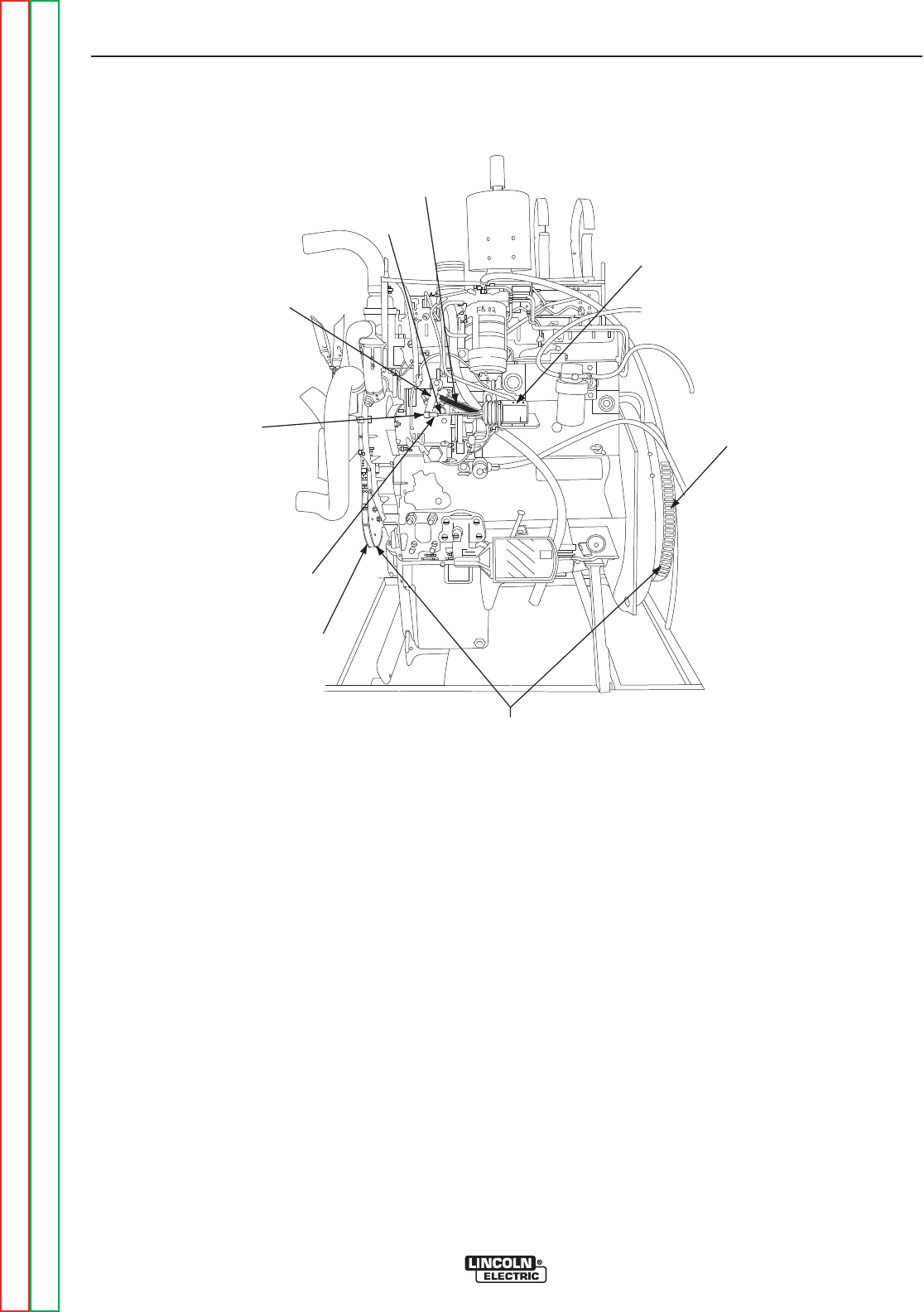

Idler

Solenoid

Spring

Idler Rod

Speed

Control

Lever

Ball

Joint

Lock

Nut

Pulley

Fan Blades

Possible Strobe-Tach

Mark Points

FIGURE F.1 – ENGINE COMPONENTS (CODE 10856)

ENGINE RPM ADJUSTMENT TEST (continued)

TEST PROCEDURE

1. Turn the engine off

2. Open the left side door, on the engine end of the

machine.

WARNING: Secure the door in the open position using

the door restraint system. If the machine

does not have a door restraint system,

remove the door or securely restrain it to

prevent it from falling closed.

3. Check that the linkage attaching the solenoid to the

engine speed control lever is properly aligned and

in good condition. It is more important that the sole-

noid linkage be more precisely aligned when in the

high speed (de-energized position). See Figures

F.1 and F. 2.

Strobe-Tach Method:

1. Place a highly visible mark on the engine crankshaft

pulley, or another rotating component connected to

the engine crankshaft. See Figure F.1.

2. Connect the strobe-tach according to the manufac-

turer’s instructions.

3. Start the engine and place the idle switch in the

“HIGH IDLE” position. Apply a resistive load operat-

ing the machine at 100% output (400 amps @ 36

volts) for about 30 minutes to get the machine up to

operating temperature and the RPM to stabilize.

CAUTION: Do Not Short the Output Studs Together

as a means of loading the machine.

Serious damage can result that will not

be covered by Warranty.

4. Direct the strobe-tach light on the highly visible

mark that had been applied earlier and synchronize

the light with the rotating mark. See the strobe-tach

manufacturer’s instructions.

TROUBLESHOOTING AND REPAIR

F-22 F-22

SAE-400 SEVERE DUTY

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC