Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

Hydraulic Cylinder and Hydraulic Seal Support 63

8. After achieving proper alignment of the optical system, install the o-ring and the cover

tube. The cover should be positioned with the boss on the side.

9. Install the brace from the support bar to the optical assembly.

10. If calibration is required, proceed to Section 4.4.2, if not, see Section 2.4.

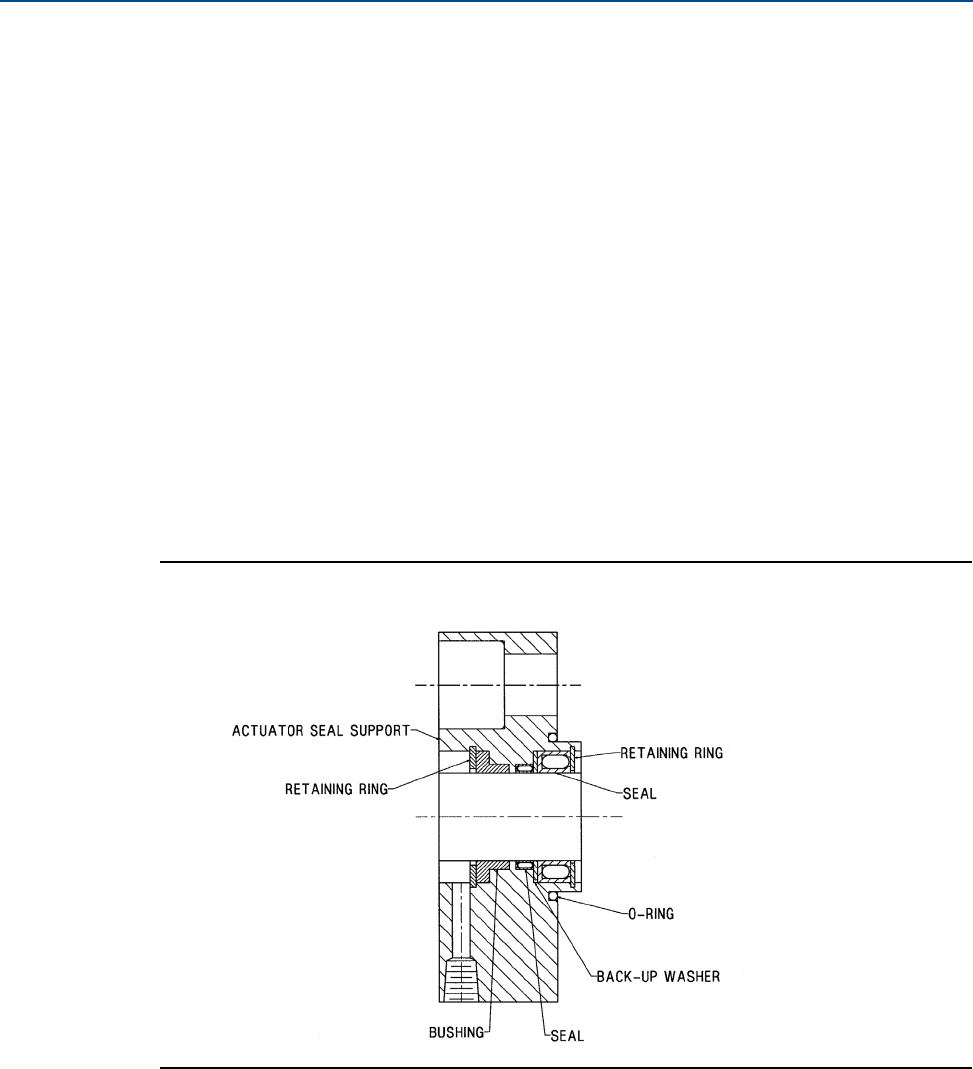

4.4.3 Hydraulic Cylinder and Hydraulic Seal Support

To determine if any of the seals in the hydraulic cylinder or the hydraulic seal support are in need

of replacement, check the weep hole at the bottom of the seal support. If line product is leaking

from the weep hole, the support seals are in need of replacement. If there is hydraulic fluid

leaking from the weep hole, the seals internal to the hydraulic cylinder are in need of inspection

for possible replacement.

Disassembly

ReferencesFigure 4-11 and Figure 4-12

Figure 4-11 Hydraulic seal support assembly

1. Close the spring plenum shut-off valve to the hydraulic cylinder and remove the valve’s

handle. This will prevent accidental opening of the spring plenum and loss of the

nitrogen within.

2. Loosen the Nitrogen supply line at the end of the hydraulic cylinder. Allow the gas in the

supply line to escape.