F-8

TROUBLESHOOTING AND REPAIR

F-8

POWER WAVE 455/POWER FEED 10

POWER WAVE

Observe all Safety Guidelines detailed throughout this manual.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric

Service Department for technical troubleshooting assistance before you proceed. Call 216-383-2531 or 1-800-833-9353.

-----------------------------------------------------------------------------------------------------------------------------

CAUTION

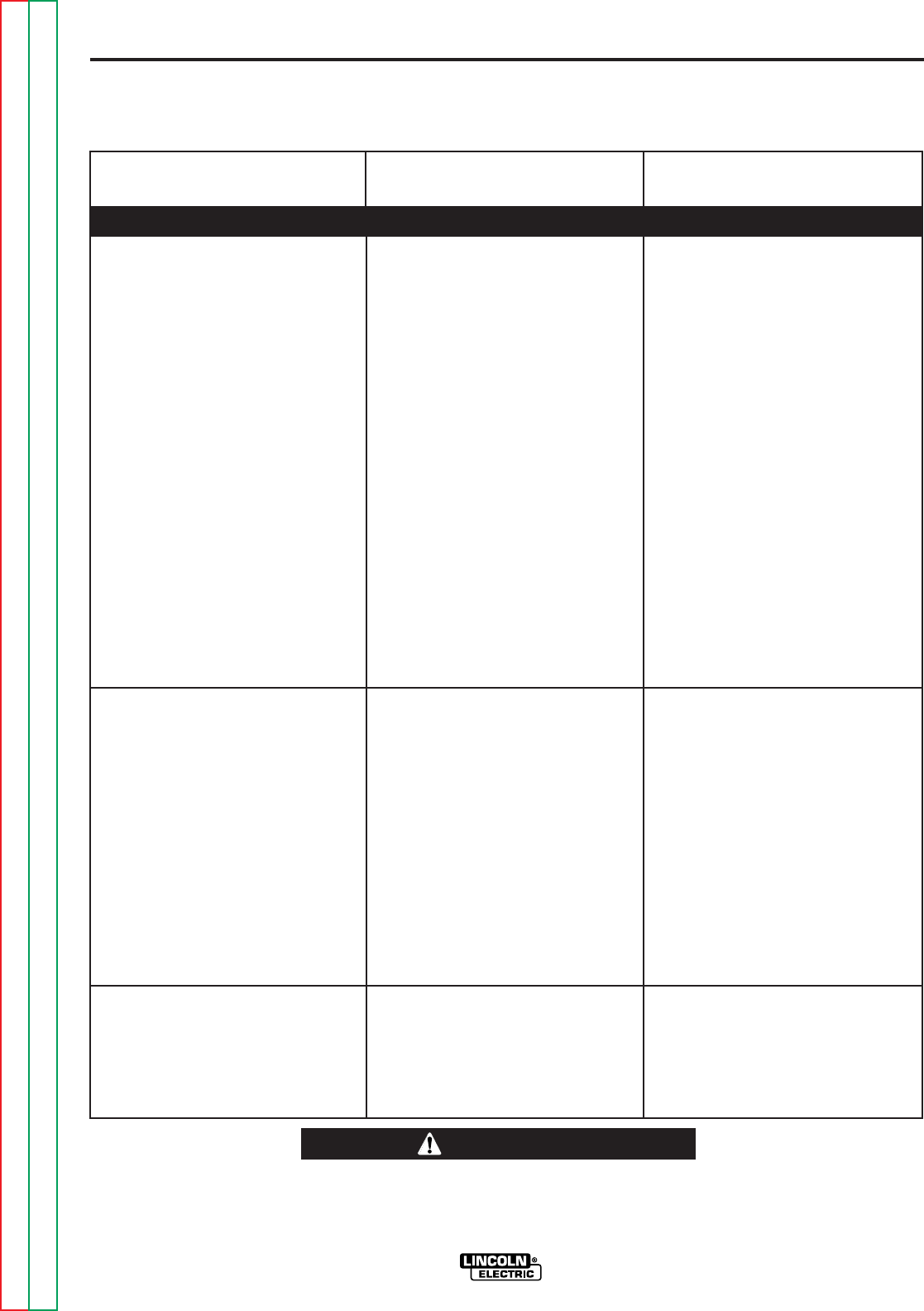

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

For no apparent reason, the weld-

ing characteristics have changed.

The machine often “noodle welds”

with a particular procedure.

The arc burns back to the tip.

1. Check for proper wire feed

speed setting. In the MIG/MAG

and FCAW modes, check for

proper voltage settings. In the

MIG/MAG pulse modes, check

the arc length trim setting.

These controls are on the

Control Box (user interface).

2. Check for proper shielding gas

and gas flow.

3. Check for loose or faulty weld-

ing cables and connections.

1. The machine may be trying to

deliver too much power. When

the average output current

exceeds a maximum limit, the

machine will “phase back” to

protect itself. Adjust the proce-

dure or reduce the load to lower

the current draw from the Power

Wave 455 machine.

Power Wave 455 - When the

average output current exceeds

570 amps, the output current is

phased back to 100 amps.

1. The voltage settings may be too

high for the procedure.

2. The voltage sensing lead or con-

nection may be faulty. See the

Power Feed 10 Wiring Diagram

1. If zero arc voltage is displayed

on the Control Box while weld-

ing, the voltage sense leads

may be broken. Check lead #67

at the wire drive. See wiring

diagram. Also check leads

#202 (Neg. output terminal) and

#206 (Pos. output terminal).

See Power Wave 455 wiring

diagram. If external voltage

sensing is utilized, check the

#21 lead between the 4-pin

receptacle on the Power Wave

455 and the workpeice.

2. Perform the

Output Rectifier

Test.

3. The control board may be faulty.

4. Perform the

Current Trans-

ducer Test.

1. Perform the

Current Trans-

ducer Test.

2. The control board may be faulty.

1. Perform the

Voltage Sense PC

Board Test.

WELDING PROBLEMS

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC