TROUBLESHOOTING AND REPAIR

F-93

POWER WAVE 455/POWER FEED 10

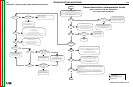

FLOWCHART - POWER SOURCE ERROR INTERPRETATION GUIDE

Code 12?

Start

Codes 21,

22, or 23?

Code 36?

Code 31?

Codes 32, 33, 34,

and 35?

UI previously recognized by the system is no

longer communicating, but power appears to

be present at the UI. Check for intermittent

connections in the communication path

(pins A and B in the control cable, wires 541

and 542 in both the UI and FH).

UI Display and

Status light on?

UI previously recognized by the system is no

longer communicating, and no power appears to

be present at the UI. Check for intermittent

connections in the +40 VDC path (pins D and E

in the control cable, wires 540 and 500 in both

the UI and FH).

Weld Table Error is present.

Reload known good Weld Software.

Check the "All Modes" dipswitch in the UI, typically

SW2-8 (refer to dipswitch settings specified for the

software version loaded in the UI).

Thermal Error (generally accompanied by a thermal error light):

Check continuity of thermostat circuit. Thermostats are connected

in series, so open circuit reading indicates tripped thermostat or

faulty connection

Check operation of the cooling fan.

Check for excessive dirt build up in heatsink fins etc.

Perform Output

Rectifier Test

Replace Output

Rectifier Modules as

Required

The current transformer (CT)

feedback signal to the control

board is too high. Look for a

short in the transformer or

primary side of the machine.

Perform the Switch

Board Test on both

sides.

Replace as Necessary.

Replacement board(s) must have

identical part number (including the

"dash number").

Code 32 and

33?

Code 34 and

35?

Both Switch boards are reporting an undervoltage error.

Check Input Voltage.

Perform the Input Board Test.

Check for proper reconnect position.

Look for faulty undervoltage connections from the Switch board(s) to the

Control board (+5VDC = normal, 0VDC = fault).

If the symptom is intermittent, Check the operation of the main contactor.

Both Switch boards are reporting an overvoltage error.

Check the Input Voltage.

Check for proper reconnect position.

Look for faulty overvoltage connections from the Switch

board(s) to the Control board

(+5VDC = normal, 0VDC = fault).

Machine configured

for 230V?

Invalid error combination. Check for

faulty overvoltage and undervoltage

connections from the Switch

board(s) to the Control board

(+5VDC = normal, 0VDC = fault).

Code 32 and

34?

Code 33 and

35?

Perform the Switch Board

Test on Side "A" (left side

facing the front of

machine)

Perform the Switch Board

Test on Side "B" (right

side facing the front of

machine)

Replace the Switch Board

Replacement board(s) must have

identical part number (including

the "dash number").

Replace the Switch

BoardReplacement board(s)

must have identical part number

(including the "dash number").

Check main capacitor for a short circuit

condition.

Check for faulty overvoltacge and

undervoltage connections from the Switch

board(s) to the Control board

(+5VDC = normal, 0VDC = fault).

N

Y

Y

Y

N

Y

Y Pass

Fail

Y

Fail

N

Y

Y

N

N

Y

N

Y

Fail

Pass

N

Y Pass

Fail

N

Any of the following

codes:

32, 33, 34, or 35?

Code 37?

Soft Start failure.

Generally accompanied by under and over voltage errors

(32-35), because the system is unable to charge the

main capacitors to an acceptable voltage level.

Follow the branch for under and over voltage errors

(32-35) to test the Input Bd., Switch Bd., and main

contactor operation.

Finish

Y

N

N

N

N

N

Power Source Error Interpretation Guide

Error codes that contain three or four digits are defined as fatal errors. These codes

generally indicate internal errors on the PS Control Board. If cycling the input power on

the machine does not clear the error, try reloading the operating system. If this fails,

replace the control board.

EXCEPTION:

Reoccuring fatal errorscan sometimes be caused by overloading the system. As an

example this could occur in earlier versions of PS software when rapidly changing from

one head to the another on a multi-head system (i.e. PF10x2). Adding a minimum (0.1

seconds) of preflow time to each head or upgrading the operating system shoudl

generally solve the problem.

Other Codes?

N

Y

(Semi Automatic PW-455, PW455/STT)

If the PS Status light is flashing any combination of red and green,

errors are present in the PW-455.

Error Code interpretation through the Status light is detailed in the

Service Manual. Individual code digits are flashed in red with a long

pause between digits. If more than one code is present, the codes

will be se

p

arated b

y

a

g

reen li

g

ht.

Key:

PS = Power Source

UI = User Interface (Control

Box)

FH = Feed Head

Perform the Contactor Test.

Perform Input Board Test.

Perform the Input Rectifier Test.

Pass

(For Codes 10555 and Below)

F-93

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC