9-16

Chapter 9 MXYX

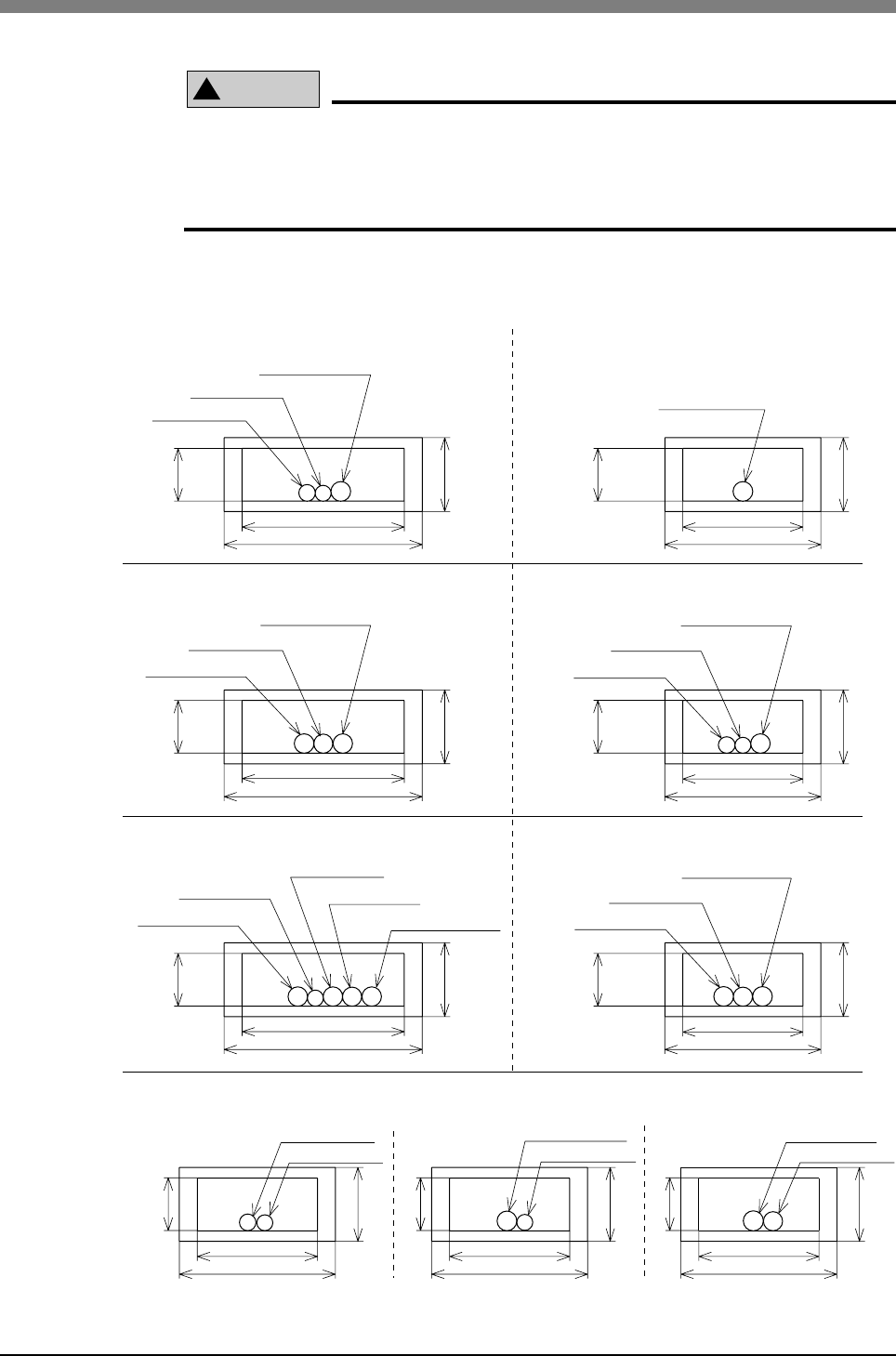

4-1-2 Cable carrier specifications

!

CAUTION

When setting the harness and air tube into the cable carrier, make sure that the

total cross-sectional area of all wires and pipes, including the YAMAHA cable,

inside the cable carrier does not exceed 30% of the cable carrier’s cross-sec-

tional area. (This ratio is called the cable carrier space factor.)

The cross-sectional shape of the cable carrier, and the shape of the cable mounted

initially by YAMAHA are shown below.

Fig. 9-15

User I/O wire φ10.1

User I/O wire φ10.1

Power wire φ7.6

Signal wire φ8.2

User I/O wire φ10.1

User I/O wire φ10.1

Power wire φ9.8

Power wire φ9.8

Power wire φ7.6

Signal wire φ10.1

Signal wire φ11

Signal wire φ10.1

User I/O wire φ10.1

Power wire φ7.6

Signal wire φ8.2

User I/O wire φ10.1

Power wire φ9.8

Signal wire φ 11

25

77

93

57

73

57

73

57

73

93

25

77

93

77

25

25

2525

35

353535

3535

Power wire φ9.8

Signal wire φ11

Power wire φ7.6

Signal wire φ8.2

57

73

25

35

57

73

25

35

57

73

25

35

2-axis specifications X-Y cable carrier

3-axis specifications X-Y cable carrier

4-axis specifications X-Y cable carrier

2-axis I/O specifications Y-axis cable carrier

3-axis specifications Y-Z cable carrier

4-axis specifications Y-Z cable carrier

XZ type 3-axis specifications Z-R cable carrier

4-axis specifications Z-R cable carrier

(ZRFL)

(ZFH)

(ZRFH)

Power wire φ7.6

Signal wire φ10.1