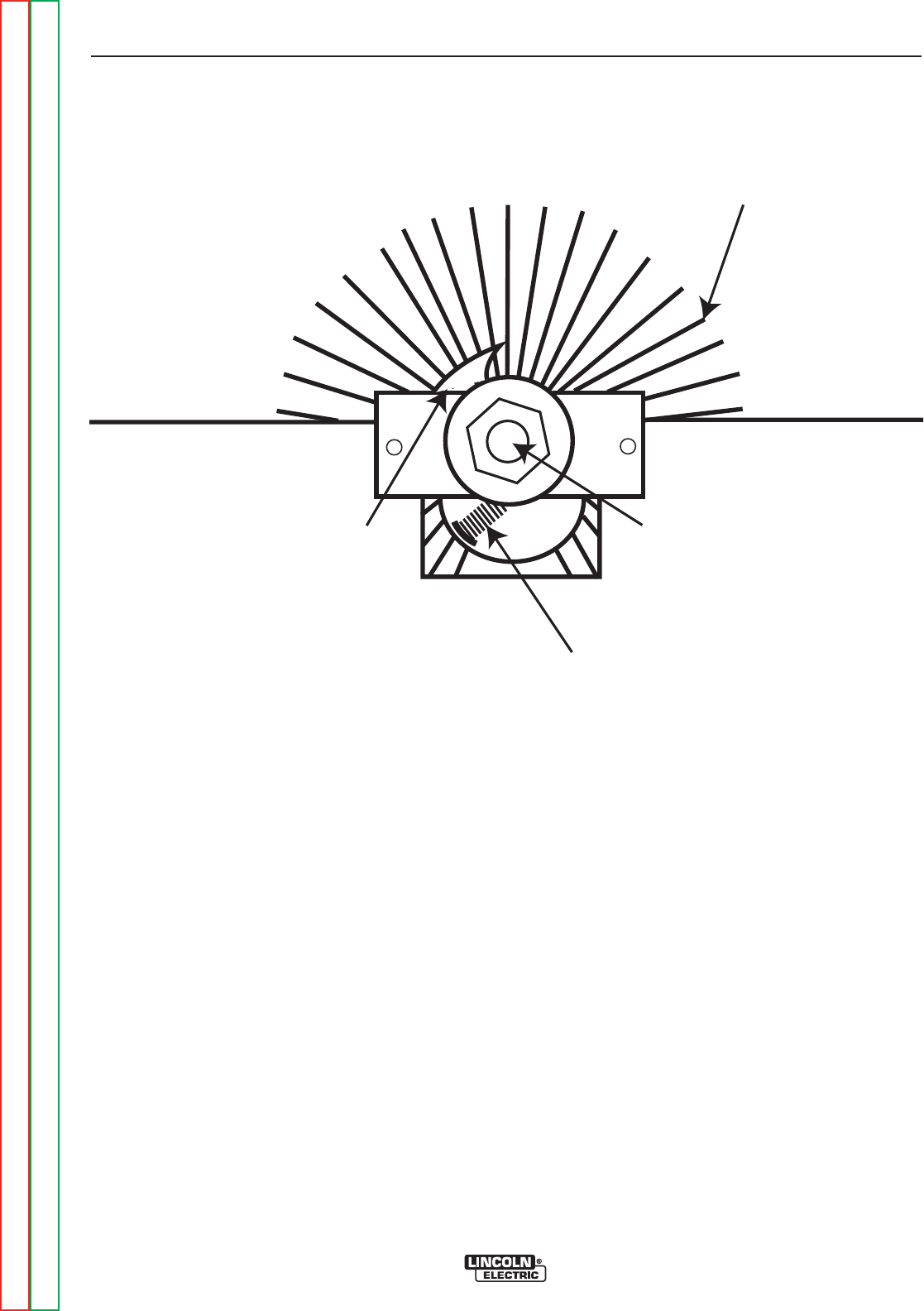

WINDING

Contacts &

Springs

Output Stud

Assembly

Brush

Holder

Assembly

FIGURE F.19 – BRUSH & SPRING

OUTPUT CONTROL UNIT (VARIABLE REACTOR)

INSPECTION AND SERVICE PROCEDURE (continued)

PROCEDURE

1. Turn the engine off, open the doors on the control

panel end of the machine and disconnect the nega-

tive battery cable. The doors must be secured while

disconnecting the battery cable.

WARNING: Secure the doors in the open position

using the door restraint system. If the

machine does not have a door restraint

system, remove the doors or securely

restrain them to prevent them from falling

closed.

2. Remove the roof and doors.

3. Inspect the output control unit:

4. Carefully examine the unit. Check for arc damage,

missing or broken springs, burned and/or badly

worn contacts. Also look for missing or damaged

insulators, poor lead connections, and damaged

lead insulation. If there is serious damage to the

inside diameter of the winding, the Output Control

Unit should be replaced. See Figures F19 and F.20.

5. Disassemble the continuous control unit:

If service is necessary, remove the fuel tank and dis-

connect the heavy cable attached to the output stud, at

the center back on the output control.

6. Remove the Output control handle.

7. Remove the two screws holding the Brush holder

stud assembly. Use caution, the shaft is under

spring tension. The stud assembly and the rotating

brush holder/contact assembly can now be

removed through the back of the unit. See Figures

F19 and F.20.

TROUBLESHOOTING AND REPAIR

F-60 F-60

SAE-400 SEVERE DUTY

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC