F-17

TROUBLESHOOTING AND REPAIR

F-17

POWER WAVE 455/POWER FEED 10

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric

Service Department for technical troubleshooting assistance before you proceed. Call 216-383-2531 or 1-800-833-9353.

-----------------------------------------------------------------------------------------------------------------------------

CAUTION

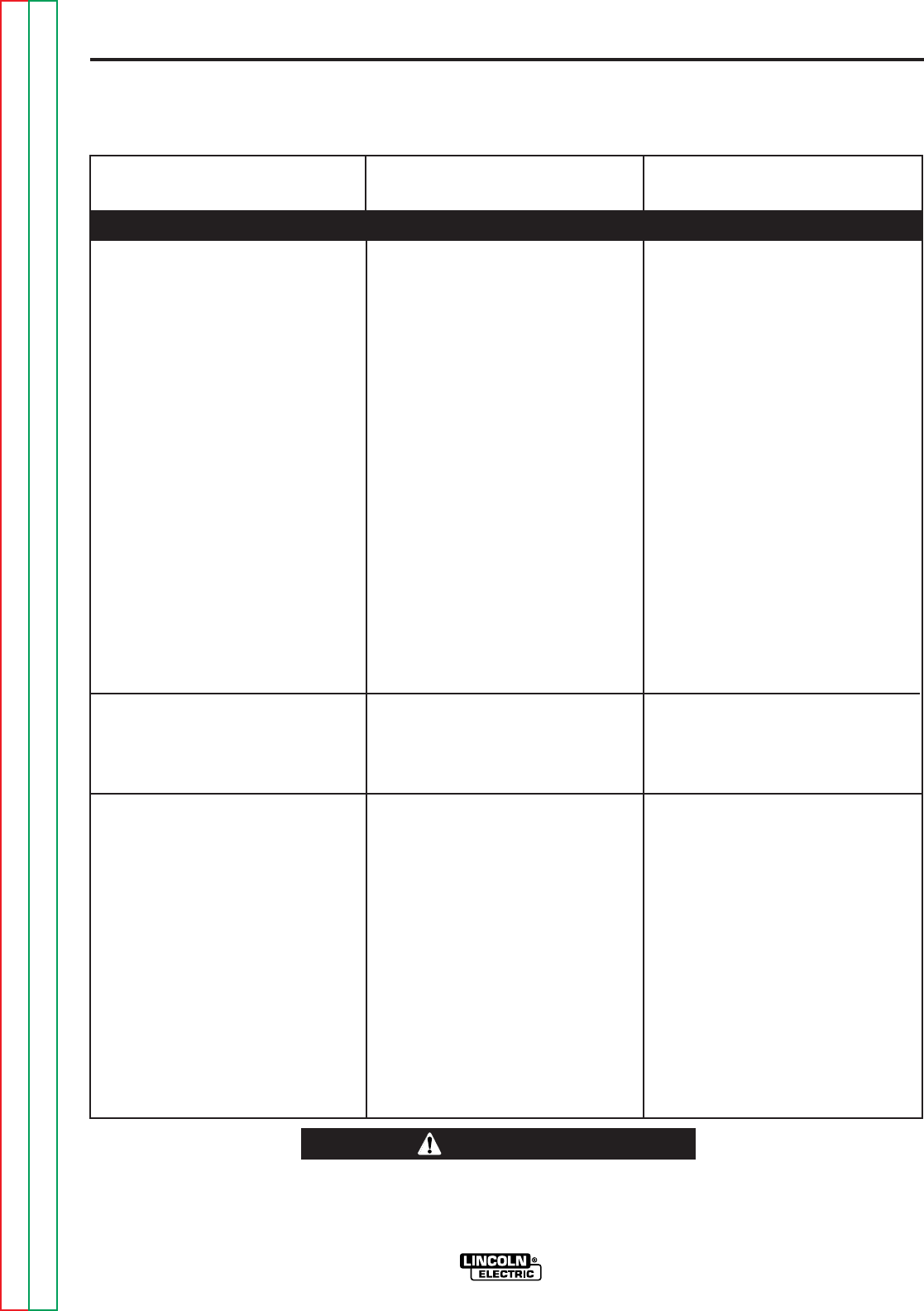

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

The Dual Procedure is not func-

tioning when using the local Dual

Procedure switch on the Control

Box. The STATUS LEDs are

steady green on the power source,

Control Box and wire drive units.

The wire feed speed is consistent

and adjustable, but runs at the

wrong speed.

The unit shuts off while welding or

attempting to weld. The STATUS

LED is alternating between red and

green every second. The unit tries

to recover after 30 seconds and

may repeat sequence.

1. Check the leads and plug J5

between the switch and the

Control Box control board for

loose or faulty connections.

See wiring diagram.

1. The DIP switch on the wire drive

unit may not be set for the cor-

rect gear ratio. See the

Instal-

lation

section of this manual.

1. The shut down circuit in the

wire drive unit may be electrical-

ly “open”. Make sure leads

#570 and #571 are connected

together.

2. The drive motor may be over

loaded due to a mechanial

restriction in the wire feeding

path. See

Operation

section of

this manual.

1. The local dual procedure switch

may be faulty.

Remove power to the machine.

Disconnect plug J5 from the

Control Box control board.

Check for continuity (less than

one ohm) between pins 1 and 7

when the Dual Procedure switch

is in position “A”. Next check for

continuity (less than one ohm)

between pins 1 and 8 when the

Dual Procedure switch is in the

“B” position. If either of these

continuity tests fail, replace the

switch. When the switch is in

the center position, there should

not be any continuity between

pins.

2. The Control Box control board

may be faulty.

1. The wire drive control board

may be faulty.

1. Disconnect any shutdown

device from leads #570 and

#571 (0.25 in. insulated tab ter-

minals). Connect leads #570

and #571 together. If the feeder

STATUS LED is now steady

green, the problem is in the

external shutdown circuit.

2. If there are no restrictions in the

wire feeding path, the drive

motor or gear box may be faulty.

3. The wire drive control board

may be faulty.

FUNCTION PROBLEMS (Continued)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC