Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-5 F-5

COMMANDER 400

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353 (WELD).

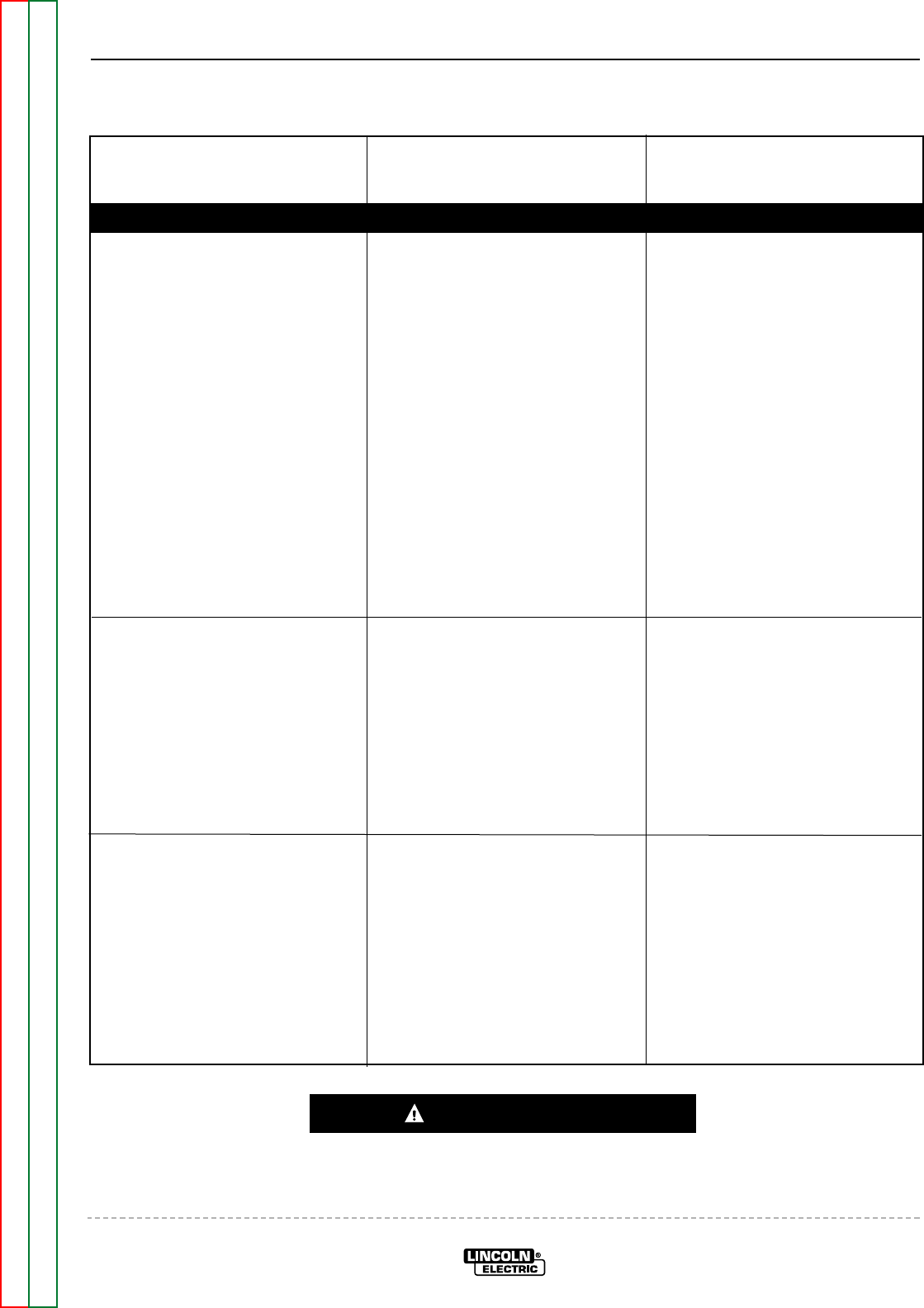

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

The welding output is low with little

or no control of output. The auxil-

iary power is OK. The engine is

operating normal.

The machine has low welding out-

put and low auxiliary output.

1. If the remote control unit is not

connected to the machine, make

sure the Local/Remote switch

(S1) is in the “Local” position.

2. If a remote control unit is con-

nected, and the machine oper-

ates normally when the switch is

in the “Local” position, the

remote control cable or unit may

be faulty. Check or replace.

1. The engine speed may be low.

Normal high idle (no load) is

1900 RPM.

1. Perform the Fine Control

Potentiometer Test.

2. Perform the Stator Voltage Test.

3. Perform the SCR/Diode Bridge

Test.

1. If the speed is low, perform the

Engine Throttle Adjustment

Test.

2. Perform the Stator Voltage Test.

3. Perform the Exciter Capacitor

Bank Test.

4. The engine may have lost horse-

power and may need major

repairs.

“---” or “CRS” stuck on display when

machine is powered up. No welding

output in both stick and CV modes.

Engine operates normally and auxil-

iary power is normal.

1. Contact your local Lincoln

Authorized Field Service shop.

1. Check for loose or faulty connec-

tions or wires at the T1, T2, or T3

capacitor connection block and

back to the capacitor bank. On

machines equipped with

L10953-1 Exciter feedback

Module Assembly check leads

T1, T2 & T3 for faulty connec-

tions.

2. Check for loose or faulty connec-

tions at leads 268,269, & 270

from the exciter PC board to J4

pins 1,2, & 3 on the control

board.

3. Check the exciter waveforms as

illustrated in the Oscilloscope

Waveforms Section.