E6581301

E-10

5

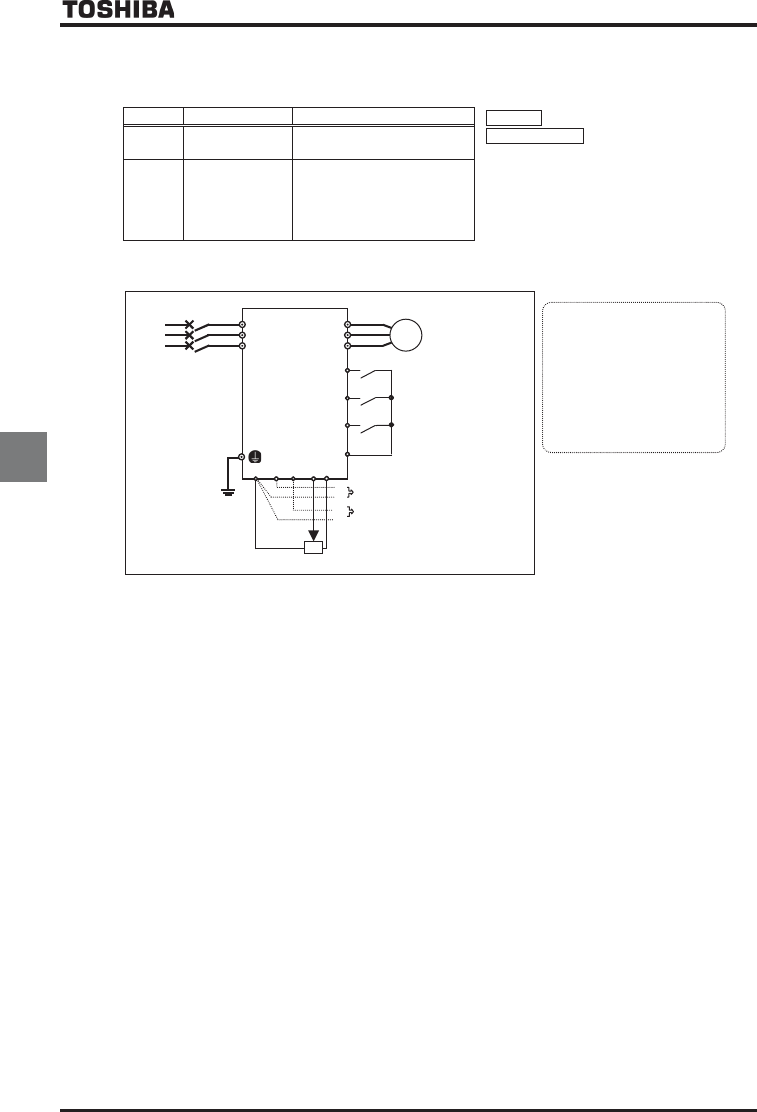

4) Setting the run, stop and operation frequencies (forward run, reverse

run and coast stop) by means of external signals (default setting)

Title Function Example of setting

Run/stop :ON/OFF of terminals F-CC/R-CC

Speed command :External signal input

(1) VI/II terminal: 0~+10Vdc

(0~+5Vdc) or

4(0)~20mAdc

(2) RR/S4 terminal: Potentiometer

0~+10Vdc (0~+5Vdc)

(3) RX terminal: 0~±10Vdc (0~±5Vdc)

EOQF

Command mode

selection

:(Terminal input)

HOQF

Frequency

setting mode

selection 1

(VI/II (voltage/current input) )

(RR/S4

(potentiometer/voltage

input) )

(RX (voltage input) )

Motor

IM

R/L1

Power

supply

S/L2

T/L3

U/T1

V/T2

W/T3

(1) 0~+10Vdc

(0~+5Vdc)

or 4(0)~20mAdc

(3) 0~±10Vdc

(0~±5Vdc)

(2) External potentiometer

-

-

+

+

F

R

ST

CC

ON:Forward run,

OFF:Deceleration stop

ON:Reverse run,

OFF:Deceleration stop

ON:Standby,

OFF:Coast stop

* Other speed setting

: 2-wire RS485 input

: 4-wire RS485 input enabled

: Communication option input enabled

*

:

Optional

AI1 (Differential current

input)

*

:

Optional

AI2 (voltage/current input)

*

:

Motor operated pot mop setting

: RP pulse input

*

: High-speed pulse input

*

: -

* Commands marked with * are

optional. Refer to Instruction Manual

of options described in Section 10.

CCA RX

VI/II

RR/S4

PP

Inverter

Ŭ

The inverter is

factory-

configured so that,

if F and R are turned on at

the same time, the

inverter will stop

operation. If necessary,

the direction of rotation

can be reversed by

changing parameter

settings.

Refer to Section 6.2.

1

.

«

Example of a connection diagram: SW1 set to sink logic

»