SJ300 Inverter

Configuring Drive

Parameters

3–5

Operational

Modes

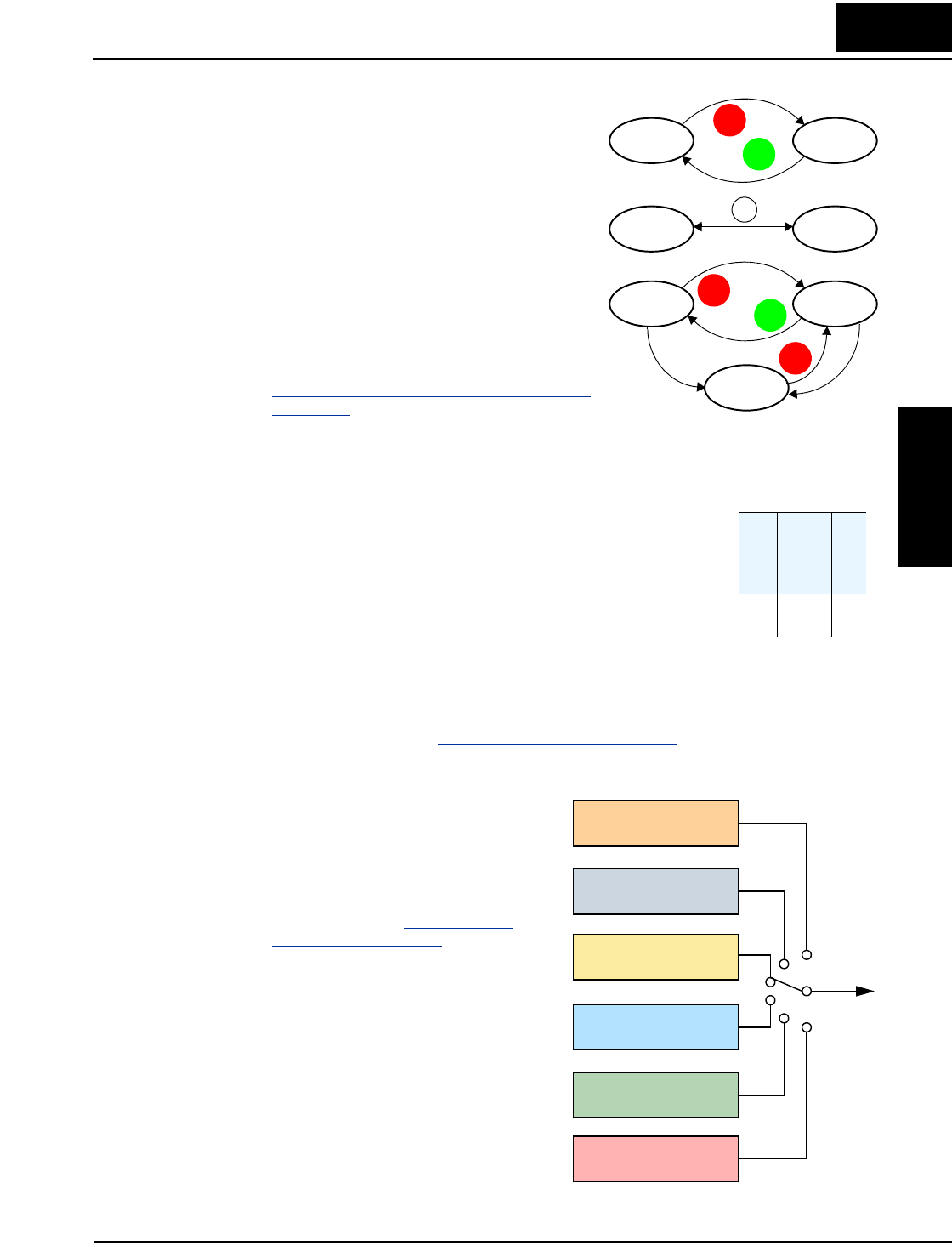

The RUN and PGM LEDs tell just part of the story;

Run Mode and Program Modes are independent

modes, not opposite modes. In the state diagram to

the right, Run alternates with Stop, and Program

Mode alternates with Monitor Mode. This is a very

important ability, for it shows that a technician can

approach a running machine and change some

parameters without shutting down the machine.

The occurrence of a fault during operation will

cause the inverter to enter the Trip Mode as shown.

An event such as an output overload will cause the

inverter to exit the Run Mode and turn OFF its

output to the motor. In the Trip Mode, any request

to run the motor is ignored. You must clear the

error by pressing the Stop/Reset switch. See

“

Monitoring Trip Events, History, & Conditions”

on page 6–5.

Run Mode Edits The inverter can be in Run Mode (inverter output is controlling motor) and still allow you to

edit certain parameters. This is useful in applications that must run continuously, yet need some

inverter parameter adjustment.

The parameter tables in this chapter have a column titled “Run Mode

Edit.” An Ex mark ✘ means the parameter cannot be edited; a Check

mark ✔ means the parameter can be edited. You’ll notice in the table

example to the right the two adjacent marks: “✘ ✔”. The two marks

(that can also be “✘ ✘” or “✔ ✔”) correspond to these levels of access

to editing:

• Low-access level to Run Mode edits (indicated by left-most mark)

• High-access level to Run Mode edits (indicated by right-most mark)

The Software Lock Setting (parameter B031) determines the particular access level that is in

effect during Run Mode and access in other conditions, as well. It is the responsibility of the

user to choose a useful and safe software lock setting for the inverter operating conditions and

personnel. Please refer to “

Software Lock Mode” on page 3–36 for more information.

Control

Algorithms

The motor control program in the SJ300

inverter has several sinusoidal PWM

switching algorithms. The intent is that you

select the best algorithm for the motor

characteristics in your application. Each

algorithm generates the frequency output in

a unique way. Once configured, the

algorithm is the basis for other parameter

settings as well (see “

Torque Control

Algorithms” on page 3–14). Therefore,

choose the best algorithm early in your

application design process.

RUN

STOP

RESET

FUNC.

Run Stop

Monitor Program

RUN

STOP

RESET

STOP

RESET

Run Stop

Fault

Tri p

Fault

Run

Mode

Edit

Lo Hi

✘ ✔

Output

V/f control,

constant torque

V/f control,

variable torque

V/f control, free-

setting curve

Inverter Control Algorithms

Sensorless vector

(SLV) control

SLV control,

0Hz domain

Vector control with

sensor