Connecting to PLCs and Other Devices

Operations

and Monitoring

4–8

Example Wiring

Diagram

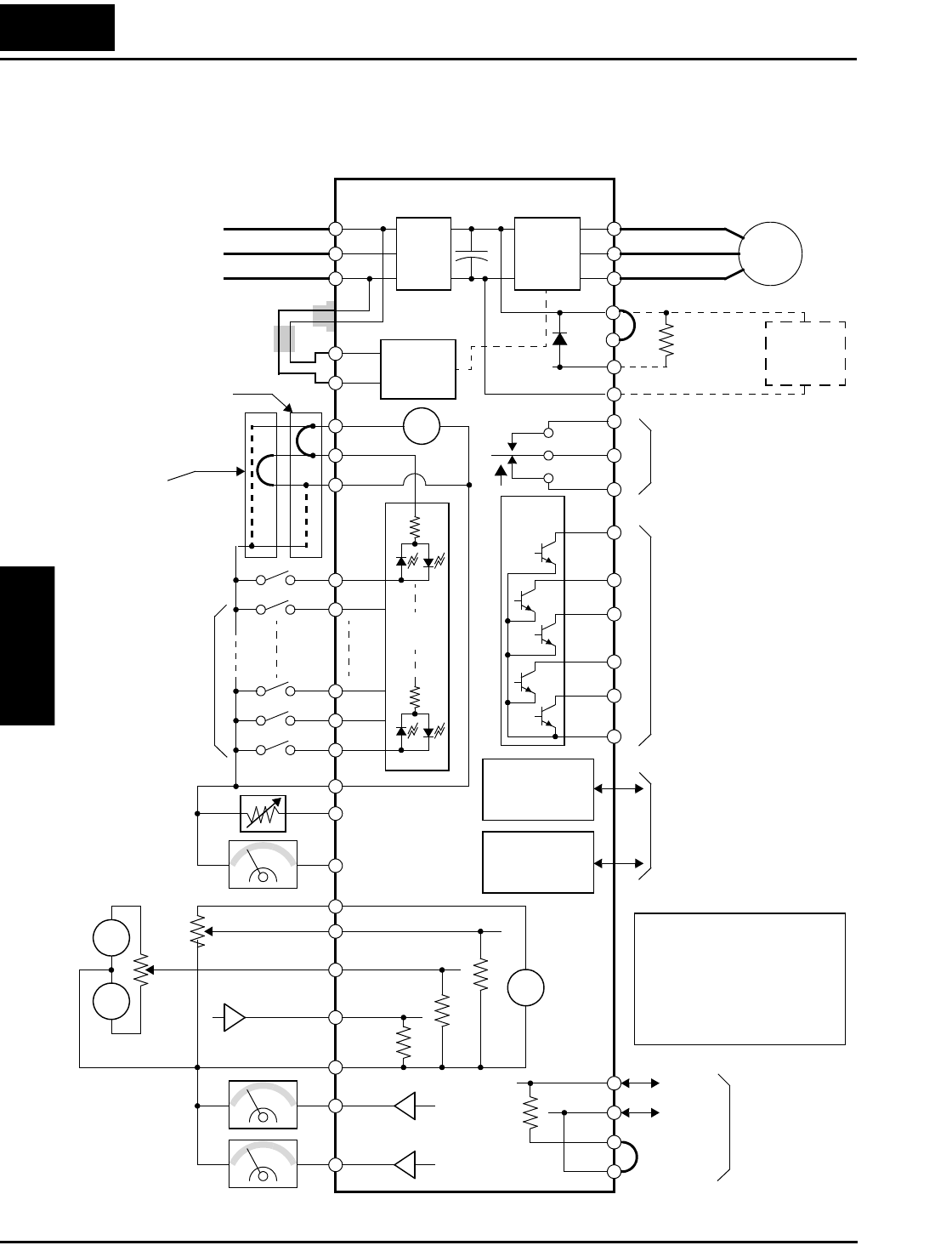

The schematic diagram below provides a general example of logic connector wiring, in

addition to basic power and motor wiring covered in Chapter 2. The goal of this chapter is to

help you determine the proper connections for the various terminals shown below for your

specific application needs.

U

V

W

Motor

R

S

T

Expansion

Card #1

(optional)

Expansion

Card #2

(optional)

T

R

R0

T0

Power source,

3-phase

P24

PLC

FW

8

3

2

1

Forward

Reverse

Intelligent inputs,

8 terminals

CM1

24VDC

TH

FM output

monitor

Thermistor

H

O

O2

OI

L

AM

AMI

4 – 20mA

Analog GND

+

–

+

–

-10 / 0 / +10 VDC

0 – 10VDC

+

–

+10VDC

reference

250Ω

10kΩ

10kΩ

+10VDC reference

P

PD

RB

N

Braking

resistor

(optional)

SP

SN

RP

SN

RS-485 serial

communications

Jumper for

termination

Send/

receive

100Ω

Intelligent relay output

(alarm function default)

Signals for expanded

features, including

encoder feedback,

digital I/O, and

DeviceNet networking

Intelligent outputs,

5 terminals,

open-collector

CM2

11

12

13

14

15

Input

circuits

Output

circuits

FM

Braking

unit

(optional)

AM output

monitor

AMI output

monitor

Control

circuit

Recti-

fier

InverterConverter

DC bus

+

–

+

–

2-wire jumper

J51

Ferrite filter

SJ300

AL0

AL2

AL1

NOTE: For the wiring of intel-

ligent I/O and analog inputs,

be sure to use twisted pair /

shielded cable. Attach the

shield wire for each signal to

its respective common termi-

nal at the inverter end only.

+

–

CM1

Default jumper position

for –xFU/–xFR models

(sourcing type inputs)

Default jumper position

for –xFE models

(sinking type inputs)

L1

L2

L3

T1

T2

T3