Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-8 F-8

COMMANDER 400

Observe Safety Guidelines

TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353 (WELD).

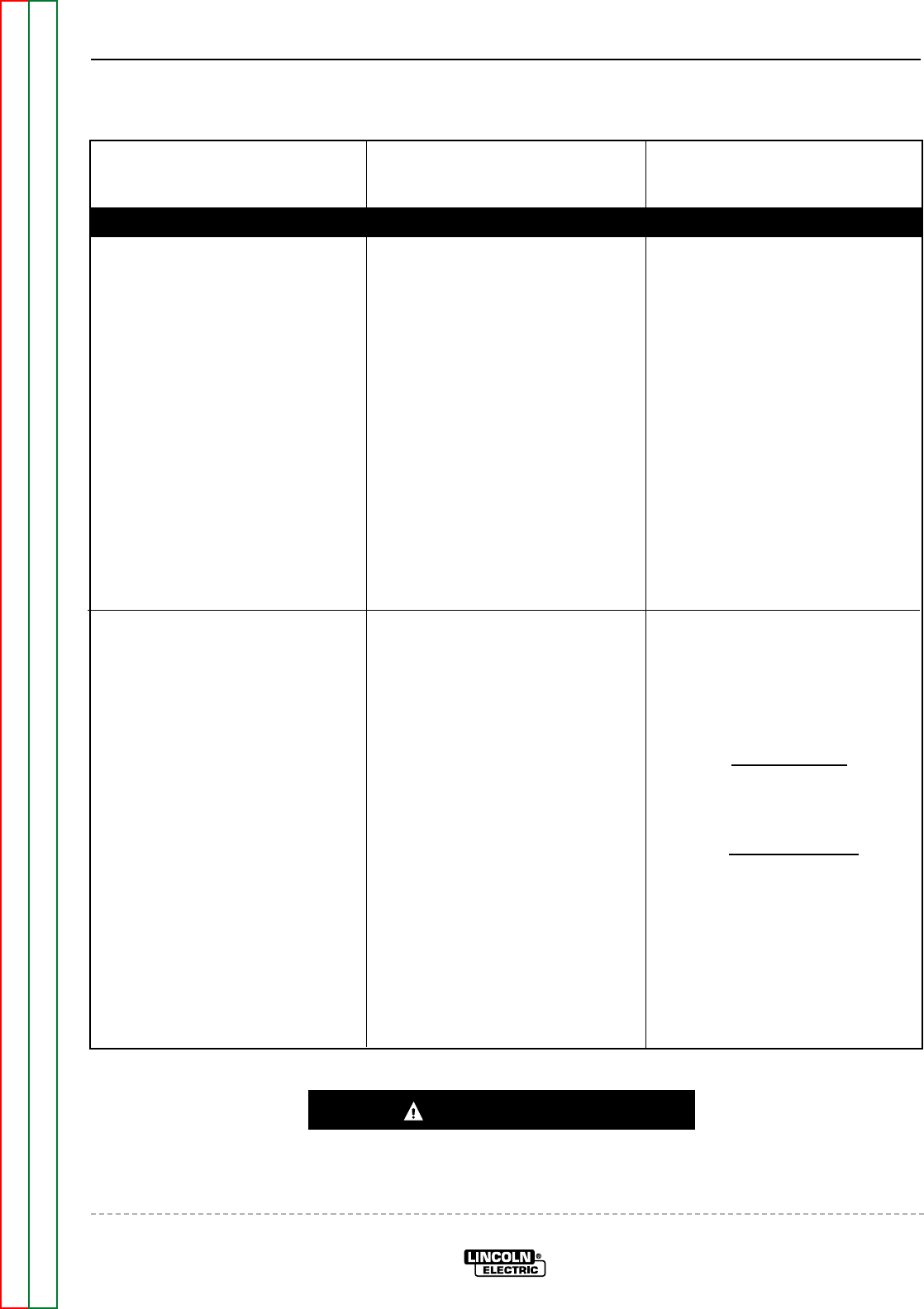

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

Engine will not idle down to low

speed. Machine has normal weld

and auxiliary power.

1. Make sure the Idler switch (S4)

is in the “AUTO” position.

2. Make sure there is not an exter-

nal load on either the weld ter-

minals or the auxiliary recepta-

cles.

3. Check for mechanical restriction

in the solenoid linkage.

1. Perform the Idler Solenoid Test.

2. Make sure the control board

mounting/grounding screws are

tight.

3. Check leads #226, #227, #237 &

#254 for loose or faulty connec-

tions. See the Wiring Diagram.

4. Check solenoid waveforms as

illustrated in the Oscilloscope

Waveforms Section.

5. Check to make sure that leads

#227 & #232 at the B1 & B3 ter-

minals on the control board are

not swapped. See the Wiring

Diagram.

Engine will not go to high idle when

attempting to weld or use auxiliary

power. Output is normal when Idler

switch is in the “HIGH” position.

Automatic idle function works prop-

erly when the auxiliary power is

loaded.

1. Make sure the welding cables

and connections are tight.

NOTE: The automatic idler may

not function if the auxiliary

power is loaded to less

than 150 watts.

1. Check the current sensing toroid

for loose or faulty connections.

CV models only. See the Wiring

Diagram.

2. Make sure the toroid and lead

assembly are assembled cor-

rectly. CV models only

. See the

Wiring Diagram.

3. Check the shunt and associated

leads for loose or faulty connec-

tions. Stick models only

.

4. The control board may be faulty.