ACU-RITE 3500i 75

4.2 Tool Data

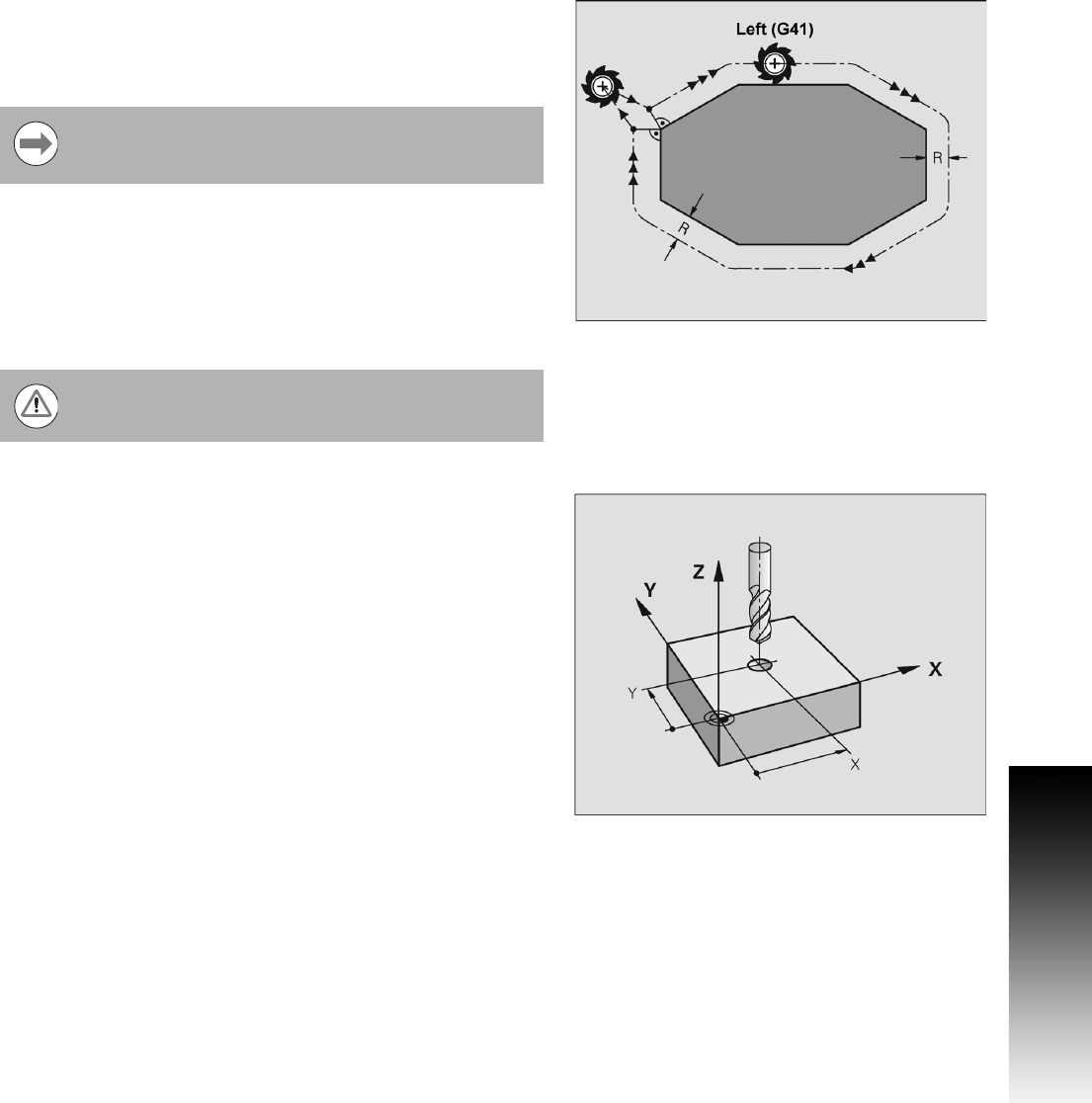

Tool Radius Compensation

When tool compensation is not active, the CNC positions the tool's

center on the programmed path. When programming a part profile,

the cutting edge must be half a diameter away from the path. Using

radius compensation moves the cutting edge half a diameter away

from the path.

This enables you to program the coordinates along the part profile. You

do not need to adjust the path to compensate for tool diameter.

Most moves can be compensated. Specify right-hand or left-hand

compensation. “Right” or “Left” refers to the side of the path to

which the tool offsets, as viewed from behind a moving tool. If the tool

is to the left of the work, use Left (G41). If the tool is to the right of the

work, use Right (G42). Refer to chapter 11 "G-Code" on page 364.

Contouring without radius compensation

The tool center moves in the working plane along the programmed

path or to the programmed coordinates.

Applications: Drilling and boring, pre-positioning.

When tool compensation is active, the CNC offsets the

tool by half a diameter to position the cutting edge of the

tool on the programmed path.

Use tool compensation with lines and arcs only.