X-STREAM

4-31

Instruction Manual

HASAxE-IM-HS

07/2006

Emerson Process Management GmbH & Co. OHG

4 Installation

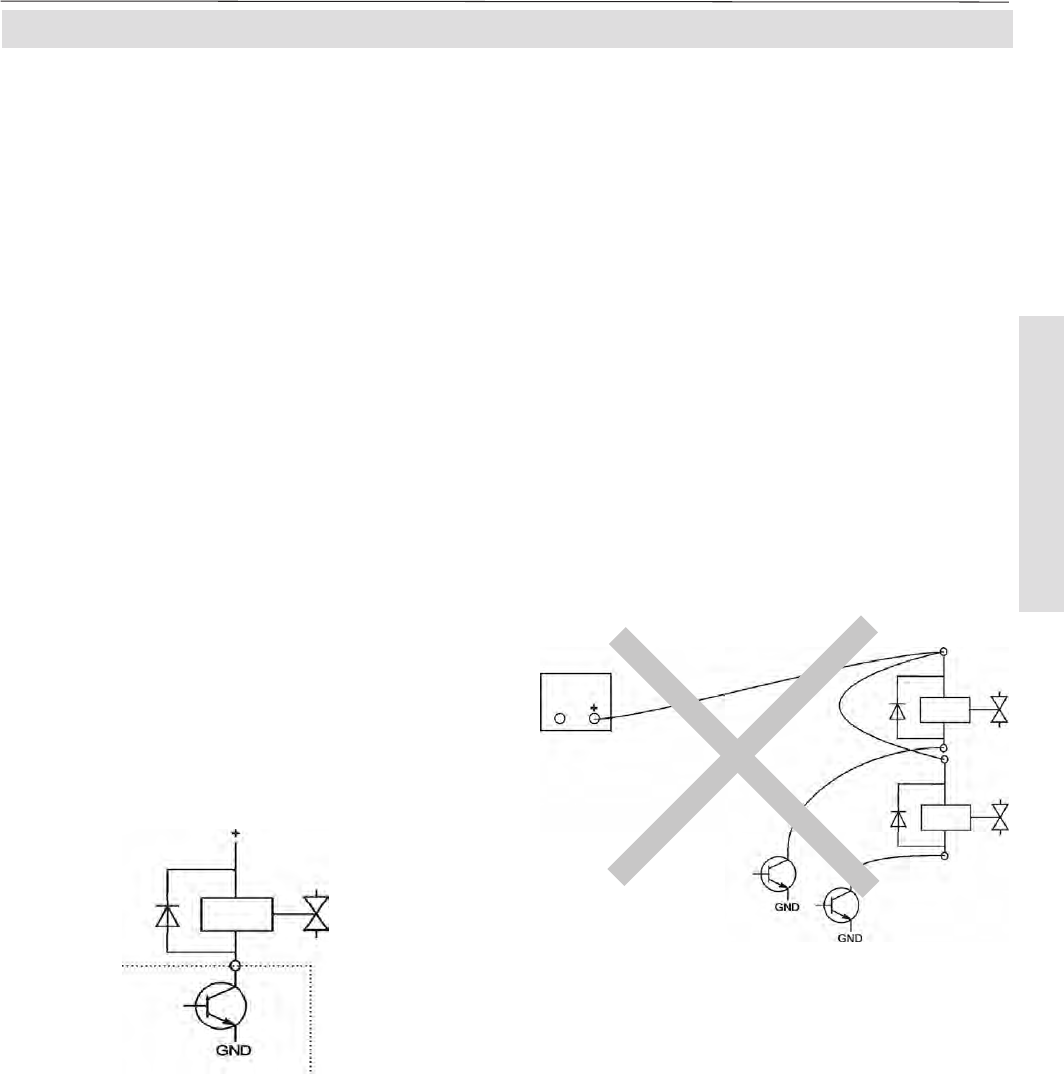

4-5-2 Wiring Inductive Loads

Switching inductive loads is a standard

application generating electromagnetic

disturbances:

The moment an inductive load (e.g. relay, valve,

etc.) is switched off, it‘s magnetic field defies

the change of current flow, generating high

voltages (up to hundrets of volts) at the coil‘s

contacts. This impulse reproduces on

connected wires and may influence electrical

equipment nearby or destroy signal inputs and/

or outputs on electronic boards.

A simple measure helps to avoid such effects:

• Shunt a silicon diode to the inductive load‘s

contacts shorting the voltage impulse just

at it‘s source.

The diode‘s cathode needs to be

connected to the positive side of the coil,

the anode to the negative side (fig. 4-28).

Suitable filter components are available on

request for standard valves.

Fig. 4-28: Suppressor Diode

for Inductive Loads

Another popular application is driving multiple

loads within one system by multiple outputs,

whereat the supply voltage for the loads is taken

from one common source.

To minimize load switching generated

disturbances special care is required when

wiring the system:

• AVOID to "serial" wire the loads‘ power

supplies with the power supply line starting

at the source and successively connecting

all loads (fig. 4-29):

4-5-3 Driving Multiple Loads

Fig. 4-29: ”Serial” Wiring

4-5 Installation - Hints on Wiring