DR4300 Circular Chart Recorder

218 DR4300 Circular Chart Recorder Product Manual 12/03

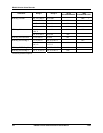

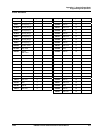

C.4 Setpoint Program Prompt Hierarchy

Table C-1 lists all the function prompts for Setpoint Program data configuration in the order of their

appearance. These prompts are available when SPPROG is enabled in the SPRAMP set up group

described in Section 4.

All parameters may be changed while the program is disabled or in HOLD.

Table C-1 Prompt Hierarchy and Available Selections

Lower Display

Prompt

Upper Display

Range of Setting

or Selection

Parameter

Definition

SPPROG

DIS

ENAB

SETPOINT PROGRAMMING—This must be set to ENAB

for the setpoint program feature to work, and for the

associated operating parameters to be displayed.

SPRAMP must be disabled. (See Section 4.)

DIS—Disabled

ENAB—Enabled

START 1

1,3,5,7,9,11,13,15,17,19,

21,23 [factory setting=1]

START SEGMENT FOR PROGRAM 1—Enter the

number of the first segment in Program 1.

END 1

2,4,6,8,10,12,14,16,18,20,22,

24 [factory setting=6]

END SEGMENT FOR PROGRAM 1—Enter the number

of the last segment in Program 1.

START 2

1,3,5,7,9,11,13,15,17,19,

21,23 [factory setting=7]

START SEGMENT FOR PROGRAM 2—Enter the

number of the first segment in Program 2.

END 2

2,4,6,8,10,12,14,16,18,20,22,

24 [factory setting=12]

END SEGMENT FOR PROGRAM 2—Enter the number

of the last segment in Program 2.

START 3

1,3,5,7,9,11,13,15,17,19,

21,23 [factory setting=13]

START SEGMENT FOR PROGRAM 3—Enter the

number of the first segment in Program 3.

END 3

2,4,6,8,10,12,14,16,18,20,22,

24 [factory setting=18]

END SEGMENT FOR PROGRAM 3—Enter the number

of the last segment in Program 3.

START 4

1,3,5,7,9,11,13,15,17,19,

21,23 [factory setting=19]

START SEGMENT FOR PROGRAM 4—Enter the

number of the first segment in Program 4.

END 4

2,4,6,8,10,12,14,16,18,20,22,

24 [factory setting=24]

END SEGMENT FOR PROGRAM 4—Enter the number

of the last segment in Program 4.

RECYCL

0 to 99

[factory setting=0]

RECYCLES—Enter the number of times the program

selected for execution will be repeated.

SOKDEV

–99.9 to 99.9 engineering

units

[factory setting=0.00]

SOAK DEVIATION—Enter the acceptable deviation from

setpoint during a soak cycle. If the PV differs from the

setpoint by more than the value of SOKDEV, soak time is

frozen.

There are no guaranteed soaks if SOKDEV = 0.