Using Intelligent Input Terminals

Operations

and Monitoring

4–30

PID ON/OFF

and PID Clear

The PID loop function is useful for controlling motor speed to achieve constant flow, pressure,

temperature, etc. in many process applications. The PID Disable function temporarily suspends

PID loop execution via an intelligent input terminal. It overrides the parameter A071 (PID

Enable) to stop PID execution and return to normal motor frequency output characteristics. the

use of PID Disable on an intelligent input terminal is optional. Of course, any use of the PID

loop control requires setting PID Enable function A071=01.

The PID Clear function forces the PID loop integrator sum = 0. So, when you turn ON an intel-

ligent input configured as [PIDC], the integrator sum is reset to zero. This is useful when

switching from manual control to PID loop control and the motor is stopped.

CAUTION: Be careful not to turn PID Clear ON and reset the integrator sum when the inverter

is in Run Mode (output to motor is ON). Otherwise, this could cause the motor to decelerate

rapidly, resulting in a trip.

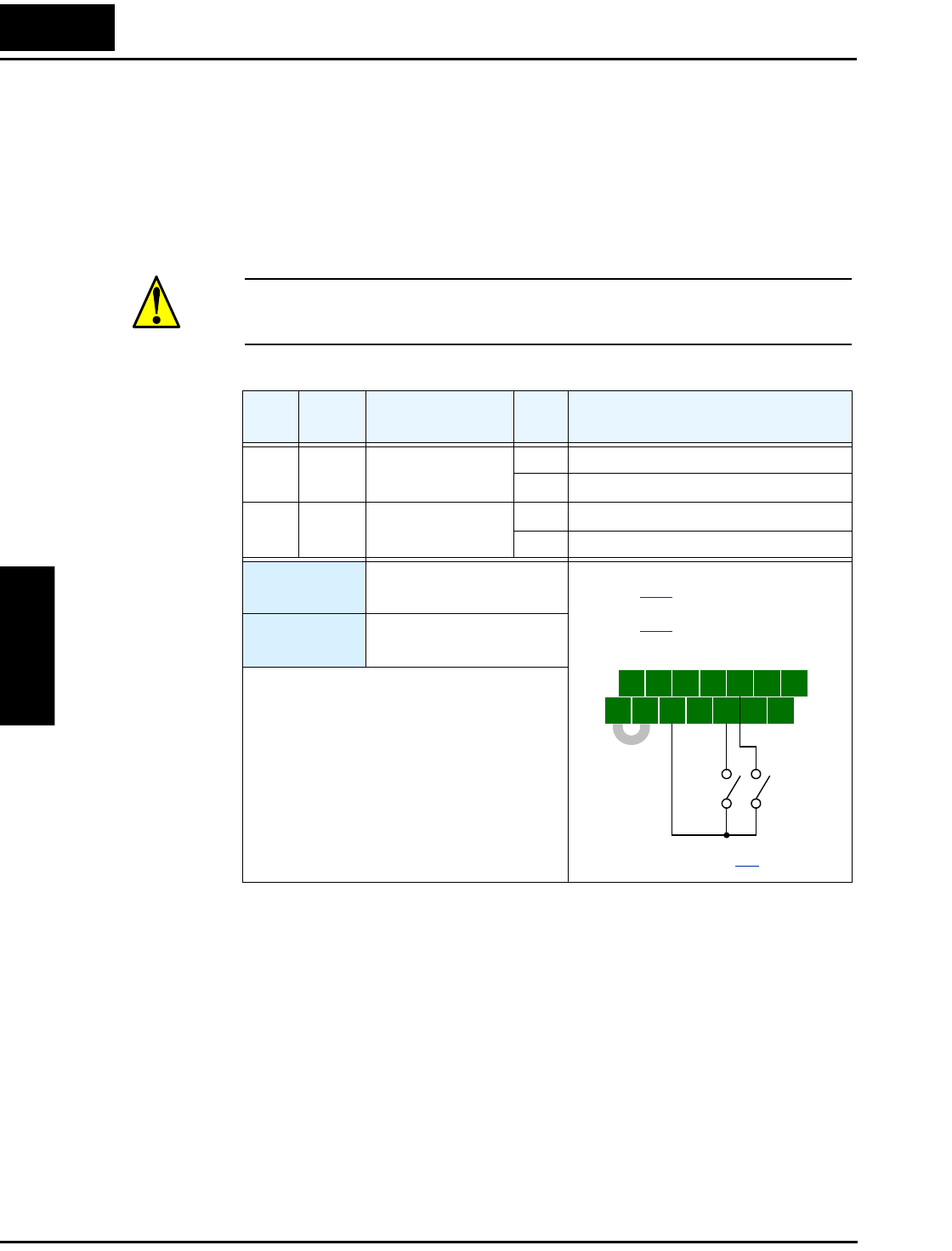

Opt.

Code

Symbol Function Name

Input

State

Description

23 PID PID Disable ON Disables PID loop execution

OFF Allows PID loop execution if A71=01

24 PIDC PID Clear ON Force the value of the integrator to zero

OFF No change to PID loop execution

Valid for

inputs:

C001, C002, C003, C004,

C005, C006, C007, C008

Required

settings:

A071

Notes:

• The use of [PID] and [PIDC] terminals are

optional. Use A071=01 if you want PID loop

control enabled all the time.

• Do not enable/disable PID control while the

motor is running (inverter is in Run Mode).

• Do not turn ON the [PIDC] input while the

motor is running (inverter is in Run Mode).

5 3 1

7 6 4 2

8

FW

TH

PLC

CM1

P24

CM1

See I/O specs on page 4–9.

Example: (Requires input configuration—

see page 3–47

. Jumper position shown is

for –xFU/-xFR models; for –xFE models,

see page 4–12

.)

PIDC

PID