TROUBLESHOOTING AND REPAIR

STATOR RESISTANCE TEST (continued)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TEST PROCEDURE

1. With the engine off, disconnect the negative bat-

tery cable. Make sure that there is nothing

plugged into the 115V and 230V receptacles.

2. Using the 5/16” nut driver, open up the control

panel and tilt out. Remove the control board

cover.

3. Refer to the “Case Cover Removal” section and

remove left side engine and stator cover panels,

and the front shroud.

4. Pull the sleeving back, and disconnect all weld

leads (W1-W6) from the SCR/Diode weld bridge

using the 7/16” nut driver and crescent wrench.

5. Locate the point at which the capacitor bank

leads are bolted to the T1,T2 & T3 leads coming

from the stator and L10953-1 exciter module.

Pull the sleeving back and disconnect the three

bolted exciter connections using a 7/16” nut dri-

ver and crescent wrench.

6. Disconnect J2 from the control board.

7. Using an Ohmmeter check for continuity

between each weld lead (W1-W6) to the T1

exciter lead. There should be no continuity

between these leads.

8. Check for continuity from the weld leads to the

J2 plug pins 1 & 2 at the control board. There

should be no continuity between these leads.

See Figure F.31.

9. Check for continuity from the weld leads to frame

ground. There should be no continuity between

these leads.

10. Check for continuity from J2 pins 1 & 4 to the T1

exciter lead. There should be no continuity

between these leads.

11. Check for continuity from J2 pins 1 & 4 to frame

ground. There should be no continuity between

these leads.

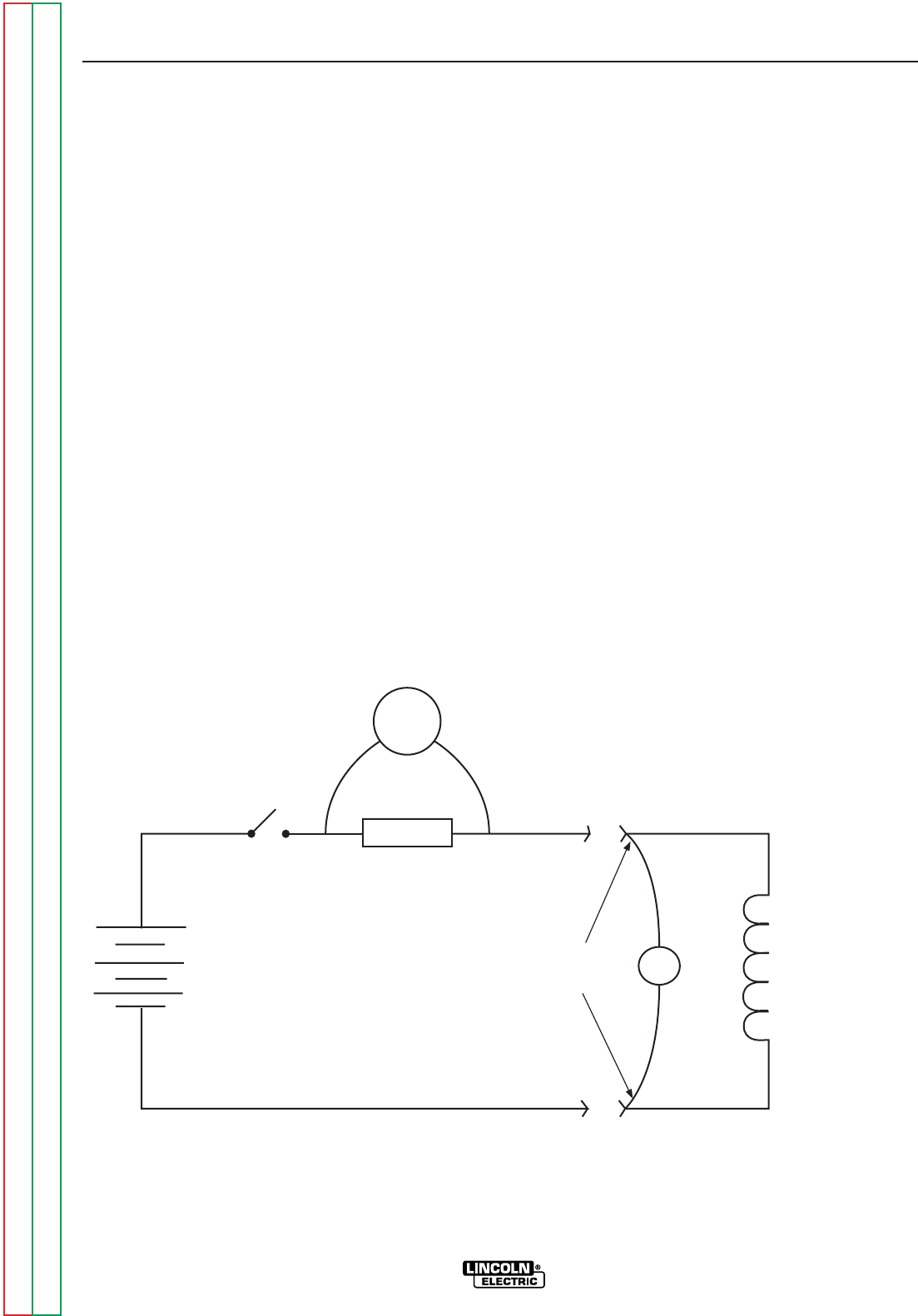

12. Construct the circuit shown below. See Figure

F.32.

F-70 F-70

J50

J51

V2

STATOR

WINDING

UNDER

TEST

VOLTAGE LEADS MUST

BE TO THE WINDING

SIDE OF THIS CONNECTION

12V

CAR

BATTERY

S1

1 OHM

300 W

V1

COMMANDER 400

Figure F.32