TROUBLESHOOTING AND REPAIR

SHUNT CALIBRATION TEST (continued)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TEST PROCEDURE

NOTE: In this test procedure, the positive output

stud is used for common.

1. Using the 5/16” nut driver, open the control panel

and tilt out. Remove the control board cover.

Start the machine.

There are high voltages present

inside the control box while the

machine is running. THE VOLTAGES

ARE HIGH ENOUGH TO KILL. Use

extreme caution to avoid the back-

side of the receptacles, breakers, and

terminal strip while checking voltages inside the

control box.

2. Set the range switch to the CC/General fabrica-

tion tap. Using the fine control pot, set the pre-

set amps on the display to 300 amps.

3. Using a grid bank, load the machine to 300 amps

at 25 volts using an external ammeter and volt-

meter.

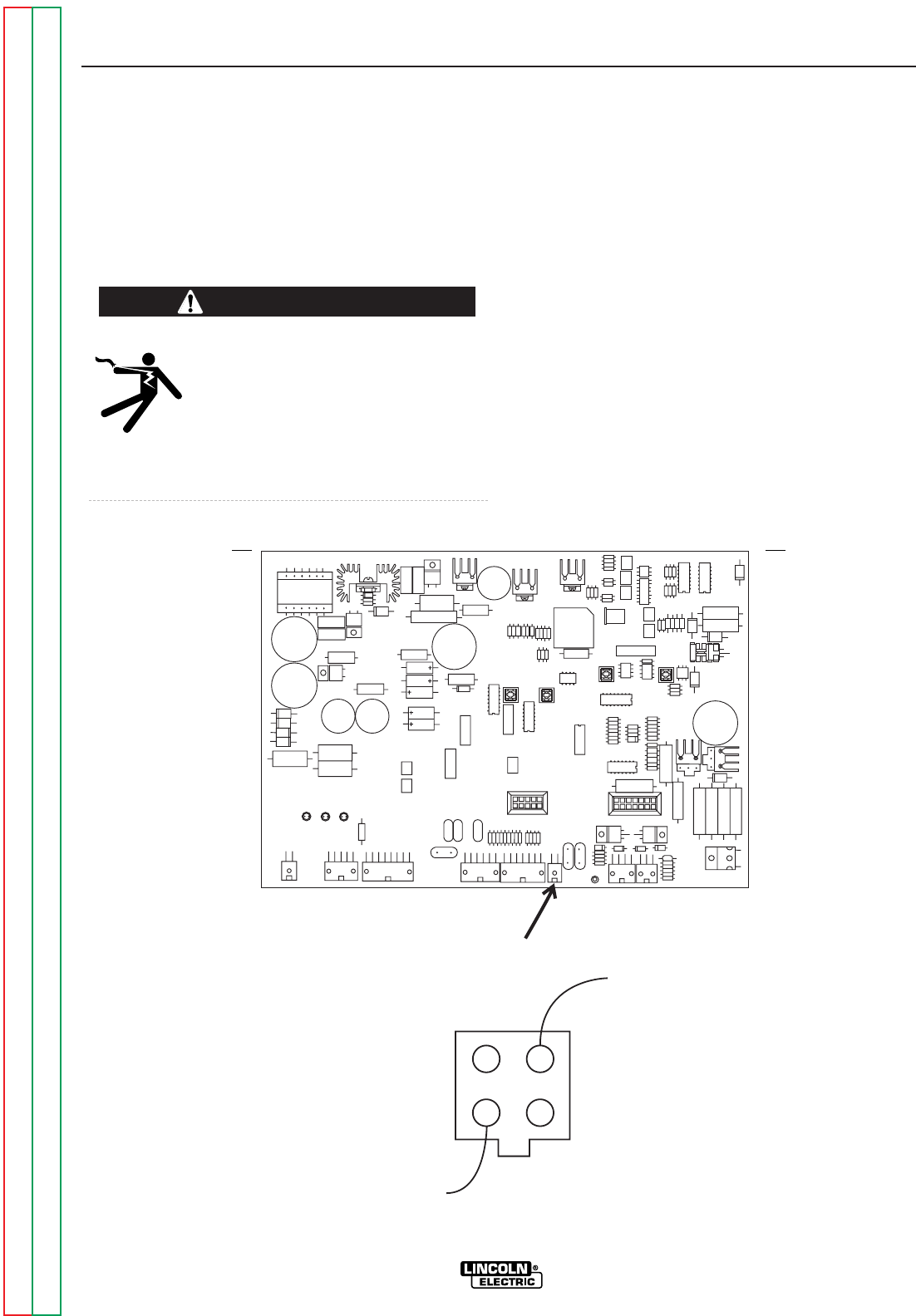

4. At the control board, measure the voltage from

J1 pin 3 (pos. lead) to J1 pin 2 (neg. lead). See

Figure F.29. The voltage should be 25 mVDC +/-

5%. The current reading on the display should

be within +/- 5% with the external ammeter. See

Figure F.29.

5. If step 4 fails, the shunt is out of calibration and

must be replaced.

6. If the test is complete, replace the control board

cover and close the control panel.

WARNING

F-62 F-62

COMMANDER 400

Figure F.29 Control Board Plug J1

J2

J6

J5

J8

J7

J1

J4

J22

J20

C112

-Pin #2

+Pin #3

Plug J1