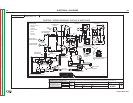

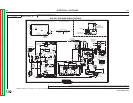

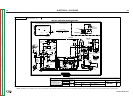

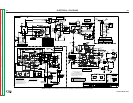

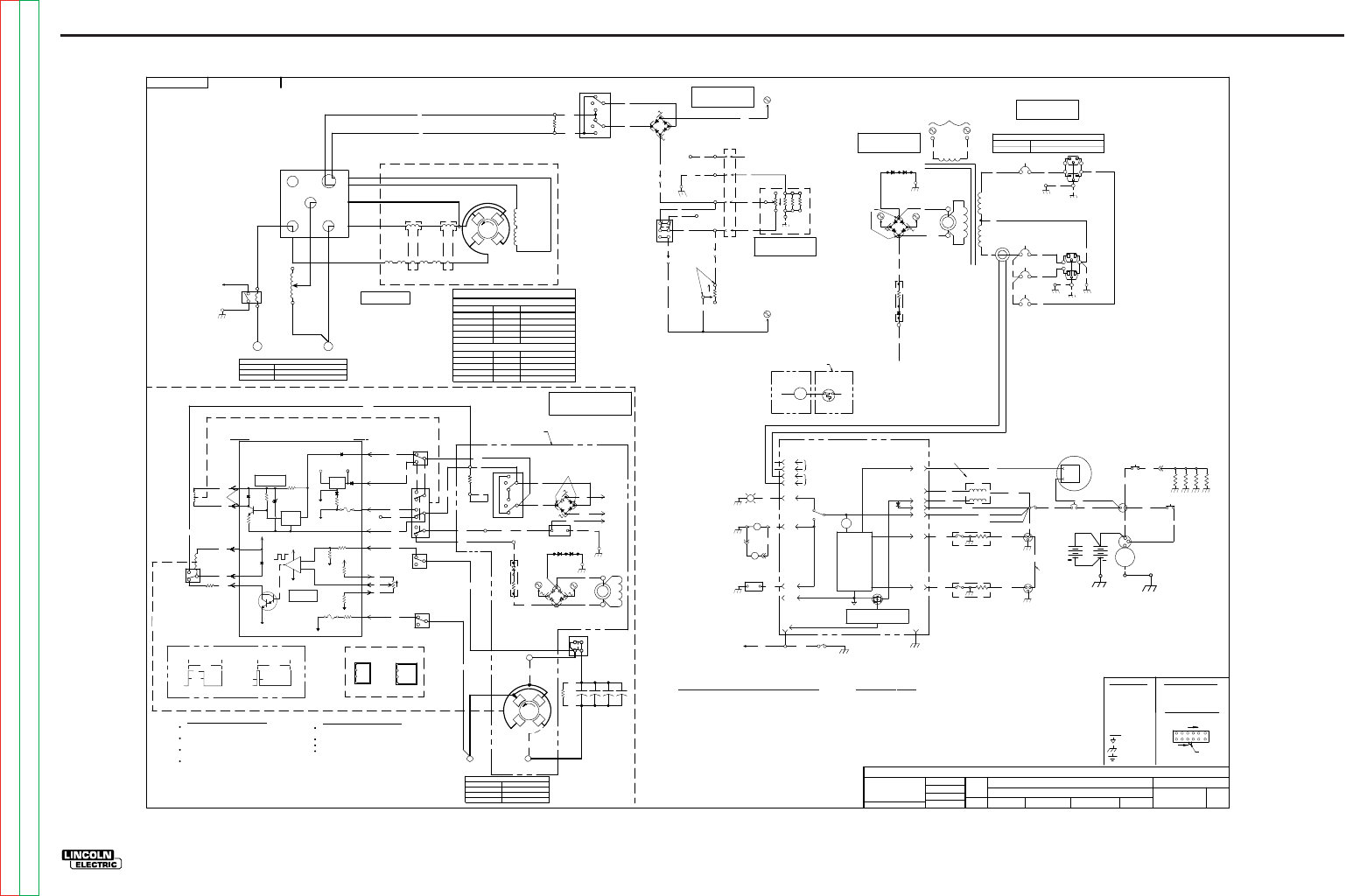

ELECTRICAL DIAGRAMS

G-8

SAE-400 SEVERE DUTY

®

SCHEMATIC - COMPLETE MACHINE - CODE 11199 (G4924)

EN-170

S

O

L

ID

E

D

G

E

G4924

SAE-400

MAC

HI

N

ESC

HEM

ATIC

NONE

-

DO NO

T

SC

AL

E

T

HIS DR

A

WING

EQ

UIP

M

ENT

TYPE:

SUBJECT:

SCA

L

E:

NA

CRM38346

1

PAGE ___ OF

___

1

E

NGI

N

EE

RI

NG

CO

NT

RO

LLE

D

MA

NU

FA

CT

URE

R:

No

THIS DOCUMENT CONTAINS PROPRIETAR

Y

INFORMATION OWNED B

Y

LINCOLN GLOBA

L, INC.

AND MA

Y

NOT BE DUPLICATED, COMMUNICATED

TO O

THER PARTIES OR US

ED FOR

AN

Y

PURPOS

E WITHOU

T

THE EXPRES

S WRIT

TEN PERMISSION

OF LINCOLN GLOBAL, INC.

PRO

PRIETARY & C

ONFIDENTIAL:

t

MAT

ERI

A

LTO

L

ER

ANC

E("

"

)TOA

GR

EE

WITH

PU

B

LI

SH

ED

ST

ANDARD

S.

ON A

LL

AN

GL

E

SI

S ± .5 OF

AD

E

GR

EE

ON

3

PLACE

D

E

CIM

ALS

IS

±.

00

2i

n.

(

±

0.

0

5

mm)

ON 2

PL

AC

ED

ECIM

AL

SI

S ± .02 in. (

±

0.5 mm)

UNLESS OTHERWISESPECIFIED TOLERANCE:

M

ANUF

ACTURING TO

L

ER

ANC

E

P

ER

E

2056

R

evi

sed

CHAN

GE

D

ET

AIL:

REFER

ENCE:

MA

T

ERI

AL

DIS

PO

SI

T

ION:

AP

PRO

VA

L

DA

T

E:

PROJ

EC

T

NUMBER:

DOCUMEN

T

NUMBER:

DOCUMEN

T

REV

ISI

ON:

IF PR

IN

T

ED

@A

1

SIZ

E

UNI

T

S:

IN

CH

1/1/

2000

Ma

gli

e

tt

a

D. B

ENDER

-

DRAWN BY:

ENGINEER:

CLE

VE

L

AND

APPROVED:

CONTROL:

D

G4924

LE

A

D

C

OL

O

R

COD

E:

B-

BL

AC

K

O

R

GRAY

G-

GRE EN

O-

OR ANGE

R-

RE

D

O

R

PI

NK

U-

BL

UE

W-

W

HIT

E

Y-

Y

ELL

OW

C

OM

PONE

NT

V

AL

U

E

U

NIT

S:

CAPA

CIT

O

R: MF

D/

V

OLT

S

RE

SI

ST

O

R:

O

HM

S/

W

ATT

S

CO NNE

CT

O

R

PI

N

N

UM

BER

S:

VIEW

OF

CONNEC

TO

RONPCBOARD

1

2

6

7

12

EX.

12

PIN CONNEC

TO

R

LABELS

:

C

OMM

ON

FR

AM

E

GROUND

EA

RT

H

GROUND

AU

XILI

AR Y

WI

N

DI

NGS

ALT

ERN

AT

OR

R

OT

OR

R

EX

CIT

ER

WI

N

DI

NG

15A

15A

20A

20A

B

B

B

B

B

W

B

R

W

B

B

G

G

G

UPP E R

P

ANE L

GND

S

CRE W

UPPER

P

ANE L

GND

S

CREW

B

R

P

OL

A

RIT

Y

S

WIT

CH

1

4

2

3

214

215

600A

P8-2

600

Y

-T

ER

MI

NAL

R

Y

U

W

-T

ER

MI

NA

L

W

W

W

42

P8-3

42

A

602

P8-4

602

A

U

602

B

203

X

-T

ER

MI

NAL

X

B

n.c.

G

-T

ER

MI

NA

L

G

G

41

A

UPPER

P

ANE L

GND

S

CREW

G

LO

C

AL /

R

EM

OT

E

S

WIT

CH

(SHOWN

IN L

OCAL

PO

SITI

ON)

OPTIONAL REMOTE

CONTROL BOX

TO

D1

AC P OSTS

TO

D1

A

C

PO

ST

D1

D2

-

-

+

+

SHU

NT

FIEL

D

SE

RI

E

SFI

EL

D

BRUS

H

PO

SITI

O

N

SHOW

N

AS

VI

EWE

DF

R

OM

CO

NT

R

OL

PAN

EL

A

1

E

N

N

S

S

N

S

NS

EL

E

CT

ROD

E

WOR

K

2

CR

REEDRELAY

N

U

B

R

P

OL

AR

IT

Y

SW

IT

CH

U

Y

D2

ALT

ERN

AT

OR

R

OT

OR

R

B

201

B

UPP E R

P

ANE L

GND

S

CRE W

D1

W

610

610

600

POWER

SUPPLY

+

15

VDC

608

J

1-

8

E

XC. OV

ER-

VOLTAG

E

PROTECTION

605

J

1-

7

J

1-

3

J

1-

4

600

606

J

2-

3

510

500

J

2-

2

2AMP

PWM

J

1-

1

667

+

14

0VDC

25

V

1/8 AMP

J

1-

5

J

1-

6

J

1-

9

J

1-

2

77

76

75

521

+

14

0VDC

+

15

VDC

J

2-

1

J

2-

5

J

2-

6

501

503

509

IN

P

UT

S

O

UT

P

UT

S

vv

c

v

no

no

no

510

613

n.

c.

S1

A

602

SHUN

TFI

ELD

DRIVE CIR CU

IT

10

K

HOUR

MET

ER

+

_

G

5

B

LOWER

P

ANEL

GND

S

CREW

W

238612

611

PO

SITI

VE

VV

NE

G.

C

V

NE

G.

vv

c

v

567

vv

c

v

GENER

AT

OR

666

622

R1

25,000

uf

75v

x4

C1

C2

C3

C4

621

C

R1

C

OI

L

C

R1

CO

NT

A

CT

S

vv

c

v

GENER

AT

OR

SHU

NT FI

EL

D

30

OHMS

10

0W

602

J

2-

3

TO

P

C

BD

J1-10

229

203

600

A

S1

B

S1

C

50

0OHMS

50

W

50

0OHMS

50

W

S2

AUXILIARYPOWER

CIRCUIT

WE L DC I R C UI T

+

-

+

-

+

-

BOARD

POWER

CR1 CONTAC

TO

R

DR IV ERE T UR N

ARC

V

OLT

AGE

FEEDBACK

WE L DC

OMM

ON

POWER OUTPUT

TO

SHUNT

FI

ELD

CV SW

IT

CH

F

OR

SHUN

TFI

ELD

FL

YWHEEL

DIODE

C

V

ADA

PT

ER

CO

NT

R

OL

PCB

(S

CH

EM. # L6922)

+

-

N

N

A

RM

AT

UR E

&

BRUSHES

-

-

+

+

1

2

3

4

5

6

1

2

3

4

5

6

J

2

8

9

C

V

ADA

PT

ER

CO

NT

R

OL

PCB

TO

D1

AC

PO

ST

R

n.c

.

n.c

.

P

OL

ES

cw

64

o

hms +/- 6. 4,

15

0

W

max

cc

w

64

o

hms +/- 6. 4

15

0W

25

OHM

50

W

x3

12

0OHMS

2.5W

35

A

80

0V

10

0OHMS

50

W

1A

1000

V

max

cc

w

JO

B

S

EL

E

CT

OR

R

HE O

ST

AT

VA

RI

A

BL

E

REA

CT

OR

AUXILIARY OUTPUT

OCV

115/230 VAC+ 10%@ 1800RPM

MAX LOAD 3KW @ 100% D.C.

12

0OHMS

2.5W

1A

1000

V

35

A

80

0V

35

A

80

0V

35

A

80

0V

74

hz

CENTER

OFF

=NOWELDOUTPUT

1

4

2

3

12

.

8m

s

5.

2m

s

0v

50

-2

50

v

MAXP

OT

/NO

L

OAD

0v

50

-2

50

v

12

.

8m

s

.

5m

s

MI

NP

OT

/NO

L

OAD

V

OLT

AG

E

WAV

EF

O

RM : J2-6 to J2-

1IN

C

VM

ODE

36

0-

44

0OHMS@

25

C

23

-2

4vdc

i

nCV

*S EEWAV E

FO

RM

(J

2-

6toJ

2-1)

14

0vdc

(J

2-

3toJ

1-4)

*

14

0vdc

(J

1-

8toJ

1-4)

*

12

.9vdc

(J

1-

5toJ

1-2)

*3. 1v dc

(J

1-

9toJ

1-2)

*N

OT

E:

m

ea

s

ur

em

en

t

m

ad

e

i

nCV

m

od

e.

*0vdc

(J

2-

2toJ

1-4)

14

0vdc ( w/

rh

eo

-statat

m

ax)

14

0vdc

38

.

2-

40

.6

oh

ms

@

25

C

41

.5

oh

ms+/-1 .0@

25

C

MI

N

rh

eo

=

54

vdc

MAX

rh

eo

=

14

0vdc

MI

N

rh

eo

=

86

vac

MAX

rh

eo

=0vac

lo

cat

ed be

hi

nd uppe

r

c

on

t

rol

pane

l

on

re

act

or

bo

x

lo

cat

ed be

hi

nd uppe

r

c

on

t

rol

pane

l

on

re

act

or

bo

x

al

t

er

na

t

or

&

ro

t

or

l

ocat

ed

at

en

dof

gene

ra

t

or

di

od

es

l

ocat

ed be

hi

nd

uppe

rc

on

t

rol

pane

l

lo

cat

ed be

hi

nd uppe

r

c

on

t

rol

pane

l

on

re

act

or

bo

x

lo

cat

ed be

hi

nd uppe

r

c

on

t

rol

pane

l

on

re

act

or

bo

x

lo

cat

ed be

hi

nd

w

or

kst

ud

CV

adap

t

er

bo

x

l

ocat

ed on

l

eftf

ue

l

t

an

k

rai

l

(

vi

ew

ed

f

ro

m

c

on

t

rol

pane

l

en

d)

po

si

ti

ve st

ud

l

ocat

ed on

rig

ht f

ue

l

t

an

k

rai

l

(

vi

ew

ed

f

ro

m

c

on

t

rol

pane

l

en

d)

B

201

201A

CURRENT

SENSE

TO

R

OI

D

ROTOR FIELDAND

FLASHCIRCUIT

WE L DI NG

GENERATOR

2

REM

OT

E

RECE

PT

AC

LE

AND

PL

UG

(SHOWN

IN

NE GA

TIV

E

P

OI

STI

ON)

yw

he

el

di

od

e

F

GENER

AT

O

R

LE

AD

BL

OCK

ou

t

pu

tst

ud

s

l

ocat

ed on

rig

ht f

ue

l

t

an

k

rai

l

(

vi

ew

ed

f

ro

m

c

on

t

rol

pane

l

en

d)

(el

ect

ro

de

cl

osestto c

on

t

rol

pane

l)

D2

610

J

2-

3

+

15

VDC

no

CR1 CONTAC

TO

R

DRIVE CIR CU

IT

J

2-

3

S1

D

C

V

V

OLT

AGE

CO

NT

R

OL

P

OT

CR1 CONTAC

TO

R

DR IV EINP UT

-

+

+

2

9

m

ax

(NOA

FF

EC

T

W/ C V

ADAPT E RHOOKE DUP)

VV

ne

gst

ud

l

ocat

ed on

rig

ht f

ue

l

t

an

k

rai

l

(

vi

ew

ed

f

ro

m

c

on

t

rol

pane

l

en

d)

D2

J

2-

3

-

+

+

9

R3

D2

S AE 400

I

NT ER F ACE WIT H

OPTIONALCVADAPTER

-

+

+

N

OT

E

!!

:WHENINSTA

LL

ING CV ADAPTE R,

"E

LECTROD

E"

STUDBEC

OM

ES VV

"

NE GA

TI

V

E"

STUD,&

"T

OWOR

K"

STUDBEC

OM

ES

"

POS

IT

IV

E"

STUD.

CV

ne

gst

ud

l

ocat

ed on

adap

t

er

bo

x

m

ou

nt

ed on

l

eft

f

ue

l

t

an

k

rai

l

(

vi

ew

ed

f

ro

m

c

on

t

rol

pane

l

en

d)

CVWELD OUTP UT

MIN TO MAXOCV

8-41vdc

WELDRANGE

15-35vdc

MAX LOAD 400A@ 35V @ 60%D.C.

500A@ 35V @35% D. C.

CC WELD OUTPUT

MIN TO MAX OCV57-97VDC @ 1800 RPM

WELD RANGE 80-575 AMPS

MAX LOAD 400A@ 40V @100% D.C.(1725 RPM)

CV MODE

–

POWER UP SEQUENC

E

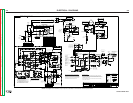

Exciter rotor is flashed from 12v battery supply at

machine power up, exciter winding builds up power.

Exciter windin

g

powers D2 brid

g

e and CR1 contactor

drive circuit on PC board at J1 pins 4 & 8.

CR1 closes, applying pow

er to PC board at J2 pins 2

& 3 and disconnecting flashing circuit.

PC Board PWM circuit regulates output voltage by

using voltage feedback from J1 pin 1 and control pot

at J1 pin 6 to control current thru the shunt fields.

Note!!:

Rheostat

M

ust

be set

to max for CV operation.

V

V MODE

–

POWER UP SEQUENC

E

Exciter rotor is flashed from 12v battery supply at

machine power up, exciter winding builds up power.

CR1 contactor and PC board

DO NOT

power up.

Shunt fields receive power thru PC board.

Rheostat controls current thru the shun

ts.

TO

D1

AC

PO

ST

TO

P8-2

S2

l

ar

ge

s

wi

tch

l

ocat

ed on

face of CV

adap

t

er

bo

x

C

ap

a

ci

t

or

ba

nk

an

d

bl

eede

r

re

si

st

or

l

ocat

ed

i

n

si

de

CV

adap

t

er

bo

x

lo

cat

ed

i

n

si

de

CV

adap

t

er

bo

x

S1s

mall

s

wi

tch

lo

cat

ed on

faceof

CV

adap

t

er

bo

x

CR1

l

ocat

ed

i

n

si

de

CV

adap

t

er

bo

x

TO

P

C

BD

844-TE

RMI

NA

L

LOWER

P

ANEL

GND

S

CREW

t

op

rig

htof

gene

ra

t

or

f

ra

me

lo

cat

ed uppe

rRt

hand

si

de be

hi

nd

c

on

t

rol

pane

l

lo

cat

ed uppe

rLt

hand

si

de be

hi

nd

c

on

t

rol

pane

l

CR1

l

ocat

ed

i

n

si

de

CV

adap

t

er

bo

x

S1s

mall

s

wi

tch

lo

cat

ed on

face of

CV

adap

t

er

bo

x

S1s

mall

s

wi

tch

lo

cat

ed on

faceof

CV

adap

t

er

bo

x

S1s

mall

s

wi

tch

lo

cat

ed on

faceof

CV

adap

t

er

bo

x

lo

cat

ed on

faceof

CV

adap

t

er

bo

x

lo

cat

ed

l

ow

er

c

en

t

er

ofc

on

t

rol

pane

l

lo

cat

ed

l

ow

er

m

iddl

e

of c

on

t

rol

pane

l

OIL

PRESSUR

E

S

WIT

C

H/

SENDER

TEM

PER

AT

UR

E

S

WIT

C

H/

SENDER

IDLER

/

ENGINE PROTECTIONPCBOARD

J31-2

J31-1

J31-3

J31-6

J31-7

J31-8

J31-9

J31-5

J31-

4

RE

D

EN

GI

NE

PR

OT

E

CTI

ON

LIG

HT

J32-1

J32-2

J32-3

J32-4

J31-1

0

ALT

ERN

AT

OR

TY

PI

C

AL

CURRE

NT

DR AW

IS 40

+/- 3 AM

PS

TY

PI

C

AL

CURRE

NT

DR A

W:

3A

+

HOU

RM

ET

ER

TY

PI

C

AL

CURRE

NT

DR A

W:

H

OL

D

C

OIL - 1.1A

P

ULL

C

OIL - 46A

S

WIT

C

H

OPE NS

AT 6

+/-2

P

SI

SENDE

R

OPE R

ATI

O

N:

0P

SI -

> 10+/-5

O

HM

S

40P

SI -

> 105+/-5

O

HM

S

80 P

SI -

> 187+/-5

O

HM

S

SHOW

NI

N

"A

UT

O

IDL

E

"

PO

SITI

ON

SWITC

H

C

LOSES

AT 230

v

+/-

6vF

SE

NDE

R OPE

R

ATION:

140

v

F-

> 134

+/-

13.5 OHMS

194

v

F-

> 51.2

+/-

4.3 OHMS

212

v

F-

> 38.5

+/-

3 OHMS

12 V

OLT -

NO

RM

ALL

Y

OFF

SHOW

NI

N

"

OFF"

PO

SITI

ON

53

50B

51

51A

59

57

212D

212C

43

200

54

44

212A

212B

61

58

58H

238A

844A

-40 TO 40 AM

PS

AMM

ET

E

R

SHOW

SF

ULL

DI

SCHARG

E

W

HIL

E

PRES

SI

NG

GL

O

W

PL

U

G

S

WIT

CH

65AM

P/12

V

OLT

B

+

D+

GL

O

W

PL

UGS

N.C.

N.

O.

EN

GI

NE

SH

UT

DOWN

EN

GI

NE

RUN

NI

NG

C

R1

C

R1

EN

GI

NE

PR

OT

E

CTI

ON

AND

ALT

ERN

AT

OR

FLA

S

HI

NG

D

EL

A

Y TIM

ER

(S

E

E

B

EL

OW

FO

RL

O

GI

C)

IDL

E

R

D

EL

A

Y TIM

E

RCI

R

UIT

S

Q2

O

NF

O

RHI

G

HI

DL

E

INJ

E

CTI

O

N

P

UM

P

S

OL

EN

OI

D

FU

EL

P

UM

P

UNUS ED

US E

DF

O

RT

OR

OI

DI

N

AC

AU

XILI

AR

YM

AC

HI

NE S

P.

C.

B

D. L12400-2

SCH

EM

ATI

C

G4828-2

FLY

BACK

DI

ODE

Q2

IDL

E

S

OL

EN

OI

D

RIGH

T

SI DE

OF

ENGINE

(ASVIEWED

F

R

OM

CONTROLPANE

L)

RI

G

HT

SI

D

E

OF

EN

GI

N

E(

AS

VI

EWE

DF

R

OM

CO

NT

R

OL

PAN

EL)

LOCATED BEHI NDLOWER POR

TI

ON

OF

CONTROLPANEL

SE

NDE

R IS APPRO

X.

500 OHMS AT 70

vF

B2

H

OL

D

C

OIL

P

ULL

C

OIL

B3

55

C

B5

10A

56

B1

212E

844

TO

REEDRELAY

TO

HOUR

M

ET

ER

(+)

238

CENTER

OF

CONTROL

PANEL

CENTER

OF

CONTROL PANEL

RIGH

T

SIDE

OF

ENGINEBY

INJEC

TI

ONPUMP

TY

PI

C

AL

CURRE

NT

DR A

W:

3.3A

RIGH

T

SIDE

OF

ENGINEBY

OI L

F

I

LL

ER

APPRO

XIM

AT

E

RE

SI

ST

ANC

E:

3-4 O

HM

S

APPRO

XIM

AT

E

RE

SI

ST

ANC

E:

3.3 O

HM

S

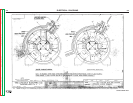

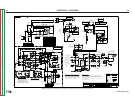

WINDING SPEC'S &RESISTANCES

EXCITER

WINDING

SPEC

RESISTANCE

POWER

ALT-214-3C

.230 OHMS @ 25C

QUADRATURE

ALT-214-3B

.560 OHMS @ 25C

AUXILIARY (TAIL)

ALT-214-3D

.424 OHMS @ 25C

ROTOR (4-POLE)

ALT-214-3A

41.4+/-1.0 OHMS@25C

DIAGRAM M14262

GENERATOR

INTERPOLE

S12261-25

N/A

SHUNT FIELD

FKL-5AJ

19.1-20.3 OHMS @25C

SERIESFIELD

FKL-420-U

N/A

ARMATURE

FKL-37.4N N/A

DIAGRAM

M5570

ST

A

RT

ER

S

OL

EN

OI

D

G

I

S

TEM

PER

AT

UR E

GAUGE

G

I

S

OIL

PRESSURE

GAUGE

IG

NITI

ON

S

WIT

CH

G

W

G

WK

IDL

E

R

S

WIT

CH

GENERATORSHUNT

FIELD CIRCUIT

7

-

+

AMM

ET

ER

LAT

CH

SHOWN FOR REF

ERENCE ONL

Y-

NOT PART OF CV ADA

PTER

UPPER

P

ANE L

GND

S

CRE W

UPP E R

P

ANE L

GND

S

CRE W

GL

O

W

PL

UG

S

WIT

CH

230

V

DUP L E X

RECE

PT

ACL E

115

V

DUP L E X

RECE

PT

ACL E

LE

FT

SIDE

OF

ENGINE

(ASVIEWED

F

R

OM

CONTROLPANE

L)

LOCATED ABOVEENGINE

A

LT

ERNA

TO

R.

RIGH

T

SIDE

OF

ENGINE

(ASVIEWED

F

R

OM

CONTROLPANE

L)

LOCATEDBEHI ND

F

UEL

F

I

LT

ER,

LE

FT

SIDE

OF

ENGINE

(ASVIEWED

F

R

OM

CONTROLPANE

L)

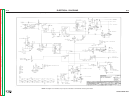

EN

GI

N

E

PR

OT

E

CTI

O

N

AN

D

ALT

ERN

AT

O

RFL

AS

HI

N

G

D

EL

A

Y TIM

E

RL

O

GI

C

UPO

N

RE

CI

EV

EI

N

G

POWE

R,

CI

RC

UIT T

OFL

AS

H

ALT

ERN

AT

O

RI

S

OPENED

AN

D

EN

GI

N

E

PR

OT

E

CTI

O

NI

S

BYPASSE

D.

AFT

E

R TIM

E

D

EL

A

Y,

ALT

ERN

AT

OR

FLA

S

HI

N

G

CI

RC

UIT I

S

CL

OS E

D

AN

D

EN

GI

N

E

PORE

CTI

O

NI

S

ENA

BL

E

D.

N

OT

E:

AFT

E

R TIM

E

D

EL

A

Y

WHE

N

EN

GI

N

E

PR

OT

E

CTI

O

NI

S

ENA

BL

E

D, IF T

H

E

EN

GI

NE

IS

N

OT

ST

A

RT

E

DT

H

E

OIL

PRESSUR

E

WILL

B

EL

O

W

AN

DT

H

EM

AC

HI

N

E

WILL

SH

UT

DOW

N

BECAUS

E

OF T

H

E

EN

GI

N

E

PR

OT

E

CTI

O

NCI

RC

UIT.

IDL

E

S

OL

EN

OI

D CI

RC

UIT L

O

GI

C

1. W

HE

NT

H

E

EN

GI

N

EI

S

RUN

NI

N

GI

NHI

G

HIDL

E

O

R

UNDE

RL

OA

D, T

H

E

S

OL

EN

OI

DI

S

N

OT

ENER

GIZ

E

D.

2. IF N

O

AU

XILI

AR

Y

CURRE

NT

DR A

W

O

R

W

EL

DL

OA

DI

S

SENSE

DF

O

R15

SECOND

S

AN

DT

H

EI

DL

E

R

S

WIT

C

HI

S

O

PE

N(

A

UT

O), T

H

E

P

ULL

AN

D

H

OL

D

C

OIL

OF T

H

EI

DL

E

R

S

OL

EN

OI

D

AR

E

ENER

GIZ

E

D.T

H

E

P

ULL

C

OIL I

S

D

E-

ENER

GIZ

E

D

AFT

E

R

H

ALF

A

SECON

D.

3.

IF

AN AUXILIARY CUR

RENT D

RA

W OR

W

ELD LOAD IS SENS

ED OR THE IDLER S

WITCH IS CLOSE

D (HIGH)

,

THE

IDLE SOLEN

OID IS

DE-ENER

GIZED.

B

lo

cat

ed gene

ra

t

or

en

dof

m

ac

hi

ne

lo

cat

ed en

gi

ne

rig

ht

si

de

(

vi

ew f

ro

m

c

on

t

rol

pane

l

en

d)

FRAME

FRAME

ENGINE B

LO

CK

+

+

E

N

GI

NE

ST

AR

TE

R

12 V

OLT

B

ATT

ERY

235

ST

A

RT

S

WIT

CH

50A

INJ

E

CTI

O

N

P

UM

P

TIMIN

G

S

OL

EN

OI

D

EN

GI

NE

TEM

PER

AT

UR E

SENSOR

212F

16 O

HM

S

0.9 AM

PS

RI

G

HT

SI

D

E

OF

EN

GI

NE

O

NI

NJ

E

CTI

O

N

P

UM

P

INJ

E

CTI

O

N

P

UM

P TIMI

NG

S

OL

EN

OI

DT

Y

P.

CURRE

NT

DR A

W 0.9

A

APPRO

X.

RE

SI

ST

ANC

E 16

O

HM

S

MA

Y

NOT APPEAR ON

ALL MODELS

212F

810

7A

C

B4

4A

C

B3

C

B1

11A

11

400F

11B

6A

202

B

203A

602C

22

G-8

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC