SJ300 Inverter

Operations

and Monitoring

4–7

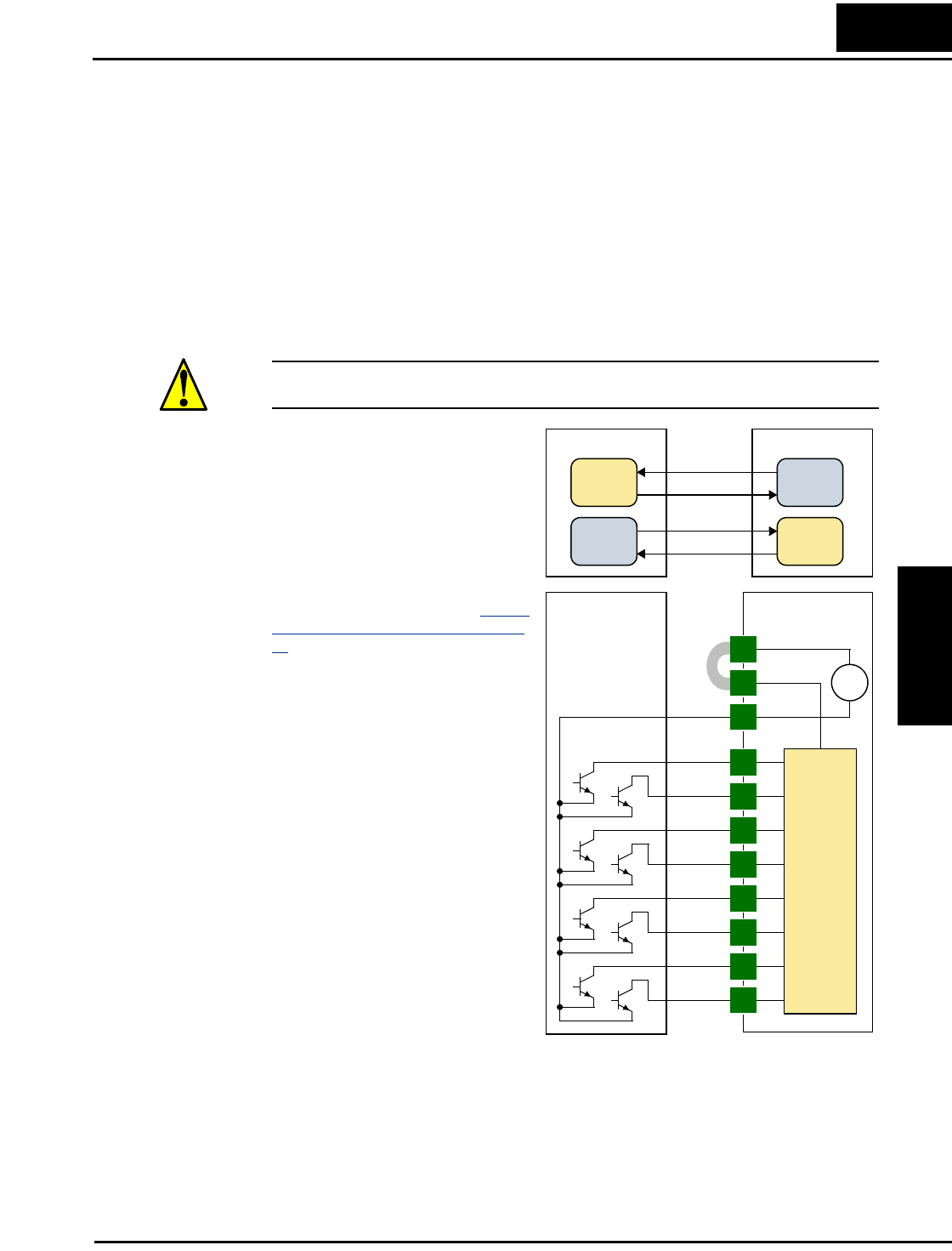

Connecting to PLCs and Other Devices

Hitachi inverters (drives) are useful in many types of applications. During installation, the

inverter keypad (or other programming device) will facilitate the initial configuration. After

installation, the inverter will generally receive its control commands through the control logic

terminals or serial interface from another controlling device. In a simple application such as

single-conveyor speed control, a Run/Stop switch and potentiometer will give the operator all

the required control. In a sophisticated application, you may have a programmable logic

controller (PLC) as the system controller with several connections to the inverter.

It is not possible to cover all the possible types of application in this manual. It will be neces-

sary for you to know the electrical characteristics of the devices you want to connect to the

inverter. Then, this section and the following sections on I/O terminal functions can help you

quickly and safely connect those devices to the inverter.

CAUTION: It is possible to damage the inverter or other devices if your application exceeds

the maximum current or voltage characteristics of a connection point.

The connections between the inverter

and other devices rely on the electrical

input/output characteristics at both ends

of each connection, shown in the

diagram to the right. The inverter can

accept either sourcing or sinking type

inputs from an external device (such as

a PLC). A terminal jumper configures

the input type, connecting the input

circuit common to the supply (+) or (–).

Detailed wiring examples are in “

Using

Intelligent Input Terminals” on page 4–

11. This chapter shows the inverter’s

internal electrical component(s) at each

I/O terminal and how to interface them

with external circuits.

In order to avoid equipment damage and

get your application running smoothly,

we recommend drawing a schematic of

each connection between the inverter

and the other device. Include the

internal components of each device in

the schematic, so that it makes a

complete circuit loop.

After making the schematic, then:

1. Verify that the current and voltage

for each connection is within the

operating limits of each device.

2. Make sure that the logic sense

(active high or active low) of any

ON/OFF connection is correct.

3. Verify inputs are configured

correctly (sink/source) to interface

to interface to any external devices (PLCs, etc.).

4. Check the zero and span (curve end points) for analog connections, and be sure the scale

factor from input to output is correct.

5. Understand what will happen at the system level if any particular device suddenly loses

power, or powers up after other devices.

5

3

1

7

6

4

2

8

Other device

Input

circuit

Output

circuit

SJ300 Inverter

Input

circuit

Output

circuit

Input

circuits

Inverter

Common

PLC

PLC

P24

CM1

+

–

24VDC

Jumper

Signal

Return

Signal

Return