THEORY OF OPERATION

E-4 E-4

COMMANDER 400

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

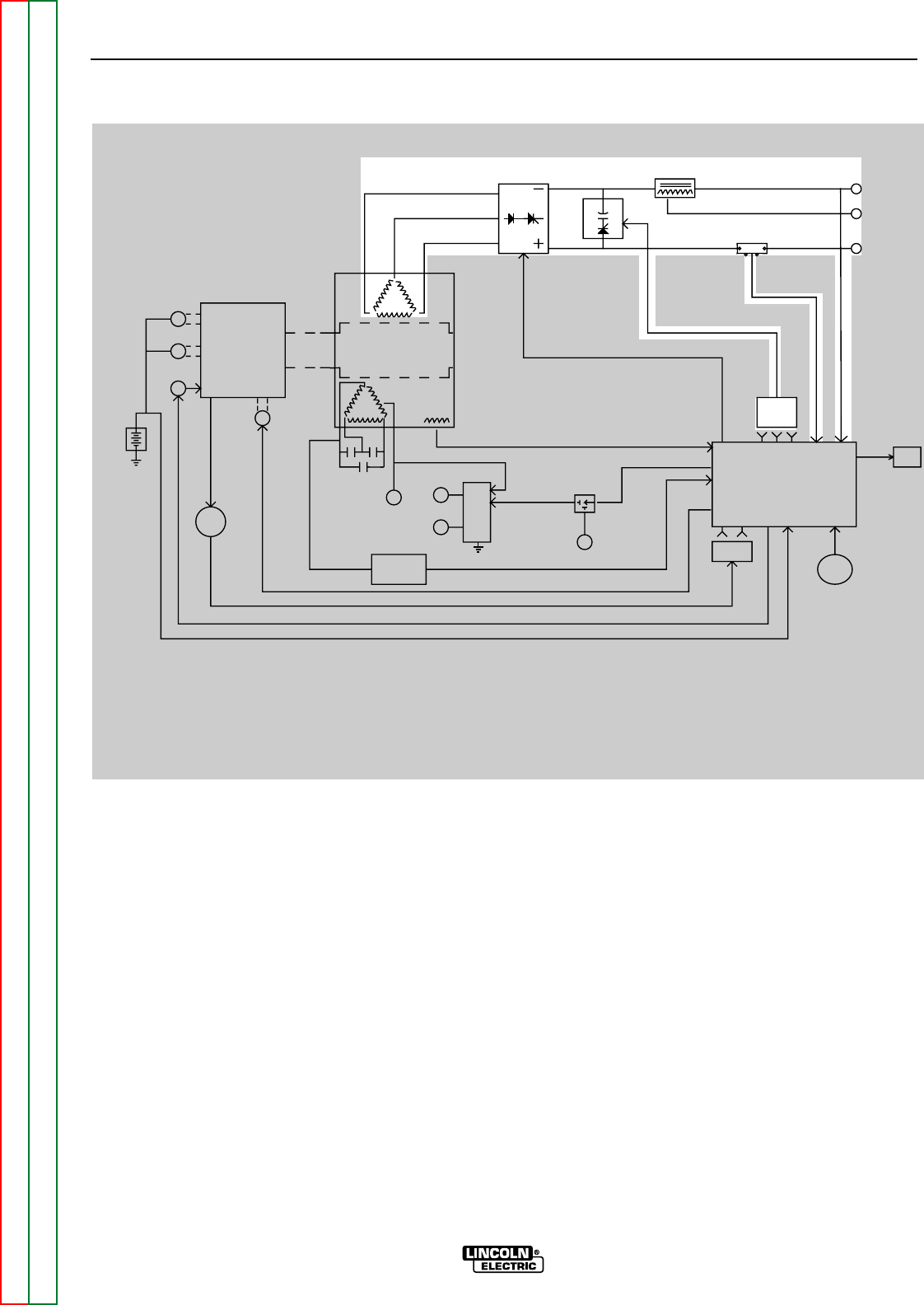

WELD WINDING, OUTPUT BRIDGE,

OUTPUT CHOKE AND CV CAPACI-

TORS

The three-phase AC output that is created in the stator

weld winding is connected to the SCR/Diode output

bridge where it is rectified and controlled. See SCR

Operation.

A choke is connected between the negative side of the

bridge and the negative output terminal. This large

inductor stores energy and provides filtering for the

welding output of the Commander 400.

In the constant voltage (CV) mode, the CV capacitors

are brought into the welding circuit via an SCR that is

activated by the CV board. These capacitors add volt-

age filtering and help maintain a constant arc voltage at

the output terminals.

1

The shunt, which is in series with the positive output

terminal, provides current feedback to the control

board.

1

CV Board and CV Capacitors are present on stick and wire

model only.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

FIGURE E.4 – WELD WINDING, OUTPUT BRIDGE, OUTPUT CHOKE AND CV CAPACITORS

ENGINE ROTOR

MECHANICAL

ROTATION

EXCITER

WINDINGS

WELD

WINDINGS

SCR/DIODE

OUTPUT

BRIDGE

OUTPUT

CHOKE

CV

CAPAC

ITORS

SHUNT

POSITIVE

TERMINAL

CV

TERMINAL

TERMINAL

NEGATIVE

EXCITER

CAPACITORS

115/230VAC

RECEPTACLE

14 PIN

AMPHENOL

6 PIN

AMPHENOL

EXCITER VOLTAGE

FEEDBACK

BOARD

ENGINE

PROTECTION

BOARD

CURRENT/ MODE

SELECTOR

SWITCH

BATTERY

STARTER

ALTERNATOR

SHUTDOWN

SOLENOID

IDLER

SOLENOID

SENSORS

ENGINE

FINE

OUTPUT

CONTROL

BY-PASS

PC

BOARD

METER

CV

BOARD

MAIN

CONTROL

BOARD

REMOTE

SWITCH

42VAC

12VDC

SCR GATE SIGNALS

115VAC

FEEDBACK

F

E

E

D

B

A

C

K