DR4300 Circular Chart Recorder

178 DR4300 Circular Chart Recorder Product Manual 12/03

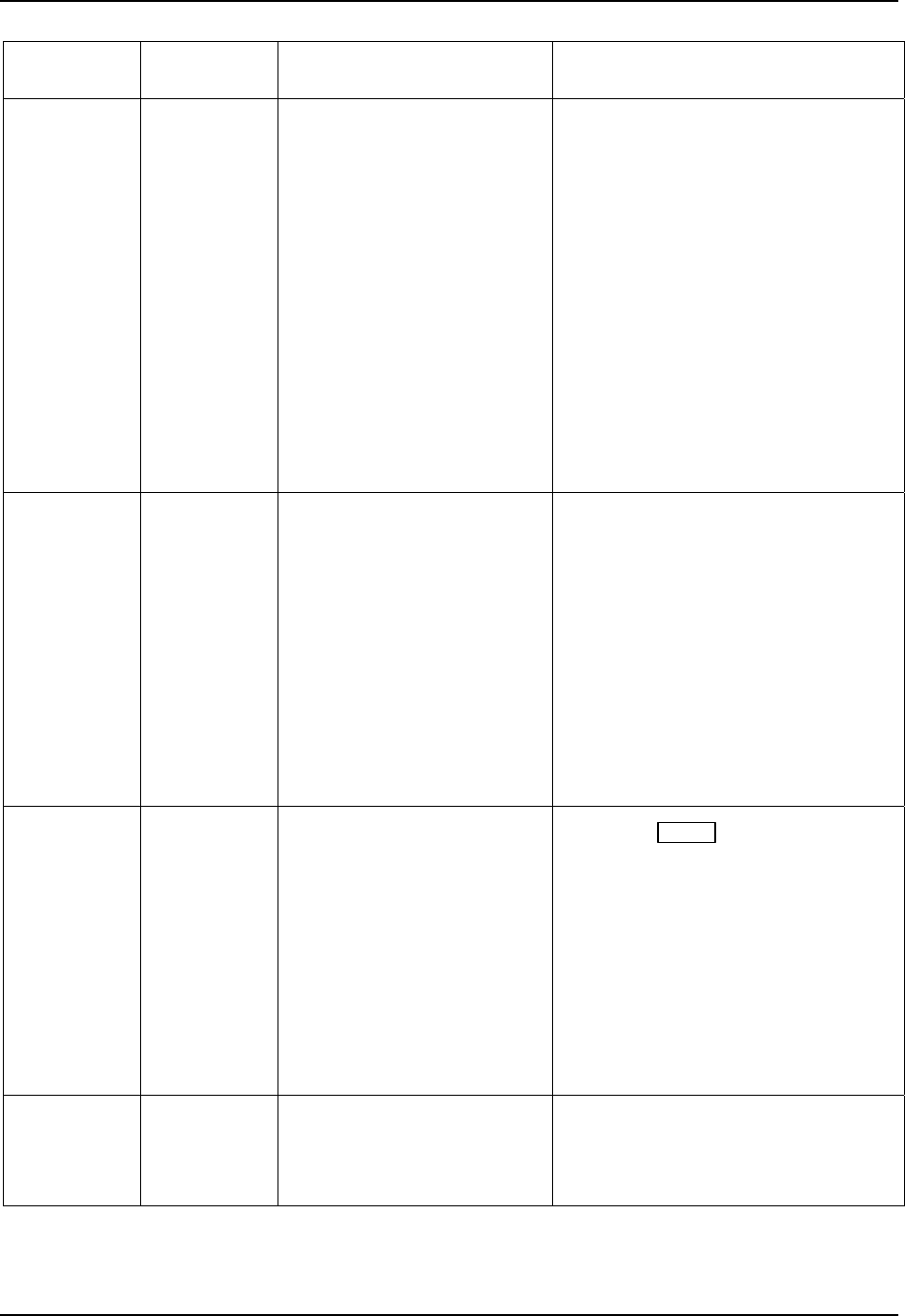

Lower Display

Indication

Type of Test

Reason For Failure

How to Correct the Problem

INP FL

background Recorder detects an input failure.

Two consecutive failures of input

1 integration (for example,

recorder cannot make analog to

digital conversion.)

1. Be sure the range and actuation are

configured correctly.

2. Check the input source.

3. See input set up group in Section 4 –

Configuration, Startup, and Operation of

Recorder with Display and change the “IN

TYP” or “LD CAL” to a different type.

Enter it, loop through the status tests,

then return the input type to the original

one.

4. Recalibrate if step 3 does not clear the

error. Refer to Section 5 – Input and

Output Calibration for Recorder with

Display.

5. Replace the printed circuit assembly for

the pen.

INPRNG

background Input out of range. The process

input is outside the range limits.

1. Make sure the range and actuation are

configured properly.

2. Check the input source.

3. See Section 4 – Configuration, Startup,

and Operation of Recorder with Display to

restore the factory or field calibration, as

applicable.

4. Field calibrate using the procedure in

Section 5 – Input and Output Calibration

for Recorders with Display.

5. Replace the printed circuit assembly for

the pen.

P1 ERR

P2 ERR

power-up

background

Indicates that one or more error

messages are active for the pen

channel for which values are not

on display.

For example, if value of INP1 is

on display, while the input for pen

2 fails, P2 ERR will be displayed.

This alerts the operator to the

need to switch the display to pen

2 to view the active error

messages associated with that

channel’s input and printed circuit

assembly.

1. Press the FUNC

key to toggle to the

other pen channel.

2. Watch the display to see all error

messages for the active channel.

3. Follow the procedure in this table for

each message displayed.

RAMTST

power-up RAM failure 1. Cycle power or press the reset switch

SW2 to see if the error clears.

2. If error does not clear, replace the printed

circuit assembly for the pen.