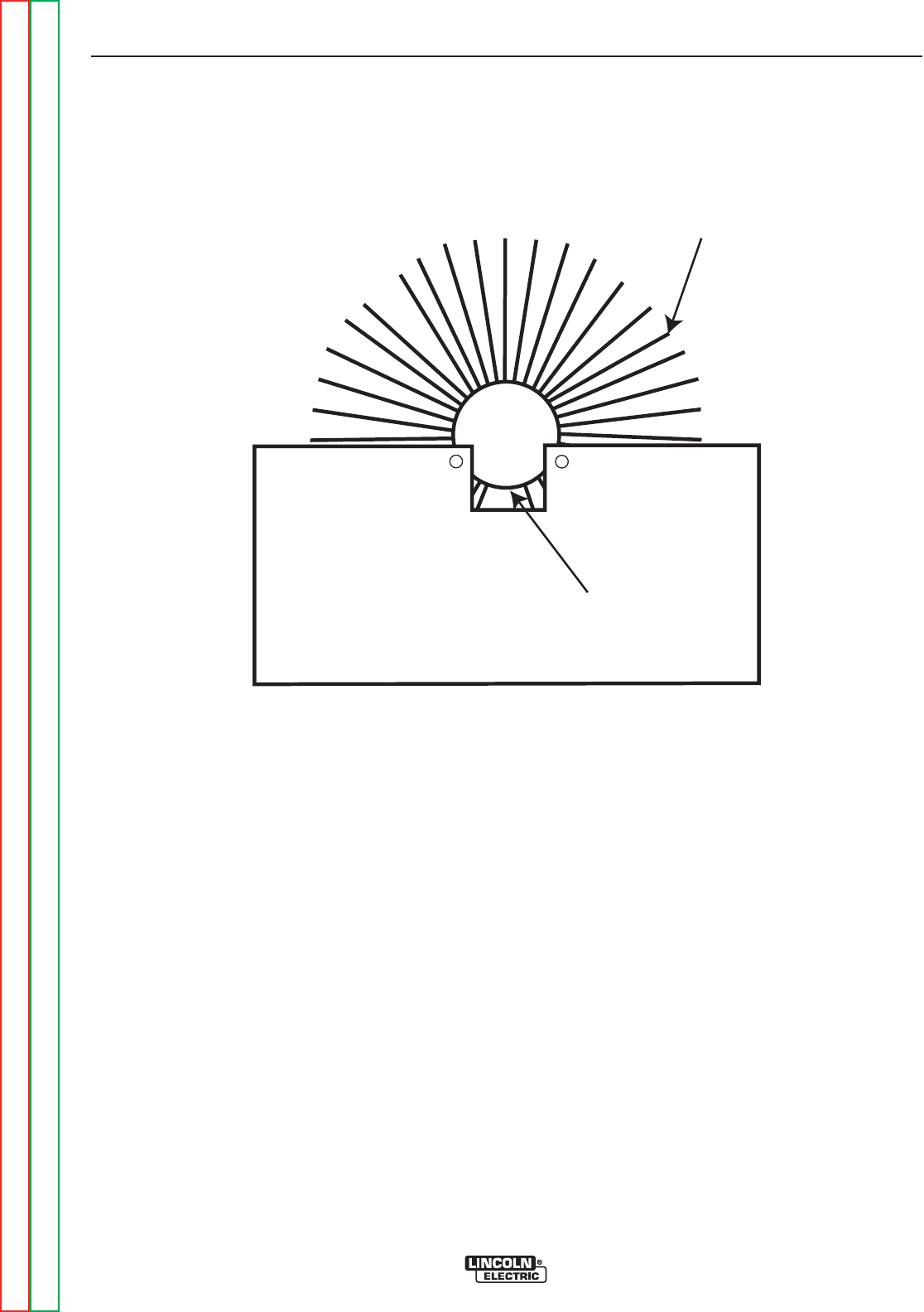

WINDING

INSULATED

WEDGE

FIGURE F.20 – BRUSH & SPRING

OUTPUT CONTROL UNIT (VARIABLE REACTOR)

INSPECTION AND SERVICE PROCEDURE (continued)

PROCEDURE (continued)

Servicing the continuous control unit:

8. Clean the continuous output control unit by using

low pressure air to remove any excess dust and dirt.

If the unit is greasy or oily, a more thorough clean-

ing will be required. The unit must be clean and

completely dry before continuing.

9. Ground test the unit by testing the resistance

between the following points:

• Chassis ground to winding

• Chassis ground to the insulated steel wedge (at

the bottom of continuous output control inside

diameter)

• Insulated steel wedge to the winding. See Figure

F.20 .

The resistance should be very high, 500,000 (500k)

Ohms min.

If the resistance is too low, disconnect the remaining

connection cable and look for any connection with

chassis ground, including any buildup of conductive dirt

contacting the winding. Repeat the above resistance

tests. If the low resistance is determined to be within

the continuous output control unit, it will need to be

replaced.

Use very fine, 400 to 600 grit sand paper or a cylinder

hone to clean away any dirt, oxidation, or minor arc pit-

ting from the output control bore.

TROUBLESHOOTING AND REPAIR

F-61 F-61

SAE-400 SEVERE DUTY

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC