294 10 CAM: Programming

10.1 CAM Programming

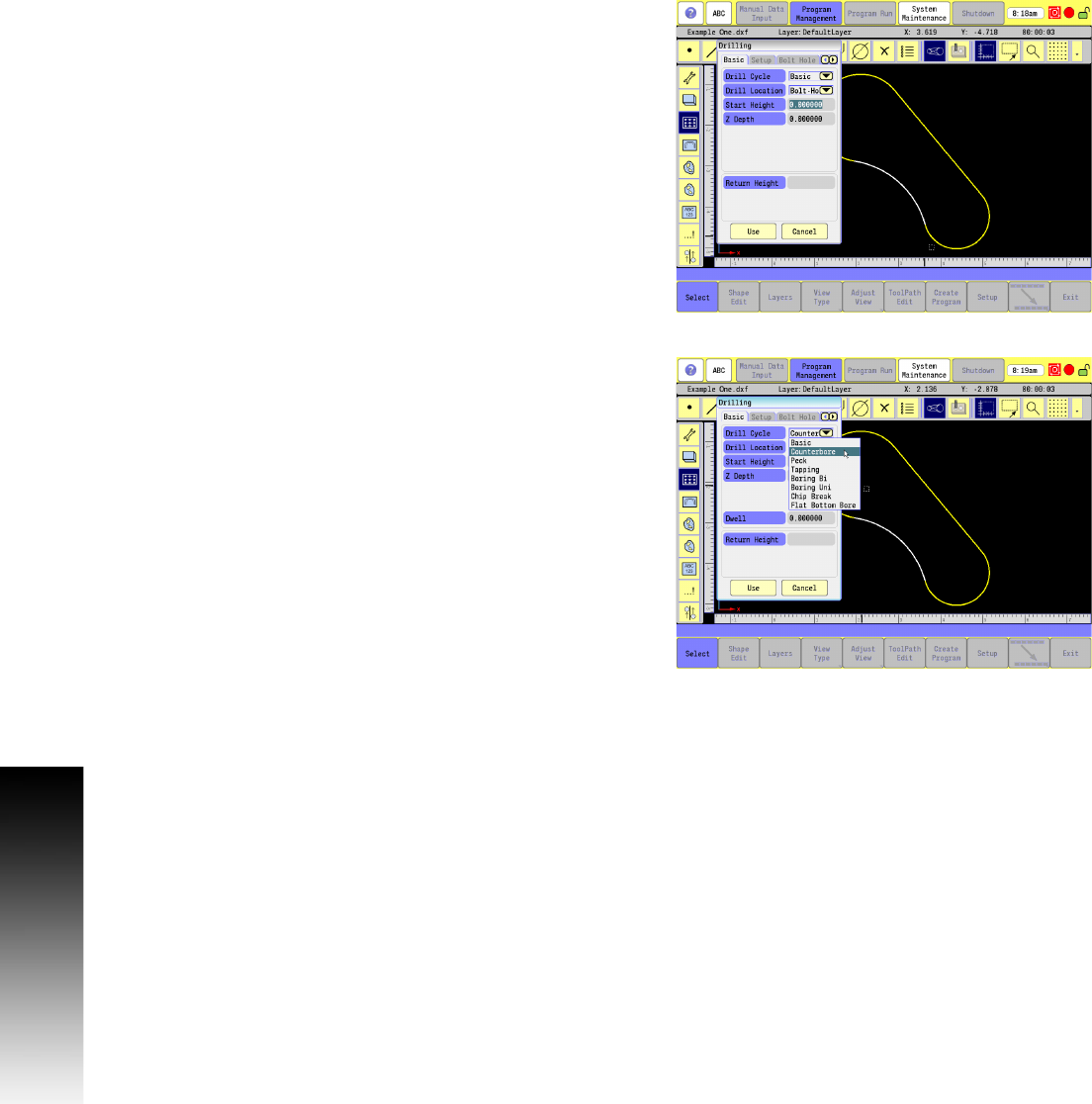

Drilling Cycle:

The Drilling tool path defines a drill cycle type, location, and

parameters for drilling. Certain parameters apply only to specific

cycles. These parameters appear as needed based on the selected

Drill Cycle.

The following describes the various Drill Cycles available.

Drill Cycle: Basic

A basic drilling cycle is generally used for center drilling or hole

drilling that does not require a pecking motion. It feeds from the

Start Height to the specified Z Depth at a given Feed, then rapids to

the Return Height.

Drill Cycle: Counterbore

A counter bore cycle is generally used for counter boring. It feeds

from the Start Height to Z Depth, dwells for specified time, then

rapids to the Return Height.

Drill Cycle: Peck

A peck drilling cycle is generally used for peck drilling relatively

shallow holes. The peck drilling cycle feeds from the Start Height to

the first peck depth (calculated so that all pecks are equal and do not

exceed the maximum peck distance programmed in Peck). Then

rapid retracts to Start Height (to clear chip), rapids down to previous

depth less .02", and continues this loop until it reaches the Z Depth.

It then rapid retracts to the Return Height.

Drill Cycle: Tapping

A tapping cycle is used for tapping holes. During a tapping cycle the

tool feeds from the Start Height to Z depth; the spindle stops and

reverses; the tool feeds to the Return Height; and the spindle stops

and reverses again.

Drill Cycle: Boring Bidirectional

A bidirectional boring cycle is generally used to make a pass in each

direction on a bore or to tap with a self-reversing tapping head. It

feeds from the Start Height to Z depth, and then feeds back to the

Return Height.