X-STREAM

Emerson Process Management GmbH & Co. OHG 7-11

Instruction Manual

HASAxE-IM-HS

05/2006

7 Maintenance

As described earlier, advanced calibration is

possible only with installed internal and/or

external valves.

In addition this requires all requested cali-

bration gases to be connected to the valves

and the valves to be software assigned to the

gases.

Why is assigning valves required?

For advanced calibrations the analyzer controls

the gas flow without operator interaction and

therefore needs to "know" about the different

valve functions - this is done by valve

assignment.

In addition variable valve assignment allows to

use one valve for different functions.

Example:

• Dual channel analyzer for measuring CO

and CO

2

.

• Spangases are CO and CO

2

, zero gas

for both channels is N

2

.

Without variable assignment one would need

to zero span channel 1 separately from channel

2. Taking into account the purges times before

a calibration calculation starts, to ensure the

measuring cells are filled with calibration gas,

the whole procedure would take a quite long

time.

With variable valve assignment the operator

can specify e.g. the valve V1 to be the zero

gas valve for channel 1 AND channel 2. Now,

when starting a zero calibration, the analyzer

calculates the zero values for both channels

at a time!

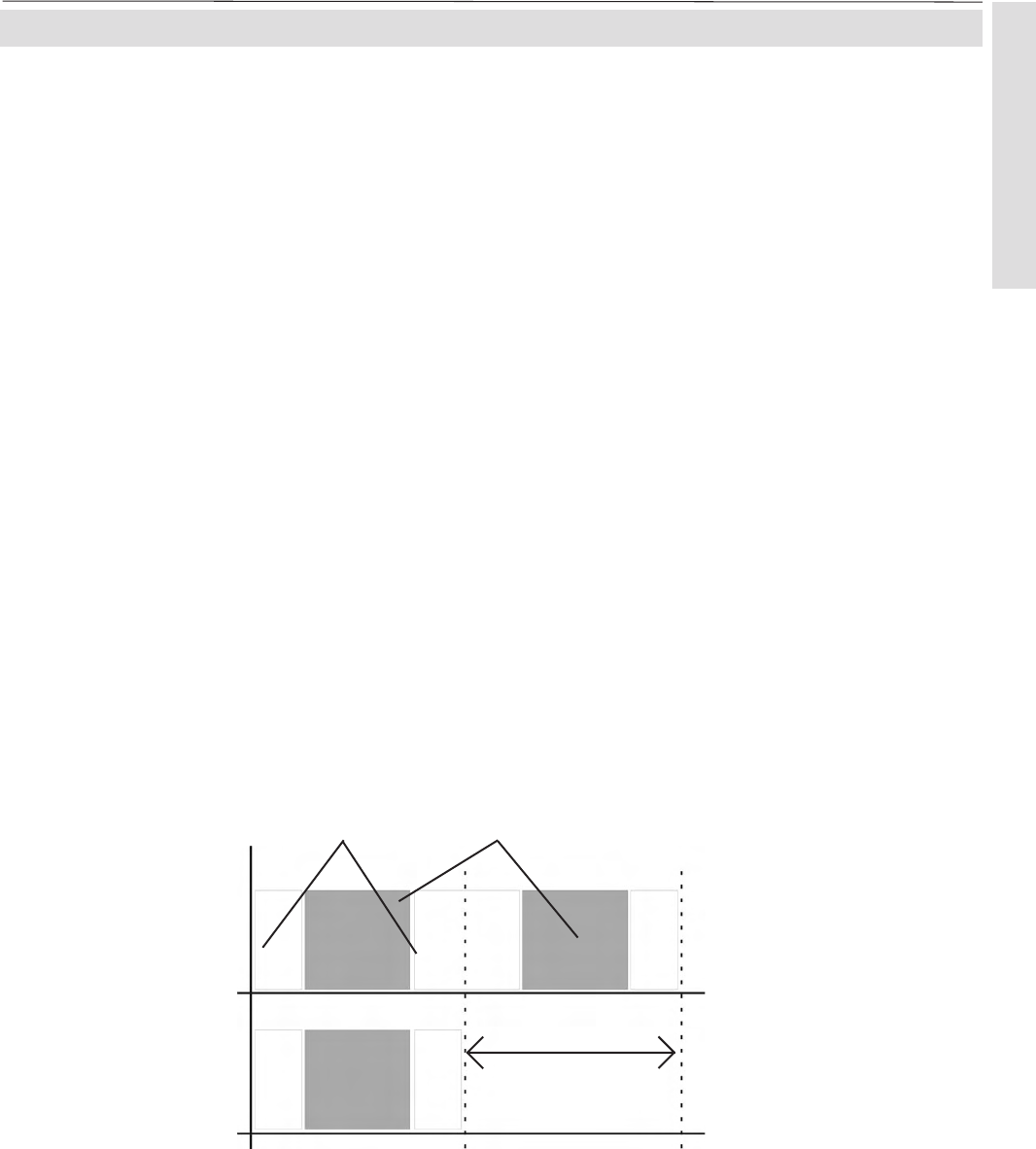

Zero spanning with

fixed assignment

Zero spanning with

variable assignment

purge times

calibration

ch 1 ch 1 ch 1 ch 2 ch 2 ch 2

ch 1

&

ch2

ch 1

&

ch2

ch 1

&

ch2

improvement in

time

timeline

Fig. 7-2: Calibration improvement by variable valve assignments

7-3-3-1 Additional Preparations for

Advanced Calibration

7-3-3 Advanced Calibration