K-1

E6581301

11

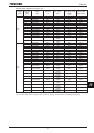

11. Table of parameters

1. User parameter *3 Sensorless vector/vector with sensor (Ɣ:Effective, -:Ineffective)

Title

Communi

cation

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

Default

setting

Write during

running

Vector contro

l

PM

control

*2

V/f

*1

Reference

Speed

control

Torque

control

HE -

Operation

frequency of

operation panel

NN~HJ Hz 0.1/0.01 0 Enabled Ɣ/Ɣ Ɣ/Ɣ Ɣ Ɣ 3. 2

*1: V/f : Any setting of RV=,,*2: PM control : RV= setting *3: Sensorless vector : Any setting of RV=,, / Vector with sensor : Any setting of RV=,

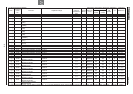

2. Basic parameter [1/4] Sensorless vector/vector with sensor (Ɣ:Effective, -:Ineffective)

Title

Communi

cation

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

Default

setting

Write during

running

Vector control

PM

control

V/f

Reference

Speed

control

Torque

control

CWJ

-

History function

1/1

-

-

Ɣ

/

Ɣ

Ɣ

/

Ɣ

Ɣ

Ɣ

5. 1

CW

0000

Automatic

acceleration/deceleration

0:Disabled

1:Automatic setting

2:Automatic setting (during acceleration only)

1/1 0 Disabled Ɣ/Ɣ - Ɣ Ɣ 5. 2

CW

0001 Automatic torque boost

0:Disabled

1:Automatic torque boost + auto-tuning 1

2:

Sensorless vector control 1

+ auto

-

tuning

1

1/1 0 Disabled Ɣ/Ɣ - Ɣ Ɣ 5. 3

CW

0040

Automatic function

setting

0:Disabled

1:Frequency setting by means of voltage

2:Frequency setting by means of current

3:Voltage/current switching from external terminal

4: Frequency setting on operation panel and operation by

means of terminals

5: Frequency setting and operation on operation panel

1/1 0 Disabled Ɣ/Ɣ Ɣ/Ɣ Ɣ Ɣ 5. 4

EOQF

0003

Command mode

selection

0:Terminal input enabled

1:Operation panel input enabled (including LED/LCD

option input)

2:2-wire RS485 communication input

3:4-wireRS485 communication input

4:Communication option input

1/1 0 Disabled Ɣ/Ɣ Ɣ/Ɣ Ɣ Ɣ 5. 5

HOQF

0004

Frequency setting mode

selection 1

1:VI/II (voltage/current input)

2:RR/S4 (potentiometer/voltage input)

3:RX (voltage input)

4:Operation panel input enabled (including LED/LCD

option input)

5:2-wire RS485 communication input

6:4-wire RS485 communication input

7:Communication option input

8:Optional AI1 (differential current input)

9:Optional AI2 (voltage/current input)

10:Motor operated pot mop setting

11:Optional RP pulse input

12:Optional high-speed pulse input

13:

-

(

Unsupporte

d option

)

1/1 2 Disabled Ɣ/Ɣ - Ɣ Ɣ 5. 5