Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-9 F-9

Commander 400

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353 (WELD).

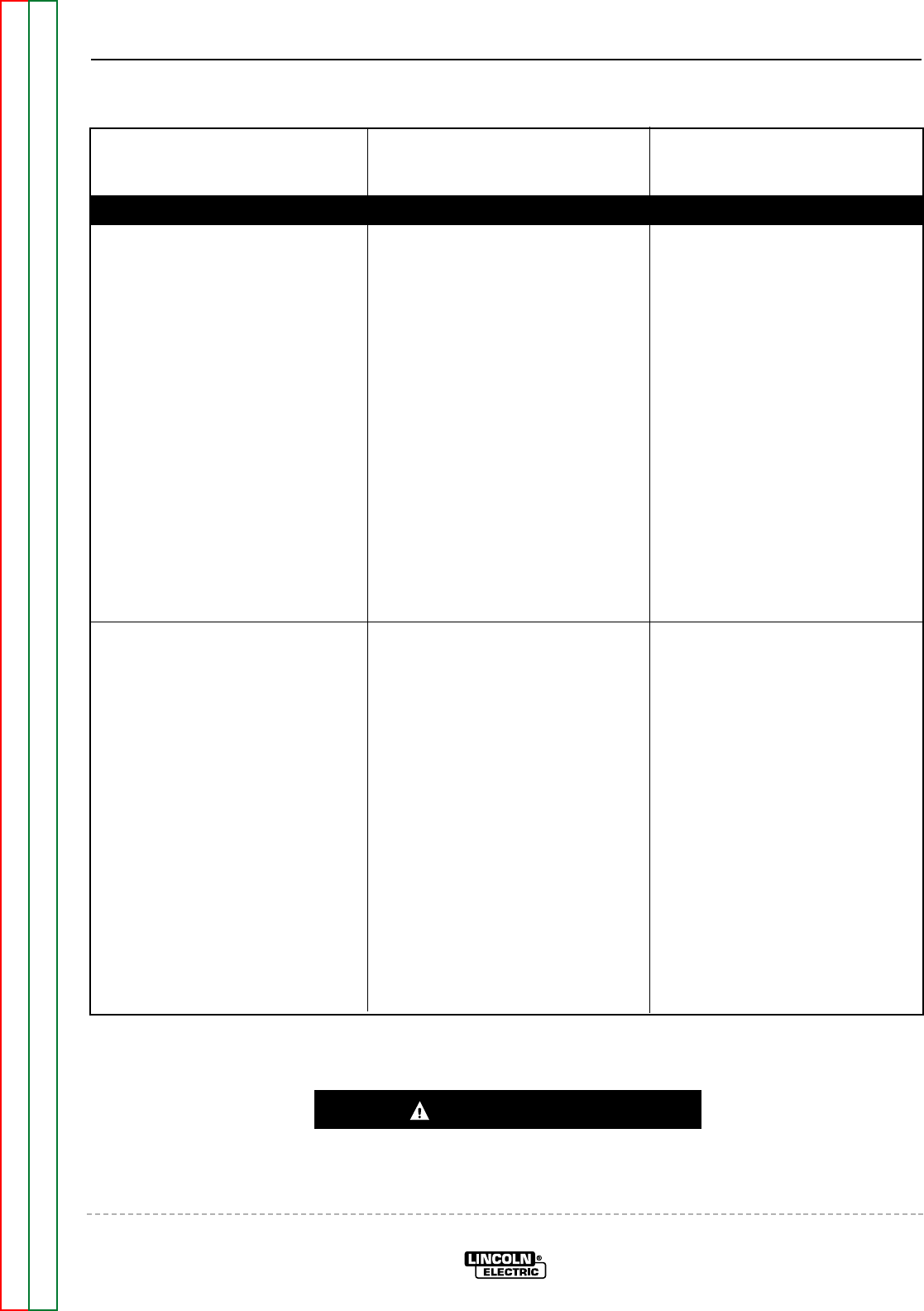

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

The machine goes to low idle but

does not stay at low idle.

1. Make sure there is NOT an

external load (auxiliary or weld)

connected to the Commander

400.

1. The idler solenoid linkage may

be misadjusted or damaged.

2. The idler solenoid hold-in circuit-

ry may be faulty. Check leads

#237 and #226 for loose or faulty

connections. See the Wiring

Diagram.

3. Perform the Idler Solenoid Test.

4. Make sure the control board

mounting/grounding screws are

tight.

5. Check solenoid waveforms as

illustrated in the Oscilloscope

Waveforms Section.

6. The control board may be faulty.

Replace.

The engine will not crank or cranks

very slowly.

1. Check for loose, faulty, or cor-

roded battery cable connections.

2. Check the leads and connec-

tions at the starter solenoid and

the start push button.

3. The battery may be faulty.

1. The starter motor, solenoid or

push button may be faulty.

Check or replace.

2. The engine may be hard to

crank due to a mechanical fail-

ure in the engine.