X-STREAM

Emerson Process Management GmbH & Co. OHG7-2

Instruction Manual

HASAxE-IM-HS

05/2006

7-2 Performing a Leak Test

To achieve best and proper measuring results

you must ensure the gas path system does not

have leaks.

The following procedure describes how to per-

form a leak test with focus on the instrument.

The gas path system should be leak tested at

least on a bimonthly basis and after

maintenance, replacement or repair of gas

path parts.

Note!

It is recommended to include external

equipment (e.g. cooler, dust filters, etc.) into

a leak test!

7-2 Performing a Leak Test

Required tools

• U-turn manometer for max. 7.25 psi

(500 mbar)

• Stop valve

Procedure

• Connect the water filled u-turn manometer

to the analyzer‘s sample gas output

(disconnect external gas lines).

• Install the stop valve between gas input

fitting and a Nitrogen (N

2

) supply.

• Open the stop valve until the internal gas

path is under pressure of approx. 0.725

psi/50 mbar (corresponding to 19.7 inch/

500 mm water column)

• Close the stop valve. After a short time for

the water to balance the water level must

not change over a time period of approx.

5 minutes!

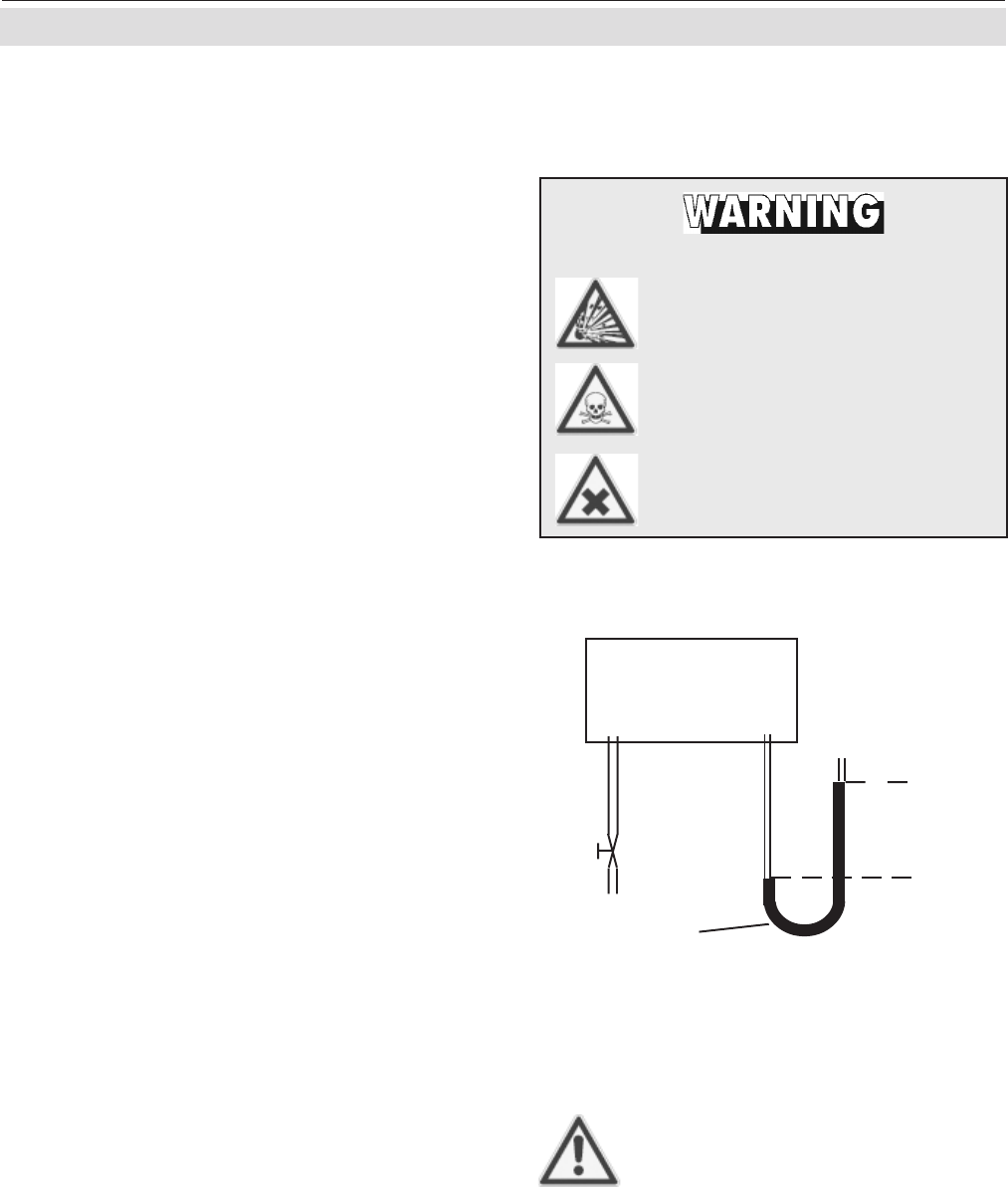

HAZARD FROM GASES !

Before opening gas paths they

must be purged with ambient

air or neutral gas (N

2

) to avoid

hazards caused by toxic, flam-

mable, explosive or harmful to

health sample gas compo-

nents!

Analyzer

overpressure

approx.

0.725 psi/50 mbar

stop

valve

Water

Fig. 7-1: Leak Testing with

U-turn Manometer

Max. pressure 7.25 psig (500 mbar)!

Dual channel instruments:

Analyzers with parallel tubing

require separate leak tests for

each gas path !