54 Measurement Piston and Flow Tube

Section 4: Maintenance Operating and maintenance instructions

January 2015 3-9008-701 Rev J

3. Place the pieces of guide conduit (used in disassembly) through the upstream flange

and flow tube.

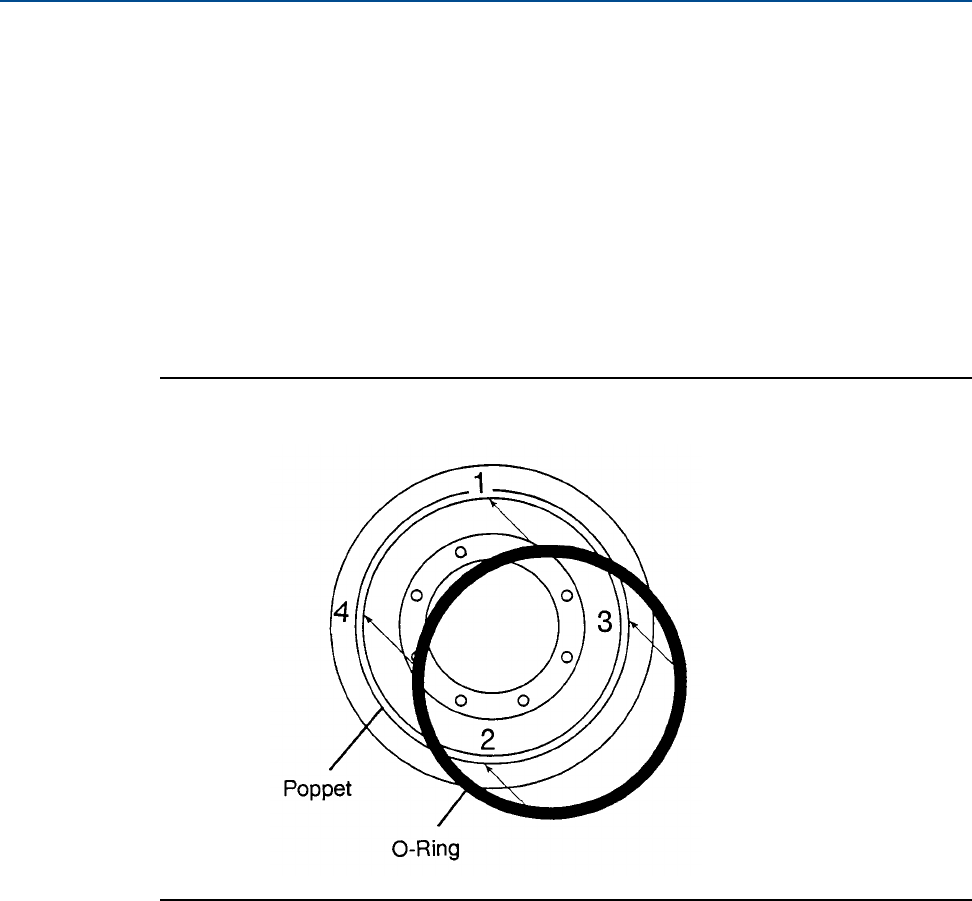

4. Lubricate the poppet valve o-ring and fit it onto the groove in the poppet valve. It is

recommended that the o-ring be pressed into the groove in places 90. apart to help

eliminate any twisting or stretching. See Figure 4-8. Care must be taken when working

the seal into the poppet groove as the seal may stretch and not seat correctly. The use

of a smooth plastic tool may assist in working the seal into the poppet groove. Working

the seal on opposite sides of the groove every few inches will assist in proper

installation. Use care to prevent damage to the o-ring.

Figure 4-8 Poppet O-ring installation