A-11

INSTALLATION

POWER WAVE 455/POWER FEED 10

A-11

DIP SWITCH SETUP

SETTING DIP SWITCHES IN THE

CONTROL BOX

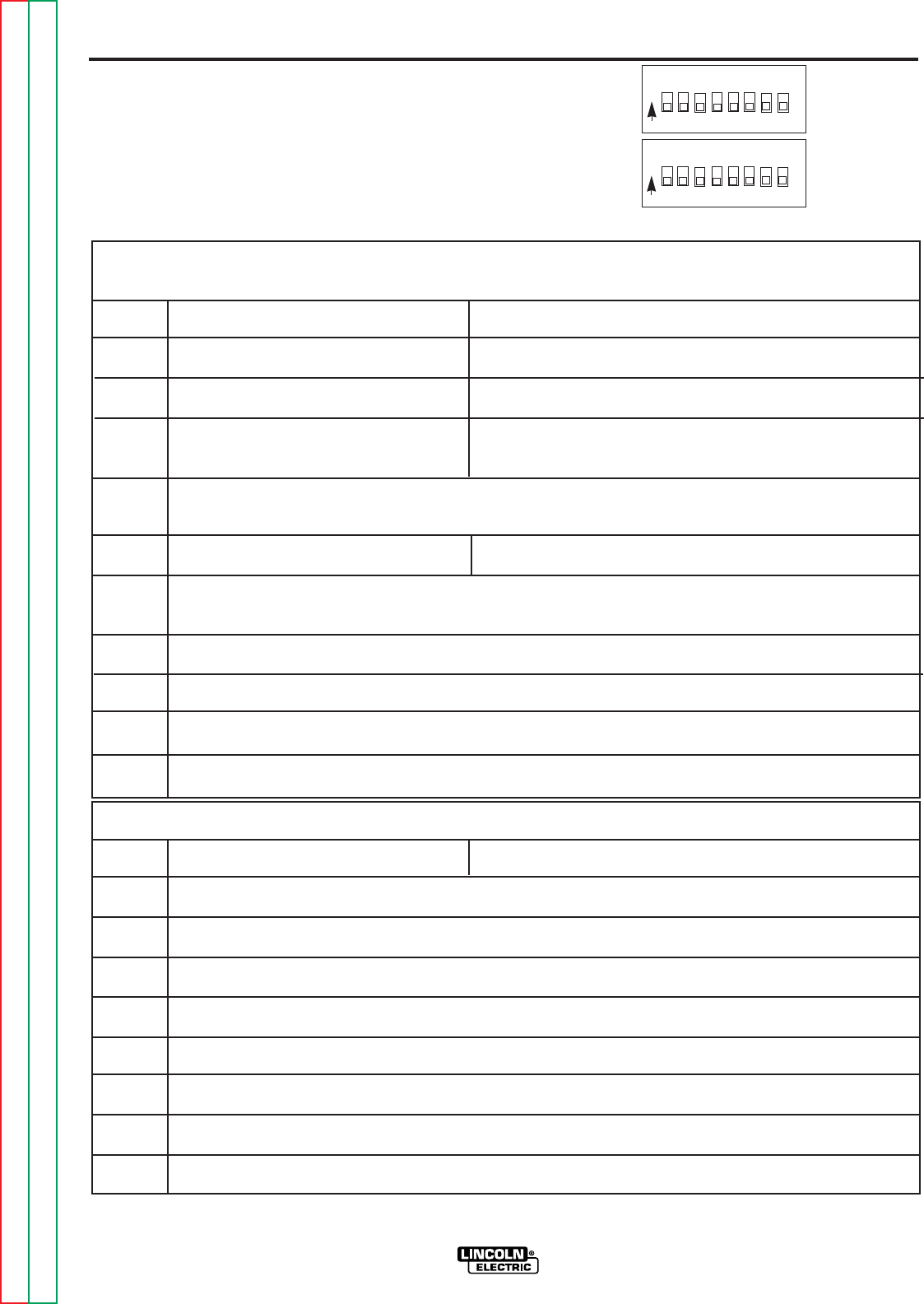

There are two DIP switch banks on the mother board

of the Control Box. They are labeled S1 and S2 and

are located and oriented as shown in Figure A.3.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE A.3

S1

ON

1 2 3 4 5 6 7 8

S2

ON

1 2 3 4 5 6 7 8

S1 DIP Switch Bank on Control Box Motherboard (For software version S24004-2 only)

Switch Off On

1 US 4-Step Trigger Logic Euro 4-Step Trigger Logic

2 WFS Display = inches/minute WFS Display = meters/minute

3 Left Display is always preset WFS Left Display is preset WFS when weld current is not flowing

Left Display is actual weld current when weld current is flowing

CC modes override this switch regardless of position. Left Display is always preset weld cur-

rent when weld current is not flowing and actual weld current when weld current is flowing

4 Run-in = Minimum Speed Available Run-in = weld WFS

If any option containing a Run-in setting is connected to the motherboard, it automatically

overrides this switch regardless of position.

5 Spare

6 Acceleration, MSB (Sets acceleration rate for wire drive) see below

7 Acceleration (Sets acceleration rate for wire drive) see below

8 Acceleration, LSB (Sets acceleration rate for wire drive) see below

S2 DIP Switch Bank on Control Box Motherboard (For software version S24004-2 only)

Switch Off On

1 Network Group ID, MSB (Assigns Control Box to a specific group) (Off is factory setting)

2 Network Group ID, LSB (Assigns Control Box to a specific group ) (Off is factory setting)

3 Spare

4 Spare

5 Spare

6 Spare

7 Spare

8 Reserved

Note: the factory shipped settings for all of the S1 and S2 switches is “OFF”.