Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

B-5 B-5

COMMANDER 400

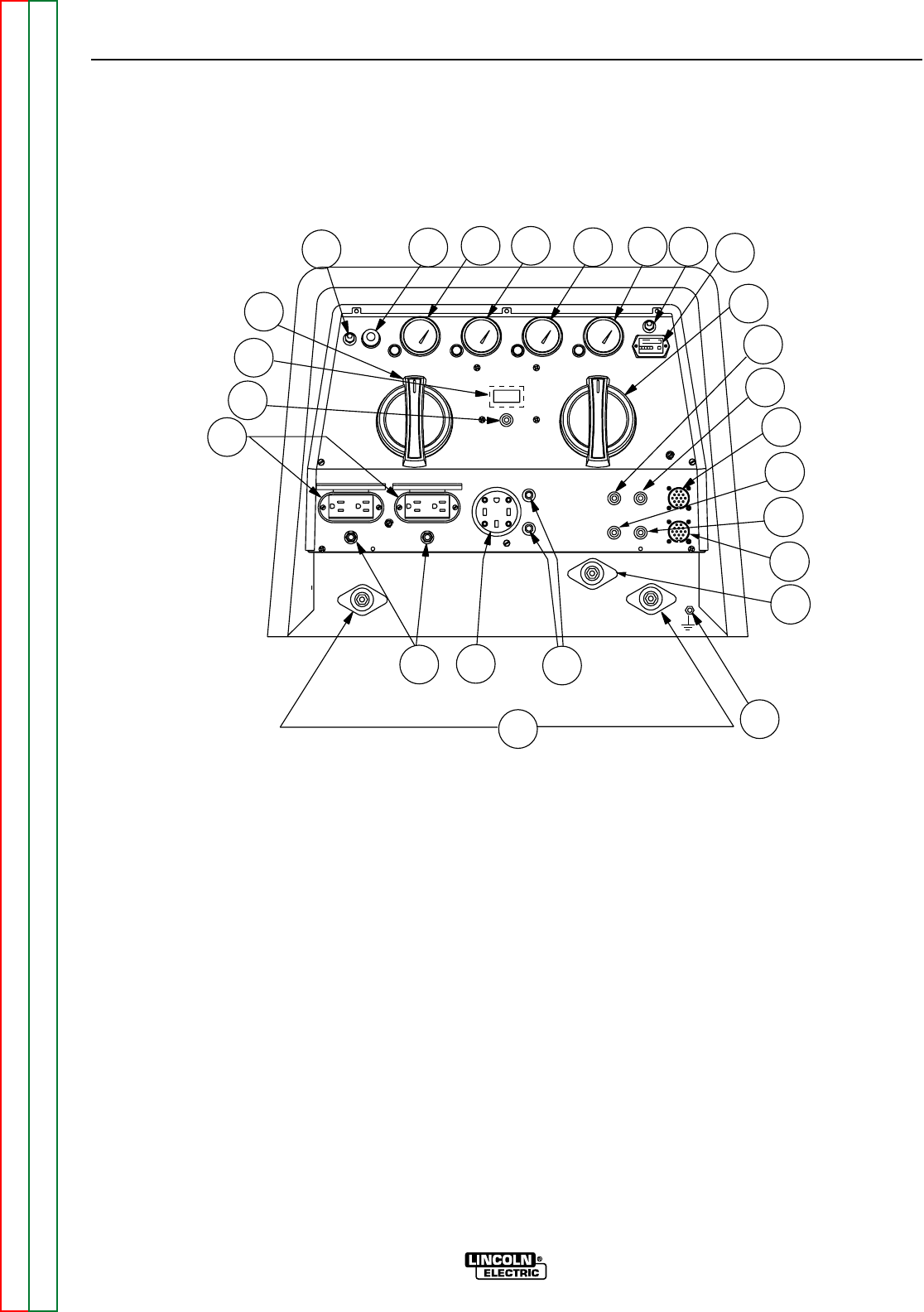

FIGURE B.1 – CASE FRONT PANEL CONTROLS

ENGINE CONTROLS

(Figure B.1, Items 1 through 8)

See Figure B.1 for the location of the following fea-

tures:

1. RUN-STOP SWITCH: When placed in the “RUN”

position, this switch energizes the fuel solenoid and

other electric accessories. When placed in the

“STOP” position, the flow of fuel to the injection

pump is stopped to shut down the engine.

NOTE: If the switch is left in the “RUN” position and

the engine is not running, the battery will be drained by

the fuel solenoid.

2. START PUSHBUTTON: Energizes the starter

motor to crank the engine. With the engine RUN-

STOP switch in the “RUN” position, push and hold

the START button for a minimum of 2 seconds to

crank the engine; release as the engine starts. Do

not press while engine is running since this can

cause damage to the ring gear and/or starter motor.

3. FUEL LEVEL GAUGE AND LIGHT: Displays the

level of diesel fuel in the 25-gallon (94.6 liter) fuel

tank. The yellow light turns on when the fuel gage

reaches the reserve level. Once the reserve level is

reached, the engine protection system will shut

down the engine after 30 minutes of operation. The

machine can be restarted and operated for an addi-

tional 30 minutes before the protection system will

shut down the engine. This ability to override the

engine protection is to allow the operator to “finish

up” if necessary. The operator must watch the fuel

level closely to prevent running out of fuel and hav-

ing to bleed the system.

CONTROLS AND SETTINGS

The welder/generator controls are located on the case

front panel. Refer to Figure B.1 and the explanations

that follow.

0

OIL

2

9

17

23

00000

8

7

16

15

18

FUEL

TEMP

4

AMPS

5

6

PRESS

9

HOURS

13

22

21

24

20

3

1

10

11

12

19

14

+-

-