Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

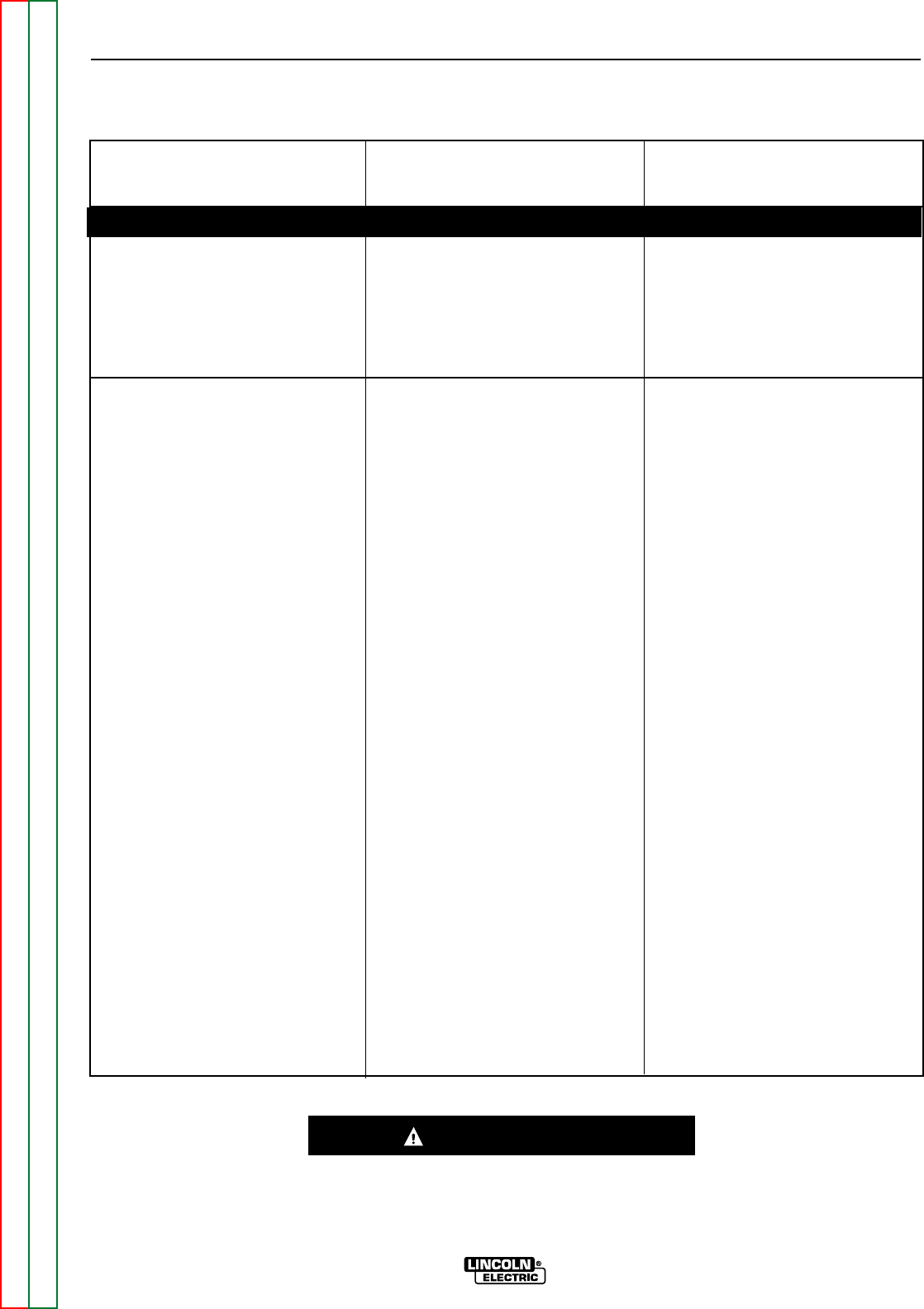

F-15 F-15

The welding arc is “hot”, “spattery”,

“cannonballs” or “flares up”. The

engine runs normally. The auxil-

iary power is normal. (Continued)

10. Check all waveforms as illus-

trated in the Oscilloscope

Wave forms Section.

11. Perform the Control Board

Power Supply Test.

Machine shuts down while arc

gouging and all lamp indicators on

front panel are lit. “ECL”, “ECH”,

or “CCS” appears on display as

machine is shutting down.

1. Check to make sure that the

machine settings match the

weld application.

2. Check to make sure the prop-

per carbon arc rod is being

used. The maximum carbon

arc rod for the Commander 400

is 5/16”.

3. Attempt to arc gouge at a less-

er current, if the application will

permit.

4. If the machine shuts down

while arc gouging in the gener-

al fab tap, use the CV tap

instead. This is also an accept-

able process.

1. Check for poor connections at

J4 pins 1, 2, 3, 6 & 7 at the con-

trol pc board. Also, perform the

Exciter Voltage Feedback

Test.

2. Check for loose or faulty con-

nections or wires at the T1, T2,

or T3 capacitor connection

block and back to the capacitor

bank. On machines equipped

with L10953-1 Exciter

Feedback module asbly, check

leads T1, T2, & T3 for faulty

connections.

3. Check for loose or faulty con-

nections at leads 268, 269 &

270 from the exciter pc board

to J4 pins 1, 2 & 3 on the con-

trol board.

4. Perform the Exciter Capacitor

Bank Test.

5. Check for poor connections at

the J1 molex plug at the control

pc board. Also, perform the

Shunt Calibration Test.

6. Perform the Engine Throttle

Adjustment Test.

7. Check exciter waveforms as

illustrated in the Oscilloscope

Waveforms Section.

COMMANDER 400

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

WELDING PROBLEMS

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353 (WELD).