178 7 Programming: Canned Cycles, sub-programs

7.2 Canned Cycles

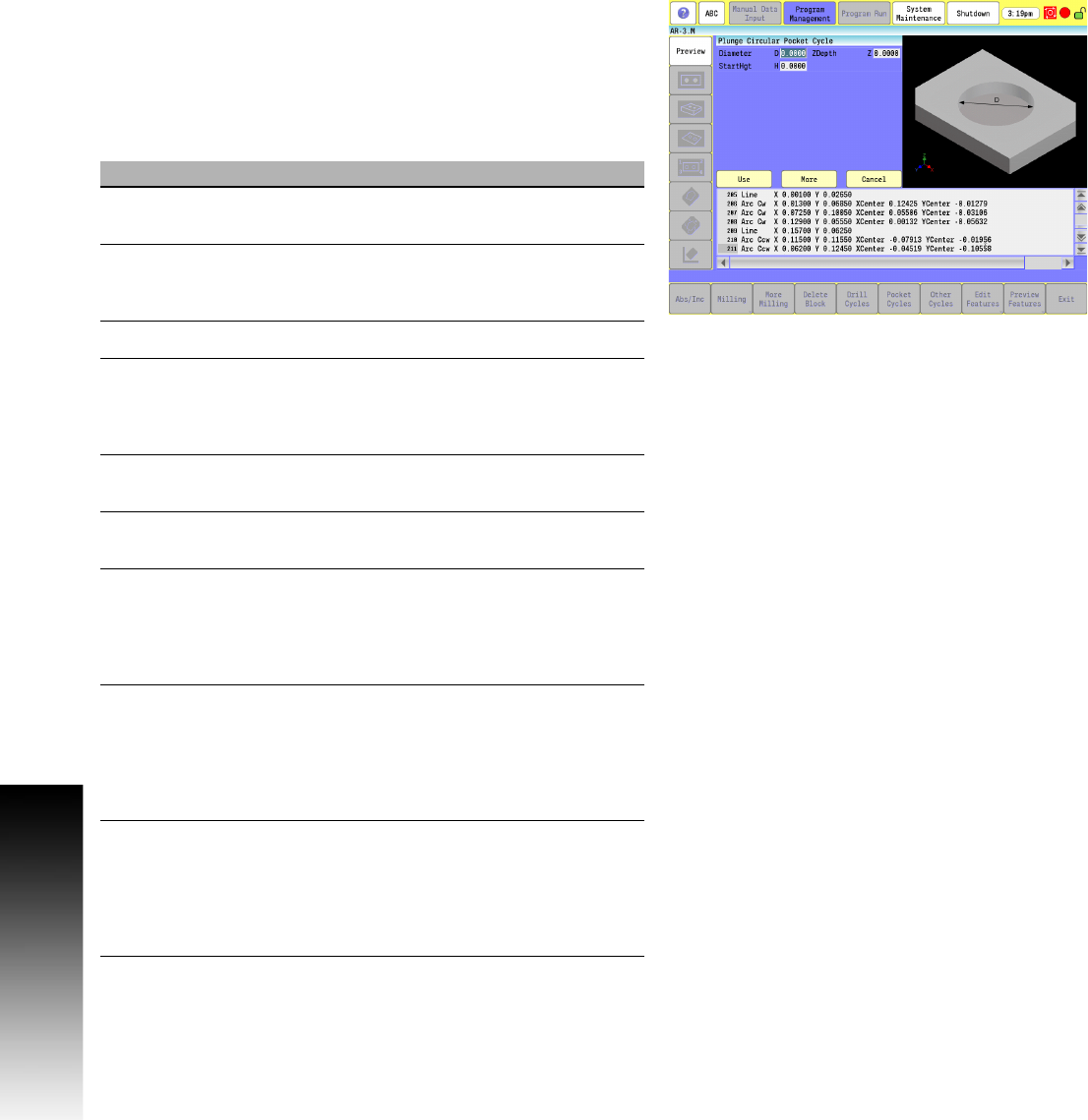

Plunge Circular Pocket Cycle

Use the plunge circular pocket cycle for carbide tooling, when a

multiple-axis ramp-in move is not possible. The Z-axis plunges

(single axis) to programmed depths. You must position the tool

directly over the center of the pocket prior to the plunge circular

pocket cycle block, or use the X Y words.

Activate the tool prior to programming so the cutter diameter is

known.

Field Code Description

Diameter D Diameter of pocket in X and Y axes.

(Required)

StartHgt H Z absolute starting height (0.1” or 2 mm

above surface). Executed in rapid.

(Required)

ZDepth Z Absolute depth of pocket. (Required)

StepOver A The distance the tool steps over (width of

cut) in the X and Y axes as it mills out the

pocket. Defaults to tool radius, which is the

max.

XCenter X X coordinate of the pocket center point.

Defaults to current position.

YCenter Y Y coordinate of the pocket center point.

Defaults to current position.

DepthCut B The depth of each cut per pass. Defaults to

tool diameter. Max is the full ZDepth in

parameter Z, less bottom finish stock. A

negative value will cause the finish pass to

finish the side walls in steps down.

FinStock S Amount of stock left by the roughing

passes for a finish pass. This amount

applies to the sides and bottom unless R

(SideStock) is defined; then, S (FinStock)

only applies to the bottom. Default is no

stock left.

SideStock R Amount of stock left by the roughing

passes for a finish pass. This amount

applies to the sides and bottom unless R

(SideStock) is defined; then, S (FinStock)

only applies to the bottom. Default is no

stock left.