SJ300 Inverter

Configuring Drive

Parameters

3–31

The torque developed in a motor is directly proportional to the current in the windings, which is

also proportional to the heat generated (and temperature, over time). Therefore, you must set

the thermal overload threshold in terms of current (amperes) with parameter B012. The range is

50% to 120% of the rated current for each inverter model. If the current exceeds the level you

specify, the inverter will trip and log an event (error E5) in the history table. The inverter turns

the motor output OFF when tripped. Separate settings are available for the second and third

motors (if applicable), as shown in the table below.

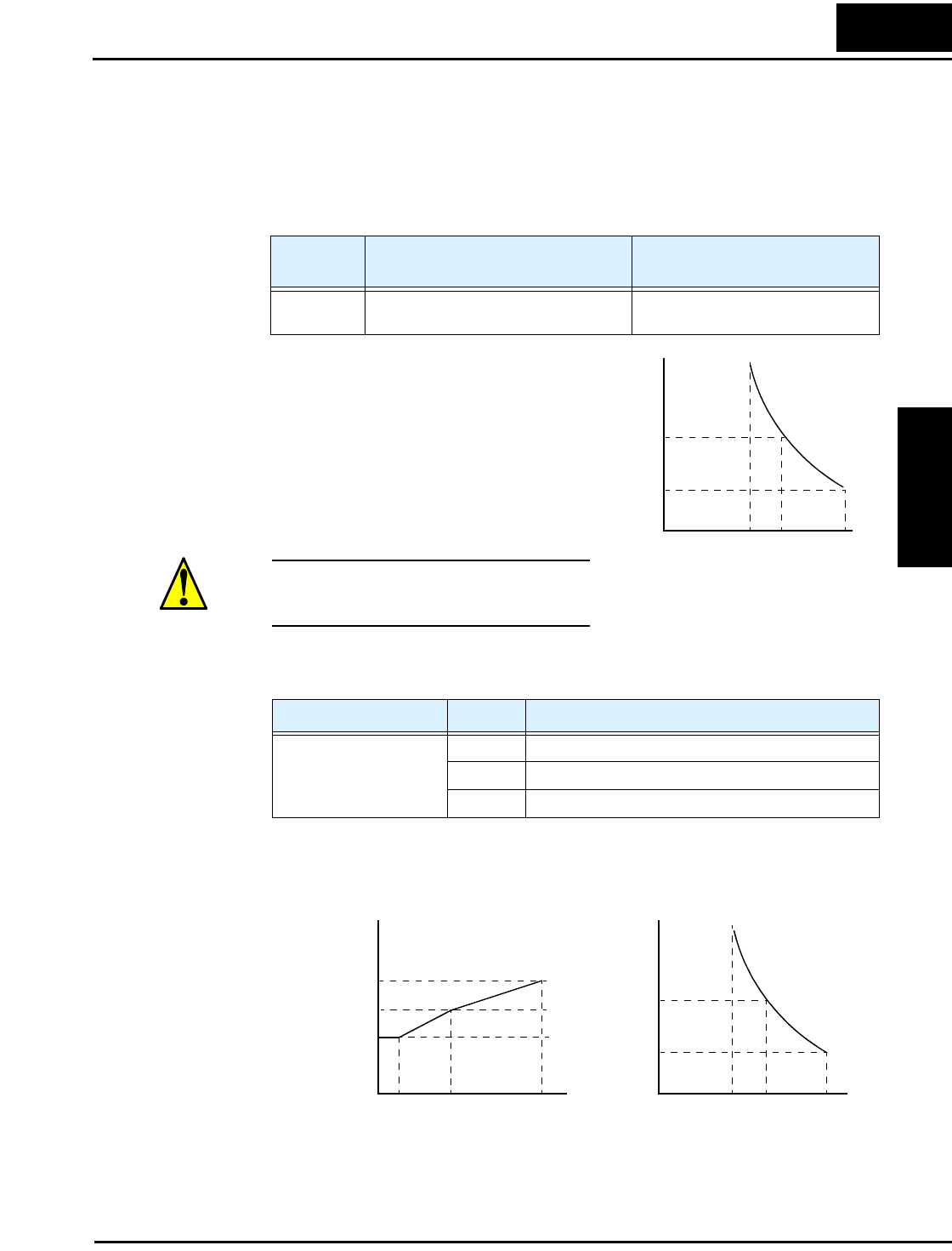

For example, suppose you have inverter model

SJ300-110LFE. The rated motor current is 46A.

The setting range is (0.2 * 46) to (1.2 *46), or

9.2A to 55.2A. For a setting of B012 = 46A

(current at 100%), the figure to the right shows

the curve.

The electronic thermal characteristic adjusts the

way the inverter calculates thermal heating,

based on the type of load connected to the motor,

as set by parameter B013.

CAUTION: When the motor runs at lower

speeds, the cooling effect of the motor’s internal

fan decreases.

The table below shows the torque profile settings. Use the one that matches your load.

Reduced Torque Characteristic – The example below shows the effect of the reduced torque

characteristic curve (for example motor and current rating). At 20Hz, the output current is

reduced by a factor of 0.8 for given trip times.

Function

Code

Function/Description Data or Range

B012 / B212

/ B312

Electronic thermal setting (calculated

within the inverter from current output)

Range is 0.2 * rated current to

1.2 * rated current

Function Code Data Function/Description

B013 / B213 / B313

00 Reduced torque

01 Constant torque

02 Free-setting

Tr ip

time (s)

Trip current at 60 Hz

60

0.5

0

53.4 69 92

A

116% 150% 200%

Tr ip

time (s)

Reduced trip current at 20 Hz

Trip current

reduction

factor

x 1.0

x 0.8

x 0.6

0

520 60

Hz A

60

0.5

0

73.642.7 55.2

92.8% 120% 160%