ACU-RITE 3500i 161

7. 2 C a n n e d C y c l e s

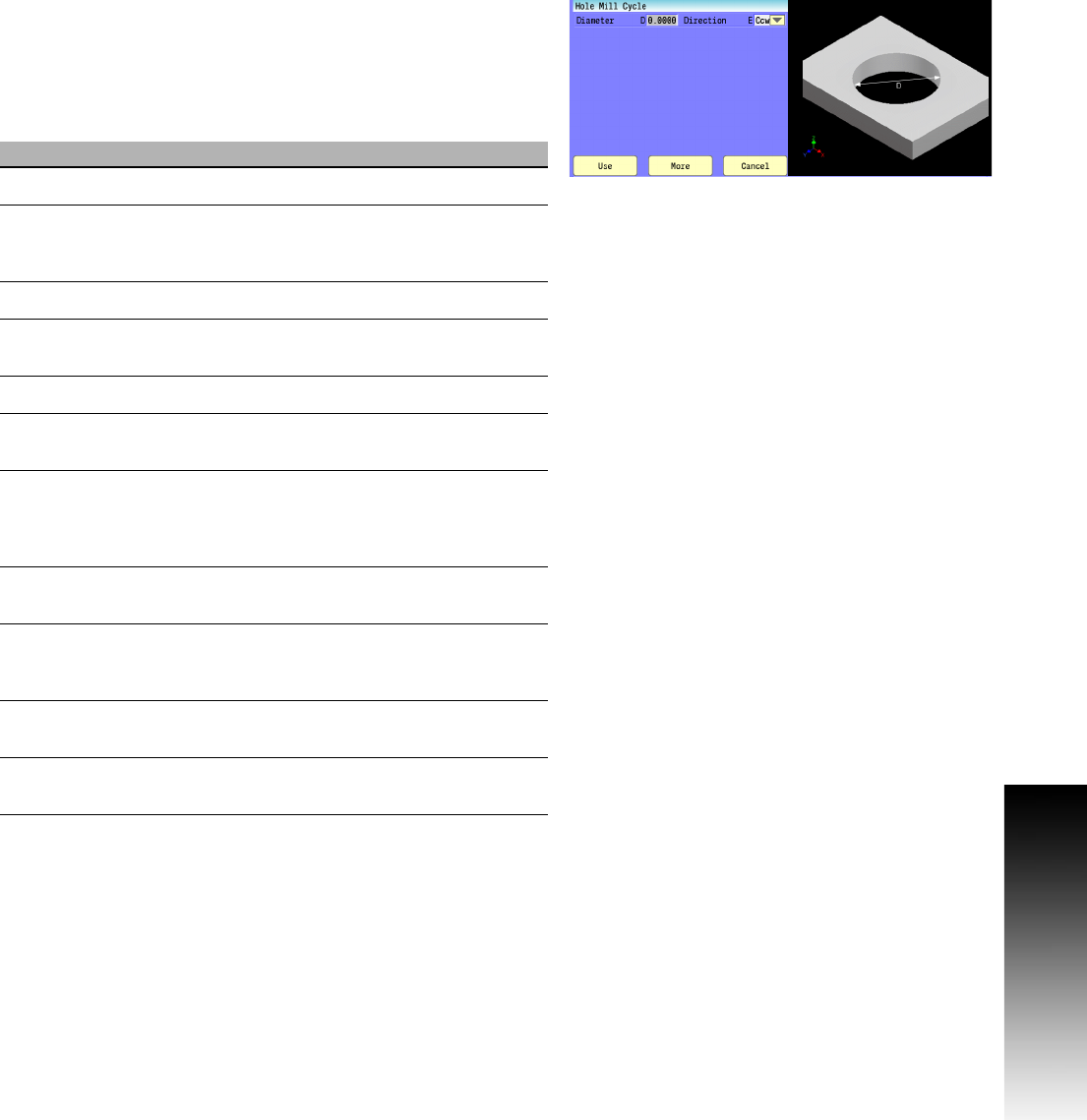

Hole Mill Cycle

Use the hole milling cycle to machine through holes or

counter-bores. You can position the tool at the hole center prior to

the this block. Activate a tool prior to, so that the CNC knows the

tool diameter.

If you do not provide Z and H, program a separate Z move to raise

the tool out of the hole after the cycle.

G-code format: G76

Field Code Description

Diameter D Diameter of hole. (Required)

Direction E Select the direction: CCW (climb milling) or

CW (conventional milling). Default is CCW

(Required)

ZDepth Z The absolute depth of the finished pocket.

StartHgt H Absolute Z position to which the CNC

rapids before feeding into the workpiece.

DepthCut B Z-axis increment used for each pass.

ReturnHgt P Z-axis height (must be equal to or above

"H").

FinStock S Finish-stock amount per side. If you enter

a negative value, stock is left, but no finish

pass occurs. If you do not enter a value, no

finish stock is left.

XCenter X X coordinate of the center. Default: Pocket

centers at present position.

YCenter Y Y coordinate of the center. If no coordinate

is provided, default is set to present

position.

RoughFeed J Rough-pass feedrate. Defaults to last

programmed feedrate.

FinFeed K Finish-pass feedrate. Defaults to last

programmed feedrate.