THEORY OF OPERATION

E-3 E-3

SAE-400 SEVERE DUTY

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

AUTOMATIC ENGINE IDLE SYSTEM

The automatic idle system reduces the engine RPM

when there is no electrical demand on the machine.

When an arc is struck, or a load of 100 Watts or greater

is applied to the auxiliary output, the engine speed will

immediately increase to high RPM. When the load is

released, the engine continues to run at high RPM for

about 12 seconds. If a load is re-applied during this

time, the machine will continue to operate at high RPM.

If no load is applied, the engine RPM is reduced to idle

speed.

The automatic idle system functions by energizing a

solenoid, which pulls the engine speed control to a pre-

set low idle RPM position. When this solenoid is de-

energized, the engine speed is controlled by the gov-

ernor which maintains the engine RPM at the specified

high RPM setting. The solenoid is supplied with

+12VDC power whenever the idle switch is in the auto

position. It is activated when circuitry on the

Idler/engine shutdown PC board completes the sole-

noid’s path to chassis ground.

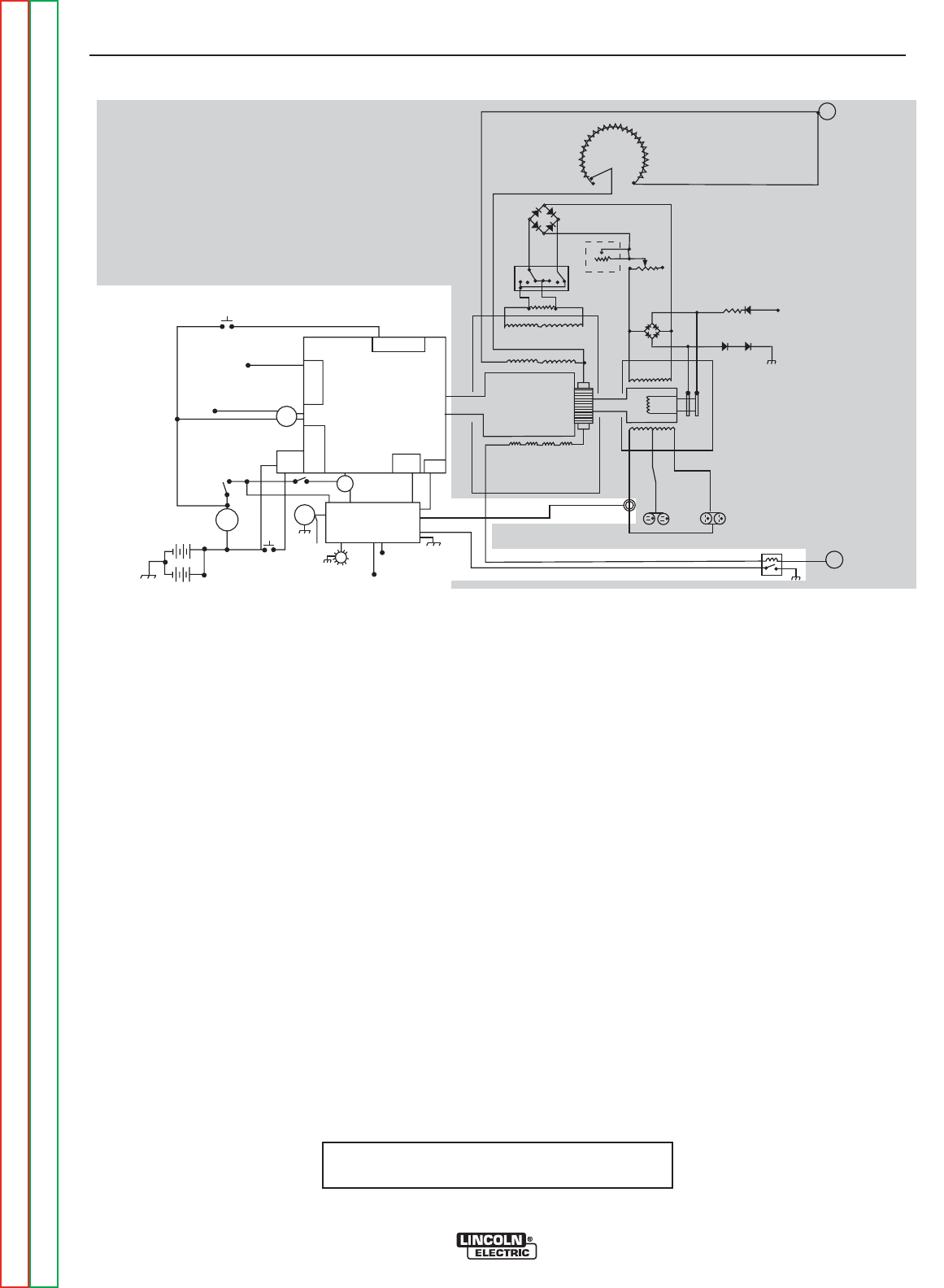

FIGURE E.2 - ENGINE STARTING AND PROTECTION

The automatic idle circuitry on the PC board uses a

magnetic reed switch to sense weld current and a

toroidal current transformer to sense auxiliary current.

When weld current flows the reed switch closes, con-

necting the sense lead to chassis ground. When suffi-

cient AC current flows, the toroidal current transformer

sends a signal to the PC board.

When the idle switch is in the “high” position, power to

the solenoid is shut off deactivating it and causing the

engine to operate at high rpm. The idle circuitry on the

PC board continues to sense if there is a load on any

of the outputs, and continues to open and close the

solenoid’s ground path.

If the machine had been operating at low idle and the

idle switch is moved from auto to high, the engine RPM

will increase immediately. If the switch is moved from

high to auto, the engine RPM may be reduced imme-

diately or it could take up to 12 seconds for the idle cir-

cuitry on the PC board to activate and engage the sole-

noid.

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

---

DIESEL

ENGINE

THERMOSTAT

INJECTION

PUMP

SOLENOID

SYSTEM

THERMOSTART

BUTTON

IDLE SWITCH

IDLE

SOLENOID

IDLE / ENGINE

PROTECTION BOARD

TO IDLE / ENGINE

PROTECTION BOARD

RUN/STOP

SWITCH

S

T

A

R

T

E

R

TO IDLE/ENGINE

PROT. BOARD

OIL

PRESSURE

SWITCH

TEMP

SWITCH

STARTER

SOLENOID

AMMETER

START

BUTTON

ENGINE

FAULT

LIGHT

HOUR

METER

TO

FLASHING

RESISTOR

AND

DIODE

INTERPOLE COILS

GENERATOR

ARMATURE

SERIES COILS

SHUNT COILS

115 VAC

RECEPTACLES

230 VAC

RECEPTACLES

AUXILIARY

POWER

WINDINGS

EXCITER

WINDING

EXCITER

ROTOR

MIN

(OFF)

MAX

OUTPUT

CONTROL

ELECTRODE

TERMINAL

RESISTOR

POLARITY

SWITCH

REMOTE

RHEOSTAT

LOCAL

RHEOSTAT

(JOB SELECTOR)

TO HOUR METER

FLASHING

RESISTOR AND

DIODE

(+)

(+)

(-)

(-)

AC

AC

(-) (+)

WORK

TERMINAL

TO ALTERNATOR

FLASH/SENSE

TO INJECTION

PUMP SOLENOID