6. Installation

6 - 12

The following shows a calculation example for considering heat radiation countermeasures.

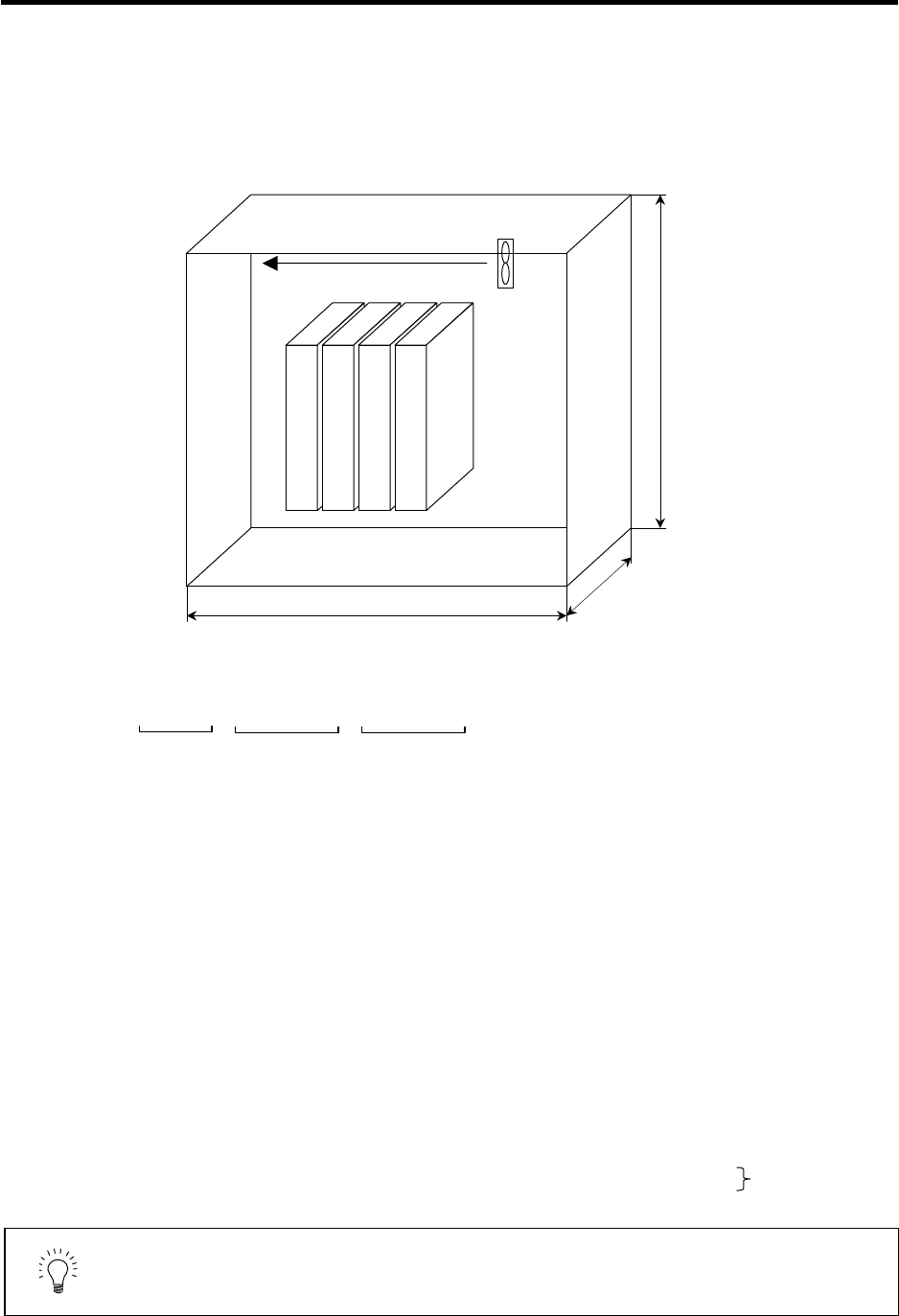

<Control panel outline dimension (assumption) >

When installing four units which have the heating value in the panel of 15W

Top of panel inside Fan for agitating

600

300

600

Heat radiation area (A): When a bottom section contacts with a machine

A = 0.6 x 0.3 + 0.6 x 0.6 x 2 + 0.6 x 0.3 x 2 = 1.26 (m

2

)

(Top face) (Front/back face) (Side face)

*Actually, sections contacting other objects are excluded.

Heating value in panel (W): when installing four units which are 15W

W = 15 x 4 = 60 (W)

<Considering necessity of agitating fan>

1 Temperature standard

(1) Standard of temperature in panel (around each unit) T 55°C

(2) External peripheral temperature Ta = 0 to 45°C

(3) Internal temperature rise value T = T - Ta(MAX) = 10°C

2 C

ooling capacity of control panel (W1)

W1 = U x A x T T = Internal temperature rise value (=10°C)

U = 6W/m

2

°C (with internal agitating fan)

4W/m

2

°C (without internal agitating fan)

A = Effective heat radiation area (m

2

)

(1) With internal agitating fan W1 = 6 x 1.26 x 10 = 75.6 (W) > 60 (W)

Internal fan is

required.

(2) Without internal agitating fan W1 = 4 x 1.26 x 10 = 50.4 (W) < 60 (W)

POINT

Measure an actual internal temperature, and install a fan or heat exchanger

which agitates the heat at the top of the unit if the temperature rise exceeds

10°C.