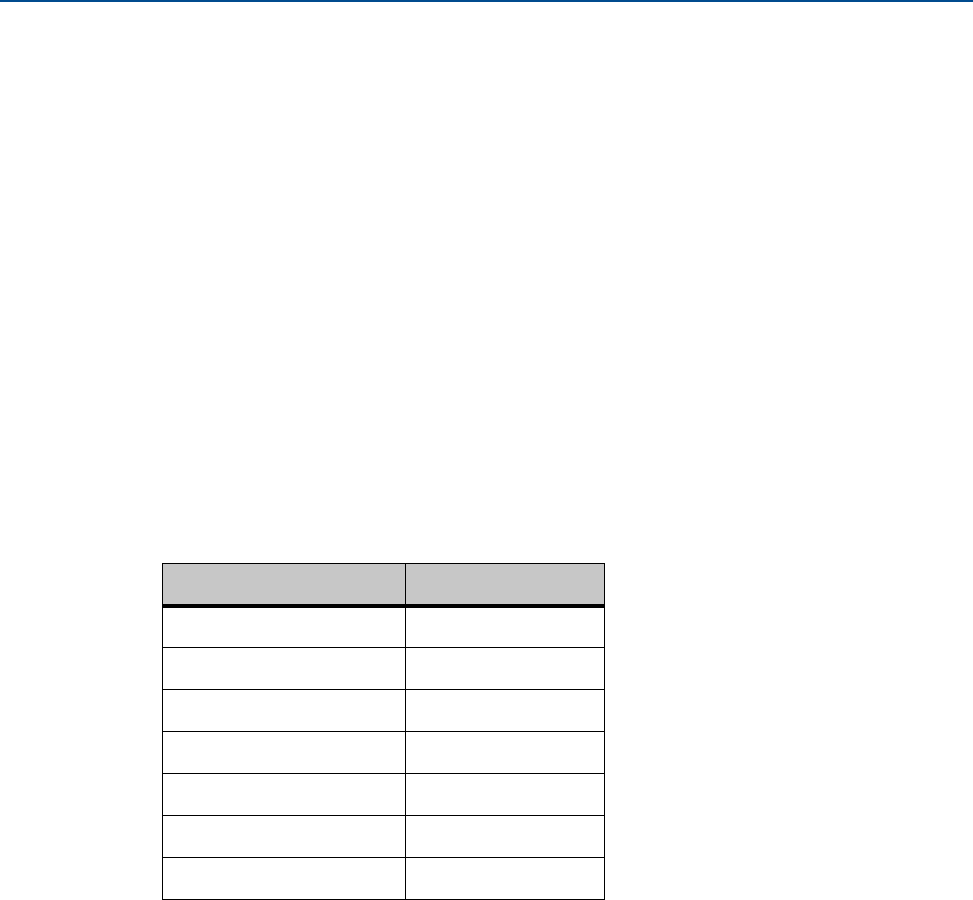

Table 4-3 Hydraulic cylinder tie rod nut torque

Prover size Torque value

8”

25 ft lbs (34 Nm)

12” Mini

45 ft lbs (61 Nm)

12”

45 ft lbs (61 Nm)

18”

125 ft lbs (170 Nm)

24”

220 ft lbs (299 Nm)

34”

600 ft lbs (814 Nm)

40”

1,400 ft lbs (1900 Nm)