TROUBLESHOOTING & REPAIR

F-97 F-97

COMMANDER 400

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SCR REMOVAL AND REPLACEMENT (continued)

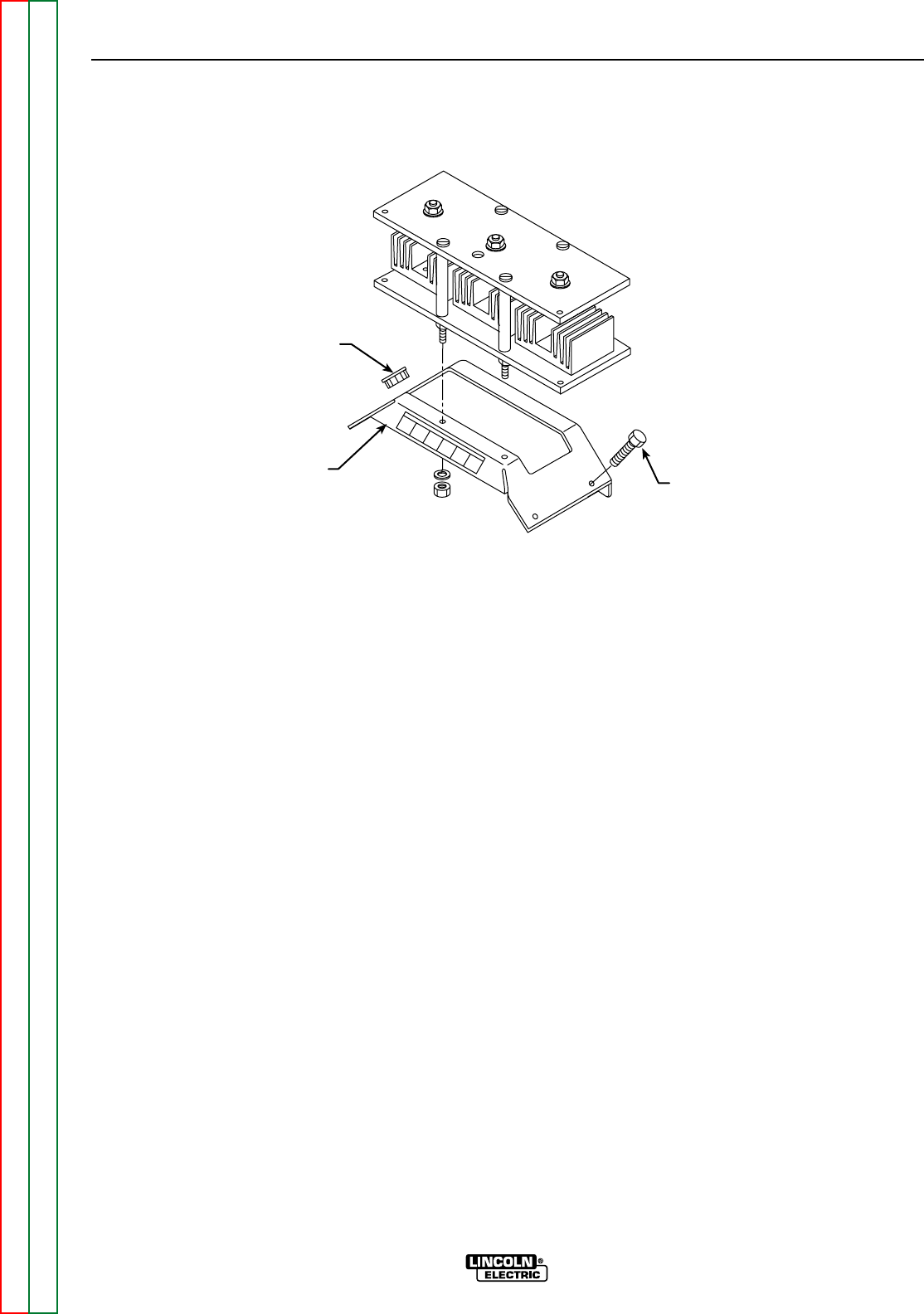

FIGURE F.44 – RECTIFIER BRIDGE ASSEMBLY BRACKET DETAILS

GROMMET

BRACKET

SCREWS (4)

PROCEDURE

1. Turn the engine off.

2. Perform the SCR/Diode Rectifier Bridge

Assembly Removal procedure.

3. Using the 7/16” wrench, remove the mounting

bracket for the SCR/diode rectifier bridge

assembly bracket. See Figure F.44.

4. Alternately loosen nuts 1/2 turn each until

heat sinks are loose. Remove nuts and leaf

spring. IT IS RECOMMENDED THAT NEW

HARDWARE, LEAF SPRING AND HOUS-

ING BE USED FOR REASSEMBLY.

5. Remove the old SCR.

6. Clean the area on the heat sink around the

SCR mounting surface, using a putty knife or

similar tool. DO NOT SCRATCH THE SCR

MOUNTING SURFACE.

7. Polish each heat sink’s mounting surface

using NO. 000 fine steel wool. Wipe surface

clean with a lint-free cloth or paper towel.

8. Inspect the mounting surfaces of each new

SCR.

a. Remove all burrs and wipe clean. Do not

use steel wool or any abrasive cleanser

on the SCR mounting surfaces.

9. Apply a thin (0.001” to 0.003”) layer of PEN-

ETROX A-13 (Lincoln Electric #E2529) or

PENETROX A, heat sink compound, to each

heat sink’s SCR mounting surface.

a. Care must be used to prevent foreign

material contamination of the SCR to

heat sink junction.

10. Place the new SCR between the heat sinks.

Be sure that the outer metal ring of the SCR

is facing toward the same heat sink as the old

SCR’s metal ring. Be sure that the roll pin of

the heat sink engages the “hole” in the SCR.

The SCR contact surfaces must sit flat

against both heat sink surfaces.