A-8

INSTALLATION

POWER WAVE 455/POWER FEED 10

A-8

CONTROL CABLE SPECIFICATIONS

The cable is a five copper conductor cable in a SO-

type rubber jacket. There is one 20 gauge twisted

pair for network communications. This pair has an

impedance of approximately 120 ohms and a propa-

gation delay per foot of < 2.1 ns. There are two 12

gauge conductors that are used to supply the 40

VDC to the network. The fifth wire is 18 gauge and is

used as an electrode sense lead. It is typically con-

nected to the feed plate on the feed head when that

feed head is active.

AVAILABLE CABLE ASSEMBLIES

K1543 Control cable only. Available in lengths of

8, 16, 25, 50 and 100 feet.

K1544 Control cable and a 3/0 (85 mm

2

) electrode

cable with stud terminal. It is rated at 600

amps, 60% duty cycle and is available in

lengths of 8, 16, 25, and 50 feet.

K1545 Control cable and a 3/0 (85 mm

2

) electrode

cable with Twist-Mate™ connector on one

end and a stud terminal on the other. It is

rated at 500 amps, 60% duty cycle and is

available in lengths of 8, 16, 25, and 50 feet.

CABLE CONNECTIONS

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work or wire feeder. Avoid

excessive lengths, bundle the electrode and ground

cables together where practical, and do not coil

excess cable. Be sure the connection to the work

makes tight metal-to-metal electrical contact.

Minimum work and electrode cables sizes are as fol-

lows:

When using an inverter type power source, use the

largest welding (electrode and ground) cables that

are practical. At least 2/0 copper wire — even if the

average output current would not normally require it.

When pulsing, the pulse current can reach very high

levels. Voltage drops can become excessive, lead-

ing to poor welding characteristics, if undersized

welding cables are used.

ELECTRODE AND WORK LEADS —

ELECTRODE POSITIVE APPLICATIONS

Most welding applications run with the electrode

being positive (+). For those applications, connect

the electrode cable between the wire feeder and the

positive (+) output stud on the power source (located

beneath the spring loaded output cover near the bot-

tom of the case front). See Figure A.3.

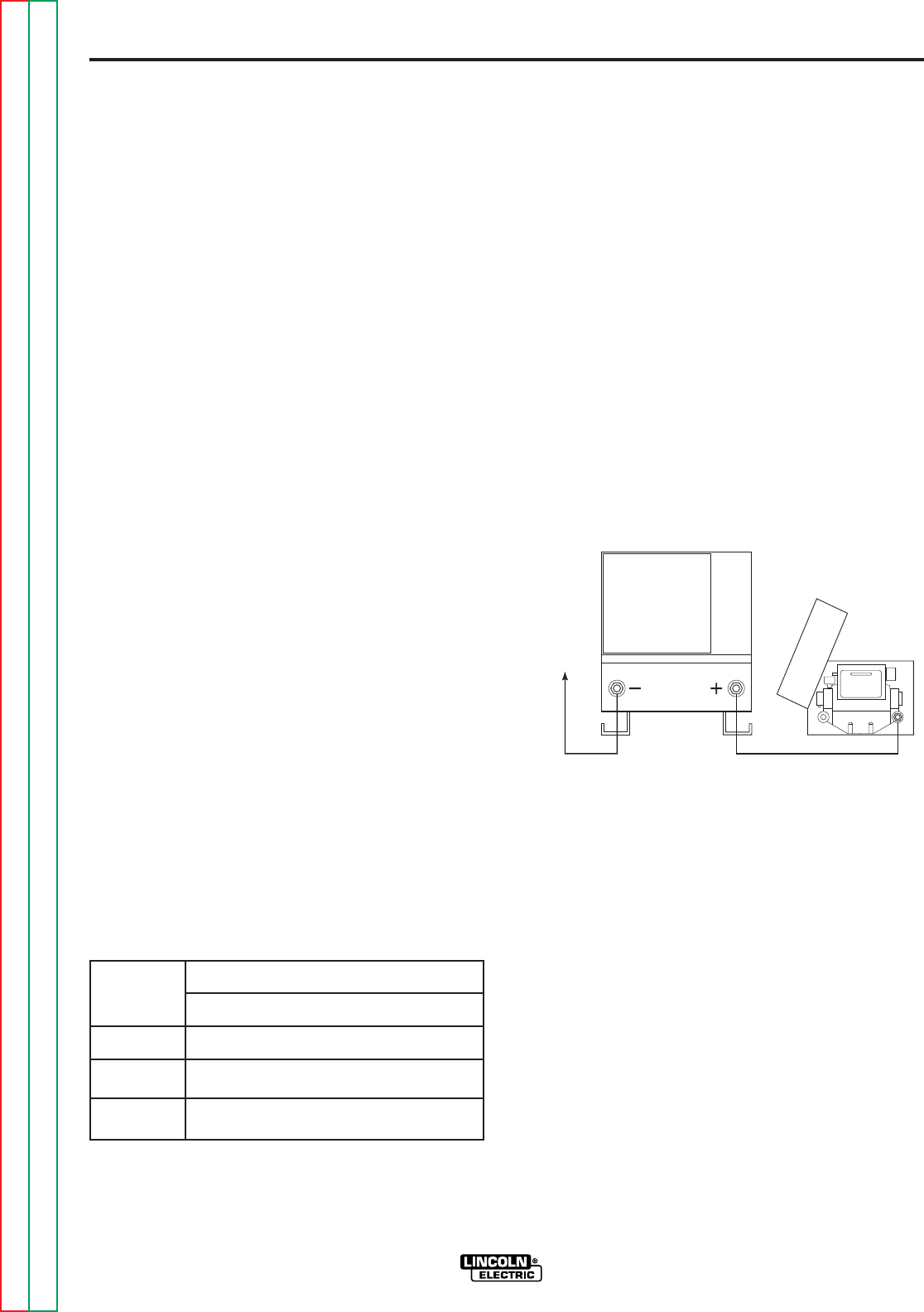

FIGURE A.3 — ELECTRODE POSITIVE

APPLICATION.

A work lead must be run from the negative (-) power

source output stud to the work piece. The work

piece connection must be firm and secure, especially

if pulse welding is planned. Excessive voltage drops

at the work piece connection often result in unsatis-

factory pulse welding performance.

Minimum Copper Work Cable Size, AWG

Up to 100 ft Length (30m)

Current

60% Duty

Cycle

400 Amps

500 Amps

600 Amps

2/0 (67 mm

2

)

3/0 (85 mm

2

)

3/0 (85 mm

2

)

POWER WAVE

WIRE

FEEDER

TO

WORK

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC