TROUBLESHOOTING & REPAIR

F-60 F-60

COMMANDER 300

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CURRENT BALANCE TEST (continued)

TEST PROCEDURE

1. Turn the engine off.

2. Perform the Case Cover Removal

Procedure and tilt the control panel out.

3. Locate plug J3 at the control board and P15

in the main harness. See Figure F.29.

4. Disconnect P15.

ELECTRIC SHOCK CAN KILL.

• Do not touch electrically

live parts such as output

terminals or internal wiring.

• Insulate yourself from the

work and ground.

• Always wear dry insulating

gloves.

5. Start the machine.

6. In CC mode, load the machine on a load grid

to 375 amps at 34 VDC.

7. Immediately after applying the load, use a

voltmeter to measure (one at a time) the volt-

age from each chopper heat sink to the posi-

tive weld stud. Each voltage measurement

should be .75-1.3 VDC and both measure-

ments must be within .1VDC of each other.

8. A voltage out of spec indicates a possible

blown IGBT chopper module and the chopper

boards must be replaced. Replace both chop-

per boards using the POWER MODULE

(CHOPPER) PC BOARD REMOVAL AND

REPLACEMENT PROCEDURE.

9. A voltage within spec indicates that the chop-

per modules are sharing weld current relative-

ly equal and the chopper boards are ok.

10. Remove the load and turn off the engine.

11. Disconnect J3 at the control board. See

Figure F.29.

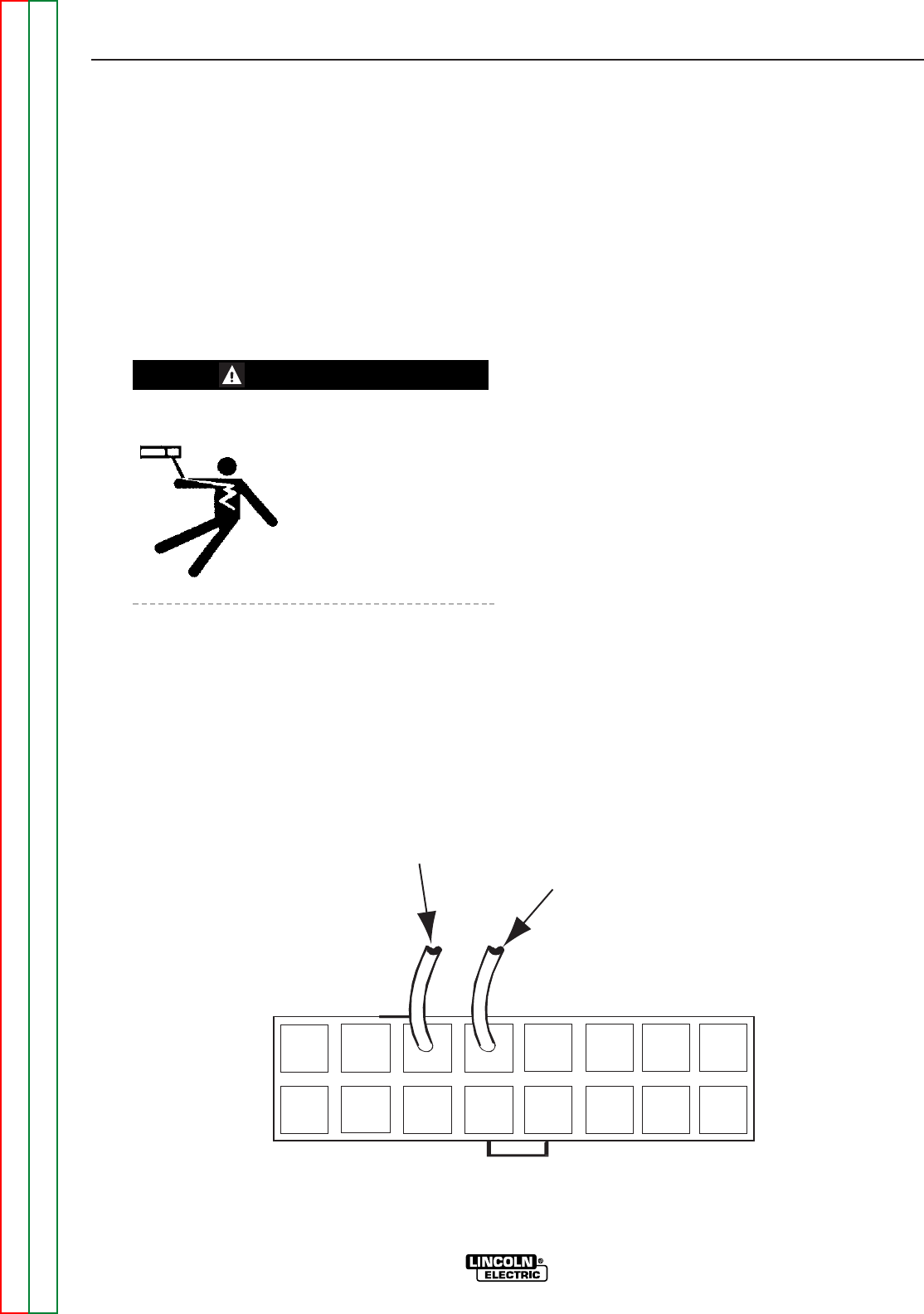

12. Using a pair of wire cutters, cut leads 68 and

69 from the #3 and #4 cavities of plug J3.

Butt tape and insulate loose ends. See

Figure F.28.

NOTE: Cutting and removing these leads will

help to eliminate intermittent lack of out-

put problems.

13. Plug J3 back into the control board.

14. Using the CASE COVER REMOVAL AND

REPLACEMENT PROCEDURE, install the

control panel and side panels on the

machine.

69

68

Plug J3

FIGURE - F.28 PLUG J3

WARNING