B-8

OPERATION

B-8

TO MOUNT 10 TO 44 LB (4.5 TO 20

KG) SPOOLS [12 IN. (300 MM)

DIAMETER] OR 14 LB (6 KG)

INNERSHIELD COILS (FIGURE B.4):

The spindle should be located in the LOWER

mounting hole.

(For 8 in. (200 mm) spools, a K468 spindle adapter

must first be slipped onto spindle.)

(For 13 to 14 lb (6 kg) Innershield coils, a K435 coil

adapter must be used).

1. Depress the release bar on the retaining collar

and remove it from the spindle.

2. Place the spool on the spindle making certain the

spindle brake pin enters one of the holes in the

back side of the spool. Be certain the wire comes

off the reel in a direction so as to de-reel from the

bottom of the coil.

3. Re-install the retaining collar. Make sure that the

release bar “pops up” and that the collar retainers

fully engage the retaining groove on the spindle.

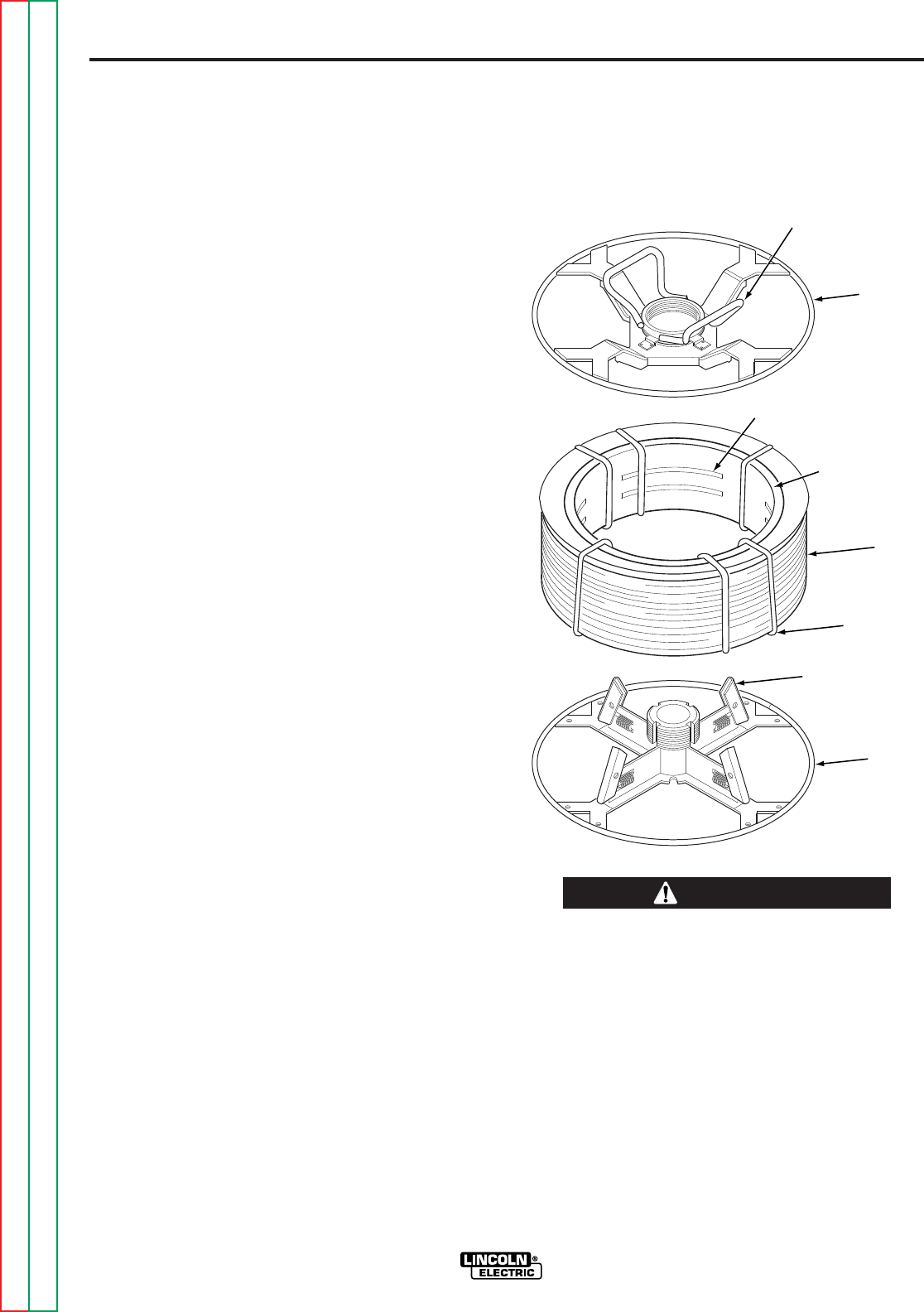

TO MOUNT A 50 TO 60 LB (22.7 TO

27.2 KG) COIL (USING K1504-1 COIL

REEL) (FIGURE B.5):

NOTE: (For 50 to 60 lb Readi-Reels a K438

Readi-Reel adapter must be used).

The spindle must be located in the UPPER mounting

hole.

1. With the K1504-1 coil reel mounted on to the 2 in.

(51 mm) spindle (or with reel laying flat on the

floor) loosen the spinner nut and remove the reel

cover. See Figure B.5.

2. Before cutting the tie wires, place the coil of elec-

trode on the reel so it unwinds from the bottom as

the reel rotates. The slots in the cardboard liner

should align over the spring loaded arms.

3. Tighten the spinner nut against the reel cover as

much as possible by hand using the reel cover

spokes for leverage. DO NOT hammer on the

spinner nut arms.

4. Cut and remove only the tie wire holding the free

end of the coil. Hook the free end around the rim

of the reel cover and secure it by wrapping it

around. Cut and remove the remaining tie wires.

FIGURE B.5 — K1504-1 COIL REEL.

Always be sure the free end of the coil is securely

held while the tie wires are being cut and until the

wire is feeding through the drive rolls. Failure to do

this will result in “backlashing” of the coil, which may

tangle the wire. A tangled coil will not feed so it must

either be untangled or discarded.

-----------------------------------------------------------

5. Be sure the coil reel is engaged with the spindle

brake pin and the release bar on the retaining col-

lar “pops up” and that the collar retainers fully

engage the retaining groove on the spindle.

POWER WAVE 455/POWER FEED 10

CAUTION

SPINNER NUT

COVER

PLATE

SLOTS

CARDBOARD

COIL LINER

COIL

TIE WIRE

SPRING

LOADED ARM

REEL

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC