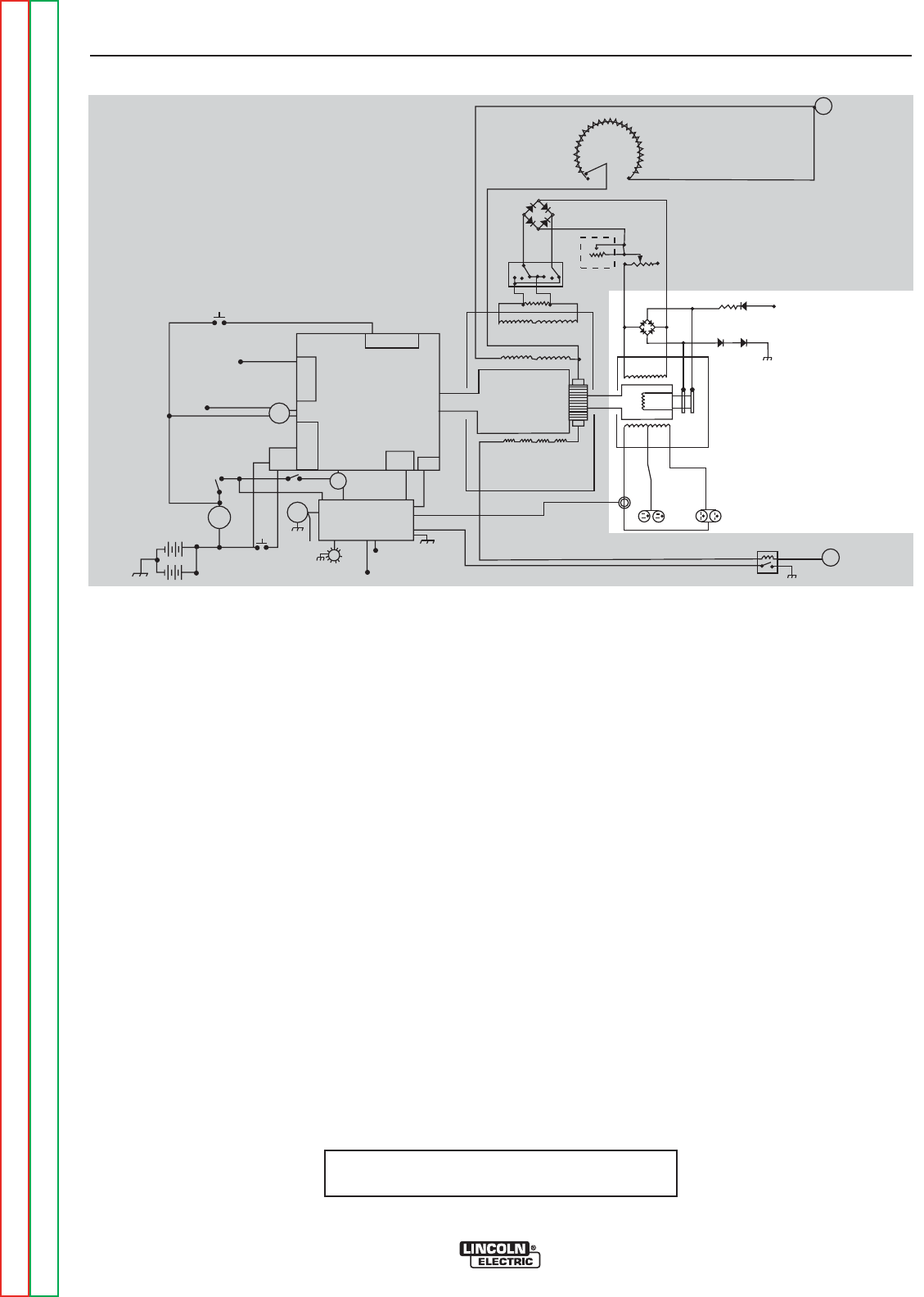

THEORY OF OPERATION

E-9 E-9

SAE-400 SEVERE DUTY

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WELDING GENERATOR OPERA-

TION (Continued)

Interpole coils:

Armature current from the remaining two sets of brush-

es is routed through four interpole coils, before being

connected to the weld output terminal. These coils are

narrower than the shunt and series coils, and are locat-

ed in the generator stator between them. Their purpose

is to reduce distortion of the magnetic field.

The magnetic field generated by the the shunt coils will

become distorted when current is drawn from the

armature. This distortion will increase as the current

flow increases. The interpole coils are connected and

arranged to counteract this magnetic distortion. If not

corrected, the distortion would cause reduced output

and excessive sparking on the commutator.

FIGURE E.2 - GENERAL DESCRIPTION

DIESEL

ENGINE

THERMOSTAT

INJECTION

PUMP

SOLENOID

SYSTEM

THERMOSTART

BUTTON

IDLE SWITCH

IDLE

SOLENOID

IDLE / ENGINE

PROTECTION BOARD

TO IDLE / ENGINE

PROTECTION BOARD

RUN/STOP

SWITCH

S

T

A

R

T

E

R

TO IDLE/ENGINE

PROT. BOARD

OIL

PRESSURE

SWITCH

TEMP

SWITCH

STARTER

SOLENOID

AMMETER

START

BUTTON

ENGINE

FAULT

LIGHT

HOUR

METER

TO

FLASHING

RESISTOR

AND

DIODE

INTERPOLE COILS

GENERATOR

ARMATURE

SERIES COILS

SHUNT COILS

115 VAC

RECEPTACLES

230 VAC

RECEPTACLES

AUXILIARY

POWER

WINDINGS

EXCITER

WINDING

EXCITER

ROTOR

MIN

(OFF)

MAX

OUTPUT

CONTROL

ELECTRODE

TERMINAL

RESISTOR

POLARITY

SWITCH

REMOTE

RHEOSTAT

LOCAL

RHEOSTAT

(JOB SELECTOR)

TO HOUR METER

FLASHING

RESISTOR AND

DIODE

(+)

(+)

(-)

(-)

AC

AC

(-) (+)

WORK

TERMINAL

TO ALTERNATOR

FLASH/SENSE

TO INJECTION

PUMP SOLENOID

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion