X-STREAM

3-3

Instruction Manual

HASAxE-IM-HS

05/2006

Emerson Process Management GmbH & Co. OHG

3 Principles

3-1-2 Opto Pneumatic Measuring Principle

This high performance principle is used for IR

and UV measurements and utilizes a separated

analysis cell whose one side is passed by the

sample gas. The other side (reference side) is

either filled with an inert gas (e.g. nitrogen) or

passed by a reference gas stream, depending

on application.

Both sides of the cell are alternately irradiated

with IR (UV) light of same intensity, which

afterwards passes a filtering cell before it

arrives at the detector.

The opto pneumatical detector, which is used

instead of the pyroelectrical detector with the

IFC principle, converts the radiation from sam-

ple side and reference side into a voltage

signal proportional to the radiation intensity.

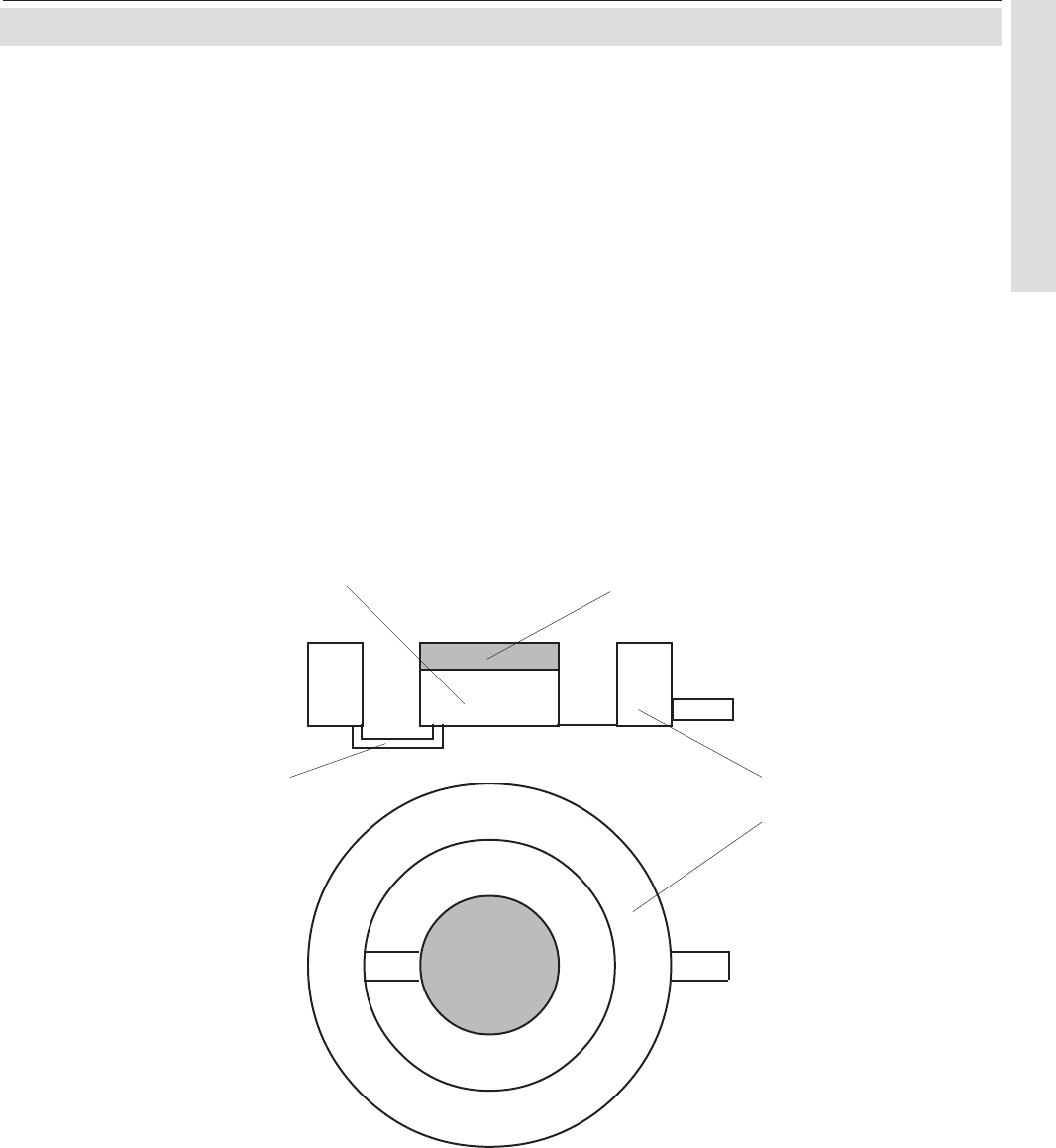

The pneumatical detector consists of a gas

filled absorption chamber and a compensation

chamber, both connected by a flow channel. A

micro flow detector is placed within this channel

to measure least flows.

compensation chamber

Fig. 3-2: Gas Detector Design Principle

gas filler

absorption chamber

flow channel

with

micro flow detector

CaF

2

window

3-1 Infrared (IR) and Ultraviolet (UV) Measurement