Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

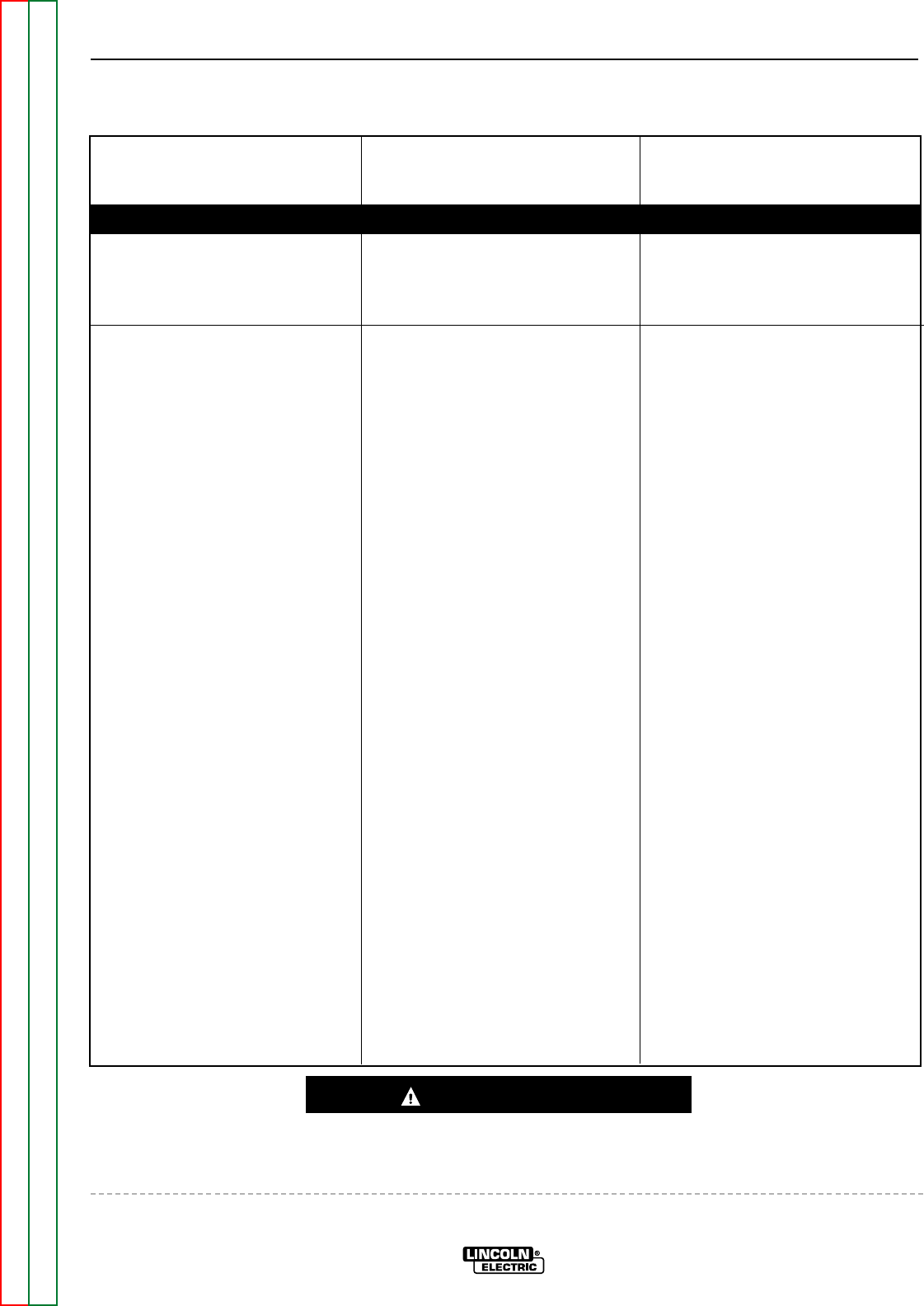

TROUBLESHOOTING & REPAIR

F-4 F-4

Commander 400

Observe Safety Guidelines TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353 (WELD).

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

Major physical or electrical damage

is evident.

No welding output in either CV or

Stick modes. Auxiliary power is nor-

mal and engine operates normally.

1. Contact your local Lincoln

Authorized Field Service Facility.

1. Place the Welding Terminals

switch in the “ALWAYS ON”posi-

tion. If the problem is solved, the

fault may be in the external con-

trol cable (if used), Leads #2 and

#4. See the Wiring Diagram.

2. Check the welding cables,

clamps, and electrode holder for

loose or faulty connections.

3. With the engine at high idle

(1900 RPM), and the machine in

the general fab tap, Check for

the presence of 70VDC at the

output terminals of the

Commander 400.

1. Contact the Lincoln Electric

Service Department. 1-800-833-

9353 (WELD).

1. Check for loose or faulty con-

nections on the heavy current

carrying leads between the out-

put bridge and the output termi-

nals. Also check for broken

leads at the weld choke. See

the Wiring Diagram.

2. Check the welding terminal

switch (S6) and leads 2 &4 back

to J8 pins 2 & 3 of the control

board.

3. Check for poor connections at

J6 pins 1,2 & 3 molex plug at the

control PC board. Also check

leads G1,G2 & G3 to each SCR.

These are SCR gate drive out-

puts.

4. Check leads W1 thru W6 for

loose or faulty connections. See

the wiring diagram.

5. Perform the Stator Voltage Test.

6. Perform the SCR/Diode Bridge

Test.

7. Perform the Control Board

Power Supply Test.