Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-50 F-50

COMMANDER 400

CHARGING CIRCUIT TEST (continued)

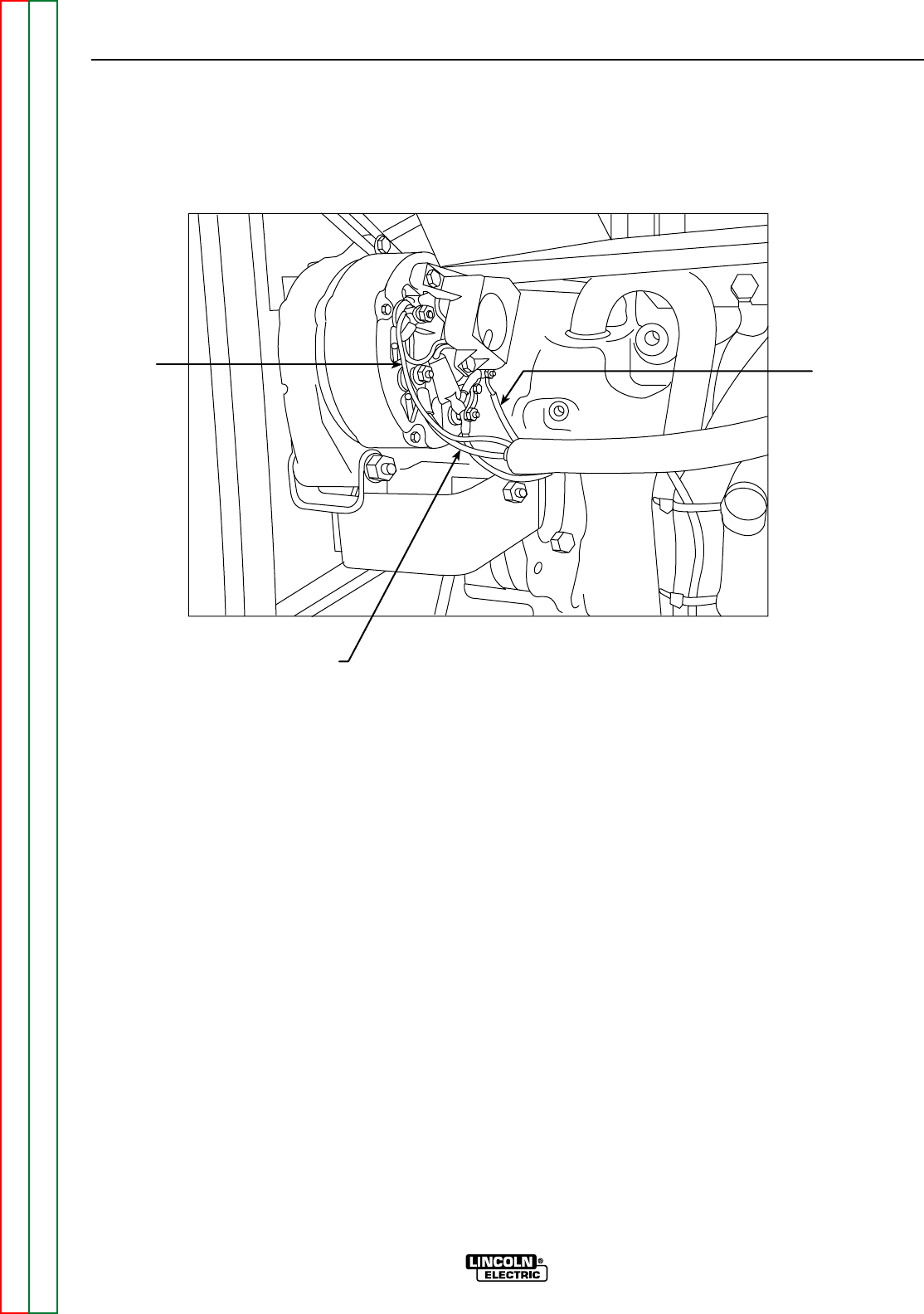

FIGURE F.22 – ENGINE ALTERNATOR LOCATION

#239

#238

#285(#281)

TEST PROCEDURE

1. Turn the engine off.

2. Perform the Case Cover Removal

Procedure up to Step 7.

3. Locate the engine alternator. See Figure F.22.

4. Start the engine and run it at high idle (1900

RPM).

5. Set the voltmeter for DC volts and measure

the DC volts at lead #239 to engine ground.

See the Wiring Diagram. Normal is 12.5 to

14.5VDC.

6. Set the voltmeter for DC volts and measure

the DC volts at lead #238 to engine ground.

See the Wiring Diagram. Normal is 12.5 to

14.5VDC.

7. Set the voltmeter for DC volts and measure

the DC volts at lead #285 to engine ground.

See the Wiring Diagram. Normal is 12.5 to

14.5 VDC.

NOTE: Some earlier machines may have a lead

#281 instead of #285. Lead #285 carries the

flashing voltage for the engine alternator. Battery

voltage should be present whenever the engine is

running. See the Wiring Diagram. On the earlier

machines, lead #281 carries the flashing voltage

for the engine alternator. Battery voltage should

be present whenever the start button (S2) is

pushed. See the Wiring Diagram.

8. If the correct flashing voltage is present and

the charging output voltage is low or missing,

the engine alternator may be faulty.

9. Stop the engine and check alternator V-belt

for proper tension. See the engine operation

manual.

10. Replace all case covers that were removed.

(See the Case Cover Removal Procedure.)