Introduction to Variable-Frequency Drives

Geting Started

1–16

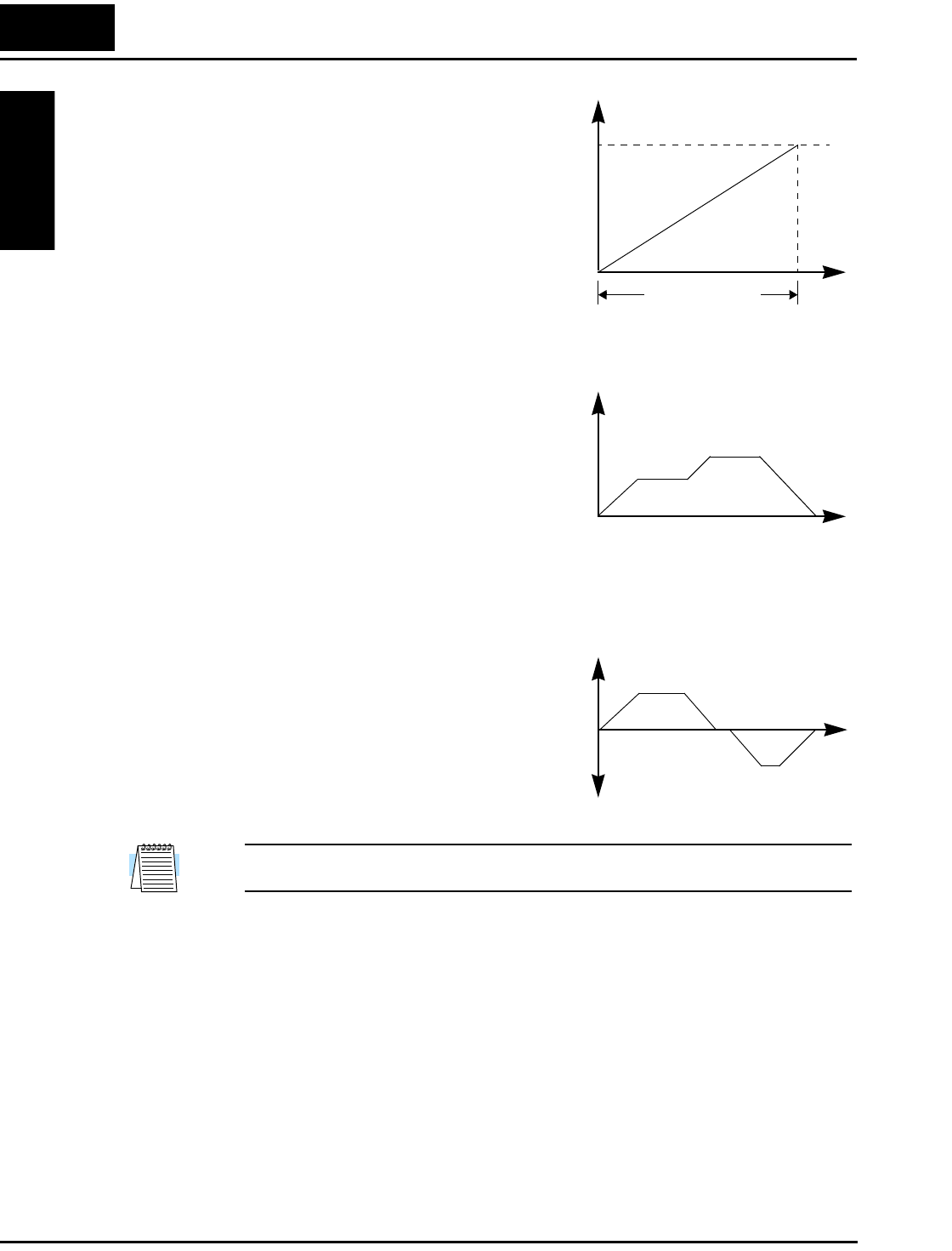

Acceleration and deceleration settings

specify the time required to go from a stop to

maximum frequency (or visa versa). The

resulting slope (speed change divided by

time) is the acceleration or deceleration. An

increase in output frequency uses the accel-

eration slope, while a decrease uses the

deceleration slope. The accel or decel time a

particular speed change depends on the

starting and ending frequencies. However,

the slope is constant, corresponding to the

full-scale accel or decel time setting.

For example, the full-scale acceleration

setting (time) may be 10 seconds—the time

required to go from 0 to 60 Hz.

The SJ300 inverter can store up to 16 preset

speeds. And, it can apply separate accelera-

tion and deceleration transitions from any

preset to any other preset speed. A multi-

speed profile (shown at right) uses two or

more preset speeds, which you can select via

intelligent input terminals. This external

control can apply any preset speed at any

time. Alternatively, the selected speed is

infinitely variable across the speed range.

You can use the potentiometer control on the

keypad for manual control. The drive

accepts analog 0-10V signals and 4-20 mA

control signals as well.

The inverter can drive the motor in either

direction. Separate FW and RV commands

select the direction of rotation. The motion

profile example shows a forward motion

followed by a reverse motion of shorter

duration. The speed presets and analog

signals control the magnitude of the speed,

while the FW and RV commands determine

the direction before the motion starts.

NOTE: The SJ300 can move loads in both directions. However, it is not designed for use in

servo-type applications that use a bipolar velocity signal that determines direction.

Speed

Maximum speed

0

Acceleration

t

Acceleration (time) setting

Speed

Speed 1

Speed 2

t

Multi-speed Profile

Speed

Forward move

Reverse move

t

Bi-directional Profile