CHOPPER TECHNOLOGY

FUNDAMENTALS

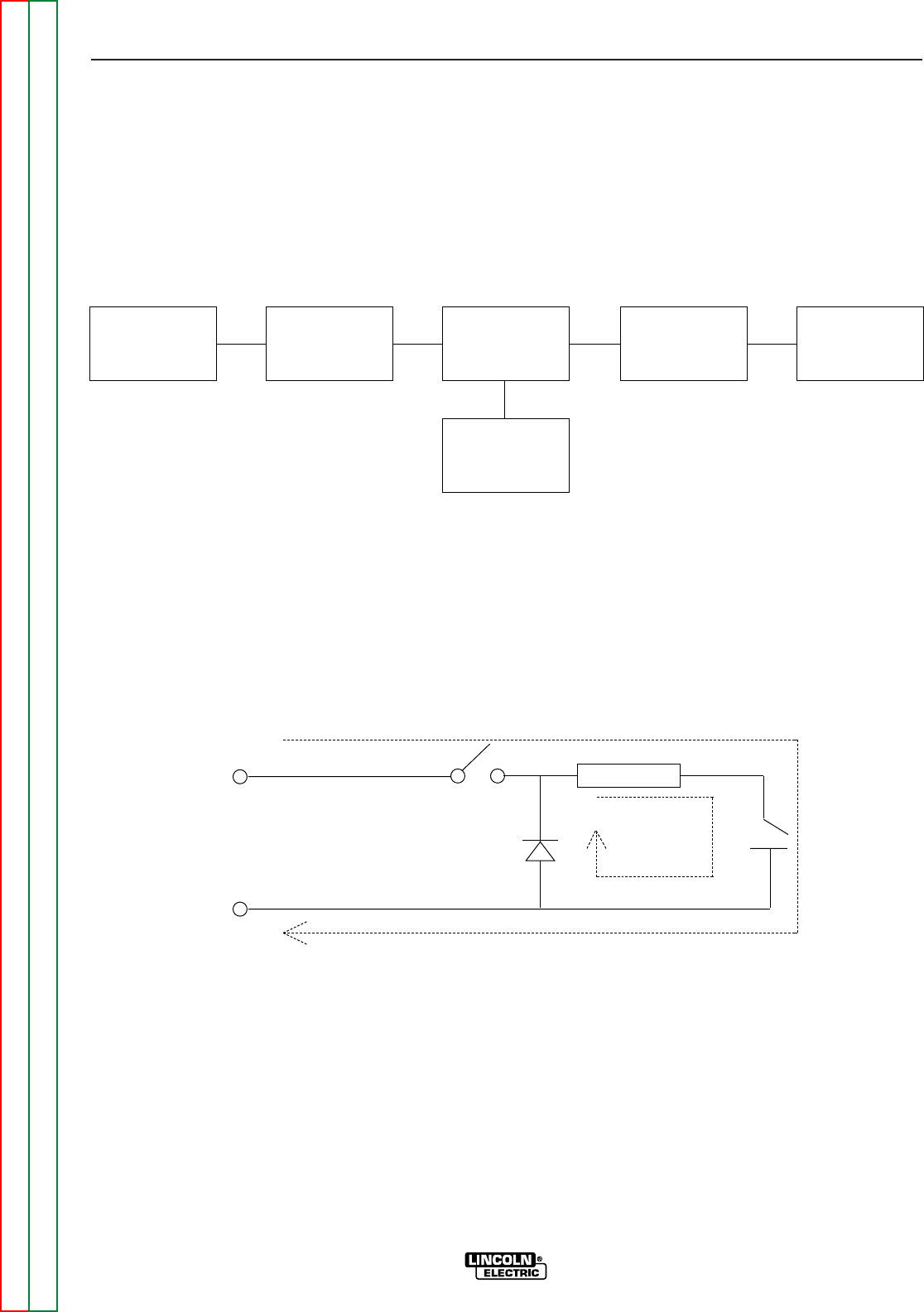

The new era of welding machines such as the

Commander 300, employ a technology whereby a DC

source is turned on and off (chopped up) at high speed,

then smoothed through an inductor to control an arc.

Hence the name “Chopper.” The biggest advantage of

the chopper technology is the high-speed control of the

arc, similar to the inverter machines. A block diagram

for this is as follows:

In this system, the engine drives a three-phase alter-

nator, which generates power that is rectified and fil-

tered to produce about 85VDC. The current is

applied through a solid state switch to an inductor. By

turning

the switch on and off, current in the inductor and the

arc can be controlled. The following diagram depicts

the current flow in the system when the switch is open

and closed:

When the switch is closed, current is applied through

the inductor to the arc. When the switch opens, current

stored in the inductor sustains flow in the arc and

through the diode. The repetition rate of switch closure

is 20Khz, which allows ultra-fast control of the arc. By

varying the ratio of on time versus off time of the switch

(Duty Cycle), the current applied to the arc is con-

trolled. This is the basis for Chopper Technology:

Controlling the switch in such a way as to produce

superior welding.

THEORY OF OPERATION

E-7 E-7

COMMANDER 300

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

3 PHASE

ALTERNATOR

DC RECTIFIER

AND FILTER

INDUCTOR

AND DIODE

ARC

ARC

CONTROL

SOLID STATE

SWITCH

INDUCTOR

SWITCH

DIODE

ARC

CURRENT WITH SWITCH OPEN

CURRENT WITH SWITCH CLOSED

85VDC