TROUBLESHOOTING AND REPAIR

FINE CONTROL POTENTIOMETER TEST (continued)

F-56 F-56

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TEST PROCEDURE

NOTE: In this test procedure, the positive output

stud is used for common.

1. Using the 5/16” nut driver, open the control panel

and tilt out. Remove the control board cover.

Put the LOCAL/REMOTE switch in the “LOCAL”

position. Set the range switch to the general fab-

rication tap. Start the machine.

There are high voltages present

inside the control box while the

machine is running. THE VOLTAGES

ARE HIGH ENOUGH TO KILL. Use

extreme caution to avoid the back-

side of the receptacles, breakers, and

terminal strip while checking voltages inside the

control box.

2. With the control potentiometer in the minimum

position, check the voltage at the control board

from J8 pin 8 to common. Voltage should be

approximately -.025 VDC.

3. Slowly turn the control potentiometer CW. The

voltage should steadily increase from approxi-

mately -.025 VDC in the minimum position to

approximately 5.00 VDC in the maximum posi-

tion. Also, the display on the control panel

should steadily increase from 50-575.

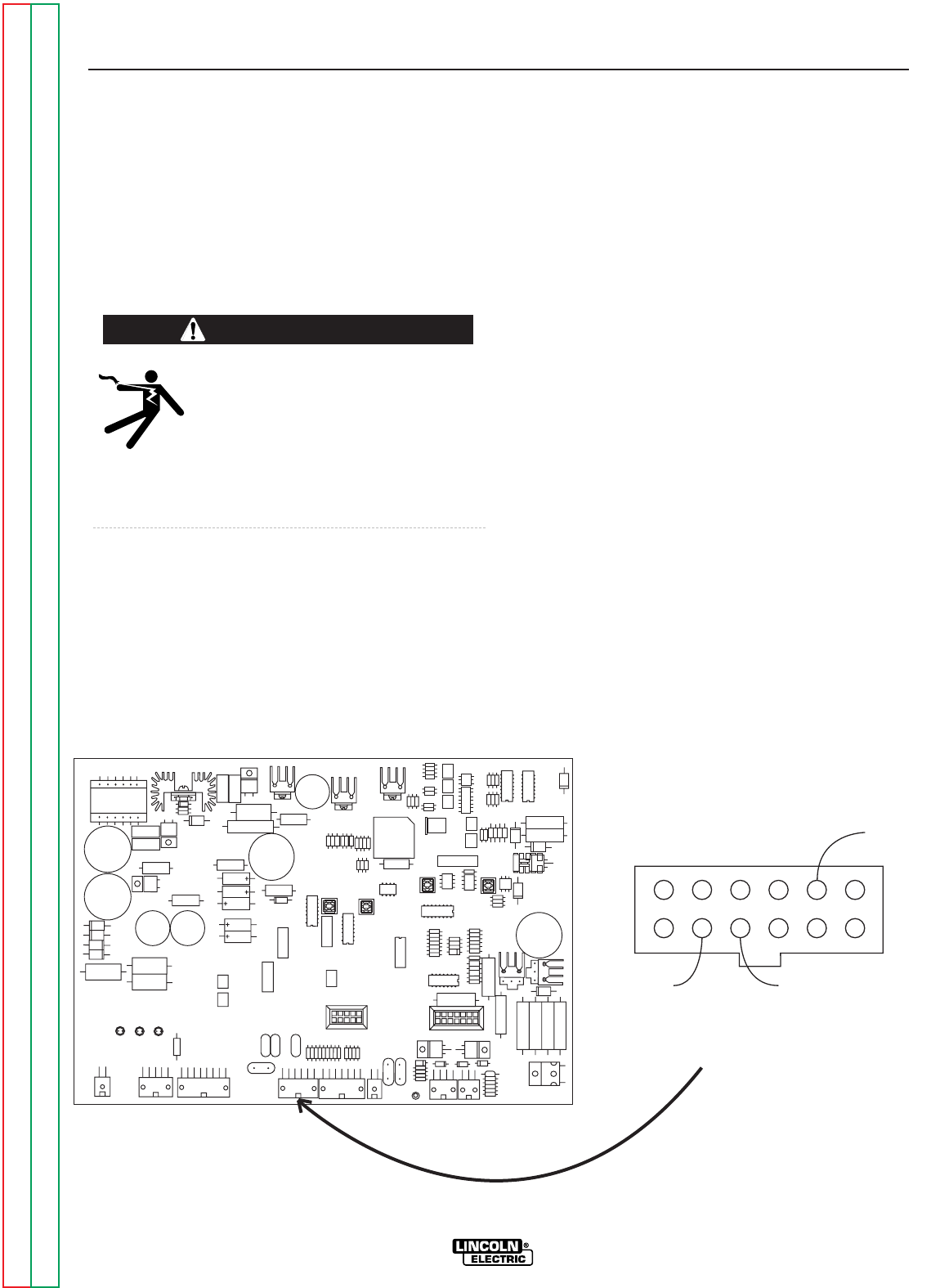

4. If step 2 or 3 fails, turn off the machine. At J8

pins 5,8, & 9, perform a resistance check of the

fine control potentiometer (the control poten-

tiometer is a 10K ohm potentiometer). See

Figure F.27. Also, check continuity of all fine con-

trol potentiometer leads and LOCAL/REMOTE

switch. If any of the leads, switch or poten-

tiometer fails the resistance check, replace the

faulty component.

5. If the leads, switch and potentiometer pass the

resistance check, disconnect the J8 from the

control board and start the machine. Check the

voltage from J8 pin 9 to common. The voltage

should be approximately 5.11 VDC. Check the

voltage from J8 pin 5 to common. The voltage

should be approximately -.049 VDC. If either

voltage check fails, replace the PC board.

6. Repeat steps 2-4 with the LOCAL/REMOTE

switch in the “REMOTE” position and a remote

control potentiometer hooked up to either

amphenol. When doing any continuity checks,

be sure to include the RF bypass PC board and

associated leads.

7. When the test is complete, replace the control

board cover and close the control panel.

WARNING

COMMANDER 400

J2

J6

J5

J8

J7

J1

J4

J22

J20

C112

Figure F.27 Control Board Plug J8 location

Plug J8

Pin #5

Pin #8

Pin #9