SJ300 Inverter

Operations

and Monitoring

4–71

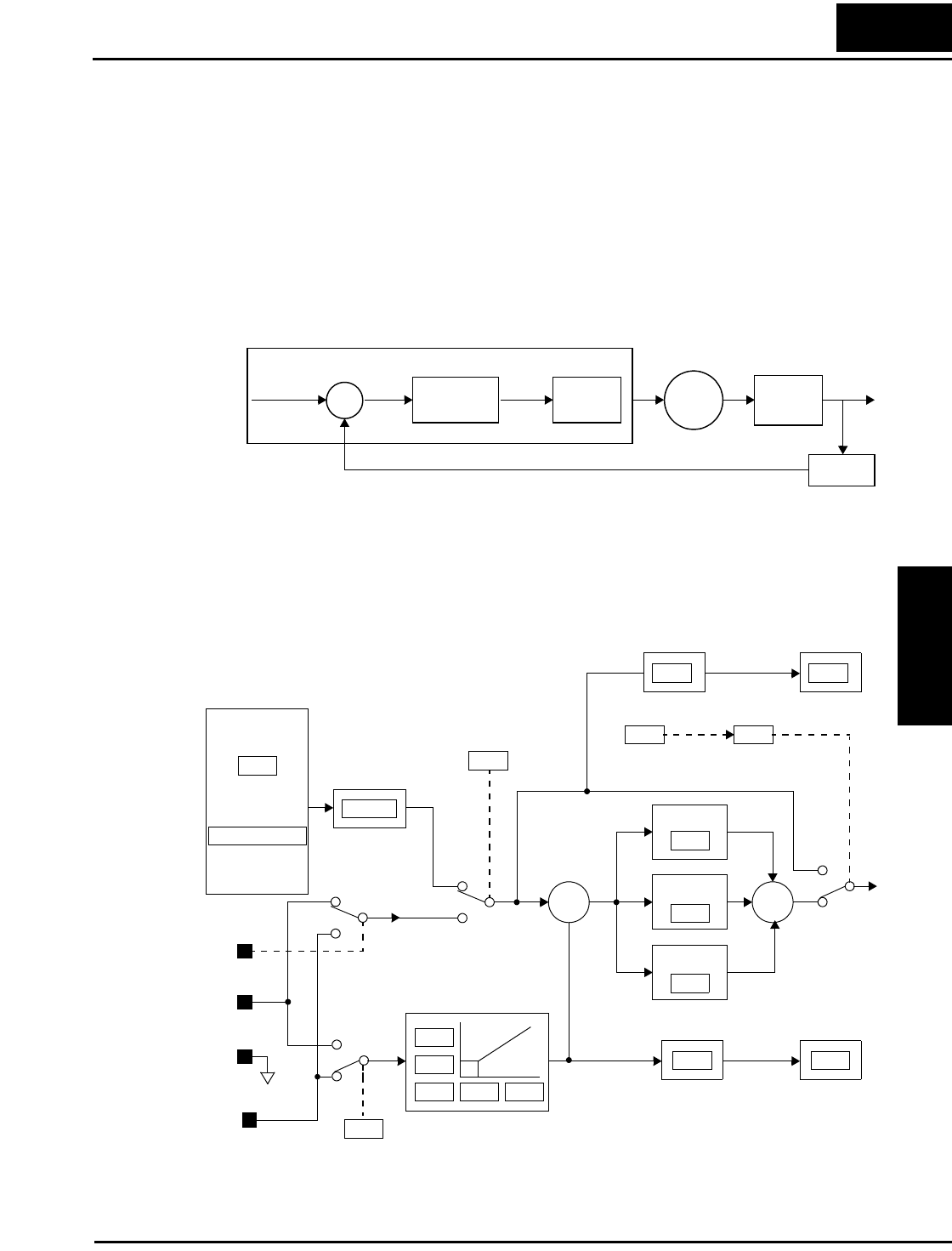

PID Loop Operation

In standard operation, the inverter uses a reference source selected by parameter A001 for the

output frequency, which may be a fixed value (F001), a variable set by the front panel potenti-

ometer, or value from an analog input (voltage or current). To enable PID operation, set A071 =

01. This causes the inverter to calculate the target frequency, or setpoint. An optional intelligent

input assignment (code 23), PID Disable, will temporarily disable PID operation when active.

A calculated target frequency can have a lot of advantages. It lets the inverter adjust the motor

speed to optimize some other process variable of interest, potentially saving energy as well.

Refer to the figure below. The motor acts upon the external process. To control that external

process, the inverter must monitor the process variable. This requires wiring a sensor to either

the analog input terminal [O] (voltage) or terminal [OI] (current).

When enabled, the PID loop calculates the ideal output frequency to minimize the loop error.

This means we no longer command the inverter to run at a particular frequency, but we specify

the ideal value for the process variable. That ideal value is called the setpoint, and is specified

in the units of the external process variable. For a pump application it may be gallons/minute,

or it could be air velocity or temperature for an HVAC unit. Parameter A075 is a scale factor

that relates the external process variable units to motor frequency. The figure below is a more

detailed diagram of the PID function.

∑

PID

Calculation

ErrorSetpoint

SP

PV

Freq.

Inverter

Output

Motor

External

Process

Sensor

Process Variable (PV)

Inverter

Analog input

Monitor

P gain

I gain

D gain

∑

Analog input scaling

∑

Voltage

O

OI

L

Current

A GND

PID V/I

input select

Process Variable

(Feedback)

Scale factor

Frequency

setting

Scale factor

Setpoint

(Target)

Scale factor

reciprocal

Multi-speed

settings

Standard

setting

Frequency

source select

Potentiometer

on keypad

Error

[AT]

V/I input

select

PV

SP

A001

A075 F001

F001

1/A075

A020 to A035

A072

A073

A075 D004

A074

A076

A011

A015

A012

A013 A014

A071

PID Enable

C023

PID Disable

optional

intelligent input

PID

Normal